Critical load factors apply to all flight maneuvers except unaccelerated straight flight where a load factor of 1 G is always present. Certain maneuvers considered in this section are known to involve relatively high load factors.

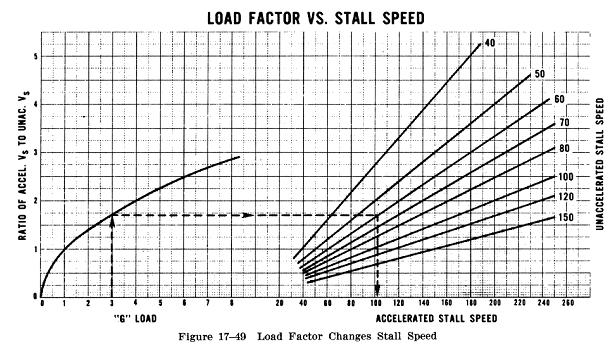

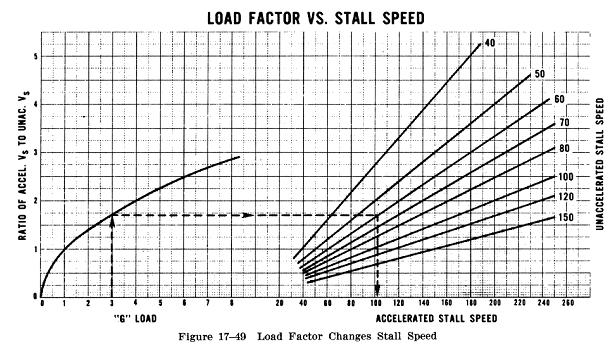

TURNS. Increased load factors are a characteristic of all banked turns. As noted in the section Load Factors in Steep Turns and particularly Figs. 17-48 and 17-49, load factors become significant both to flight performance and to the load on wing structure as the bank increases beyond approximately 45 degrees.

The yield factor of the average light plane is reached at a bank of approximately 70 to 75 degrees, and the stalling speed is increased by approximately one-half at a bank of approximately 63 degrees.

STALLS. The normal stall entered from straight level flight, or an unaccelerated straight climb, will not produce added load factors beyond the 1 G of straight and level flight. As the stall occurs, however, this load factor may be reduced toward zero, the factor at which nothing seems to have weight; and the pilot has the feeling of "floating free in space." In the event recovery is effected by snapping the elevator control forward, negative load factors, those which impose a down load on the wings and raise the pilot from the seat, may be produced.

During the pullup following stall recovery, significant load factors sometimes are induced. Inadvertently these may be further increased during excessive diving (and consequently high airspeed) and abrupt pullups to level flight. One usually leads to the other, thus increasing the load factor. Abrupt pullups at high diving speeds may impose critical loads on airplane structures and may produce recurrent or secondary stalls by increasing the angle of attack to that of stalling.

As a generalization, a recovery from a stall made by diving only to cruising or design maneuvering airspeed, with a gradual pullup as soon as the airspeed is safely above stalling, can be effected with a load factor not to exceed 2 or 2.5 G's. A higher load factor should never be necessary unless recovery has been effected with the airplane's nose near or beyond the vertical attitude, or at extremely low altitudes to avoid diving into the ground.

SPINS. Since a stabilized spin is not essentially different from a stall in any element other than rotation, the same load factor considerations apply as those which apply to stall recovery. Since spin recoveries usually are effected with the nose much lower than is common in stall recoveries, higher airspeeds and consequently higher load factors are to be expected. The load factor in a proper spin recovery will usually be found to be about 2.5 G's.

The load factor during a spin will vary with the spin characteristics of each airplane but is usually found to be slightly above the 1 G of level flight. There are two reasons this is true:

1. The airspeed in a spin is very low;

usually within 2 knots of the unaccelerated stalling speeds; and

2. The airplane pivots, rather than

turns, while it is in a spin.

HIGH SPEED STALLS. The average light plane is not built to withstand the repeated application of load factors common to high speed stalls. The load factor necessary for these maneuvers produces a stress on the wings and tail structure, which does not leave a reasonable margin of safety in most light airplanes.

The only way this stall can be induced at an airspeed above normal stalling involves the imposition of an added load factor, which may be accomplished by a severe pull on the elevator control. A speed of 1.7 times stalling speed (about 102 knots in a light airplane with a stalling speed of 60 knots) will produce a load factor of 3 G's. Further, only a very narrow margin for error can be allowed for acrobatics in light airplanes. To illustrate how rapidly the load factor increases with airspeed, a high speed stall at 112 knots in the same airplane would produce a load factor of 4 G's.

CHANDELLES AND LAZY EIGHTS. It would be difficult to make a definite statement concerning load factors in these maneuvers as both involve smooth, shallow dives and pullups. The load factors incurred depend directly on the speed of the dives and the abruptness of the pullups.

Generally, the better the maneuver is performed, the less extreme will be the load factor induced. A chandelle or lazy eight, in which the pullup produces a load factor greater than 2 G's will not result in as great a gain in altitude, and in low powered airplanes it may result in a net loss of altitude.

The smoothest pullup possible, with a moderate load factor, will deliver the greatest gain in altitude in a chandelle and will result in a better overall performance in both chandelles and lazy eights. Further, it will be noted that recommended entry speed for these maneuvers is generally near the manufacturer's design maneuvering speed, thereby allowing maximum development of load factors without exceeding the load limits.

ROUGH AIR. All certificated airplanes are designed to withstand loads imposed by gusts of considerable intensity. Gust load factors increase with increasing airspeed and the strength used for design purposes usually corresponds to the highest level flight speed. In extremely rough air, as in thunderstorms or frontal conditions, it is wise to reduce the speed to the design maneuvering speed. Regardless of the speed held, there may be gusts that can produce loads which exceed the load limits.

Most airplane flight manuals now include turbulent air penetration information. Operators of modern airplanes, capable of a wide range of speeds and altitudes, are benefitted by this added feature both in comfort and safety. In this connection it is to be noted that the maximum "never exceed" placard dive speeds are determined for smooth air only. High speed dives or acrobatics involving speed above the known maneuvering speed should never be practiced in rough or turbulent air.

In summary, it must be remembered that load factors induced by intentional acrobatics, abrupt pullups from dives, high speed stalls, and gusts at high airspeeds all place added stress on the entire structure of an airplane.

Stress on the structure involves forces on any part of the airplane. There is a tendency for the uninformed to think of load factors only in terms of their effect on spars and struts. Most structural failures due to excess load factors involve rib structure within the leading and trailing edges of wings and tail group. The critical area of fabric covered airplanes is the covering about one-third of the chord aft on the top surface of the wing.

The cumulative effect of such loads over a long period

of time may tend to loosen and weaken vital parts so that actual failure

may occur later when the airplane is being operated in a normal manner.