When an airplane is flown at a high altitude, it consumes less fuel for a given airspeed than it does for the same speed at a lower altitude. In other words, the airplane is more efficient at a high altitude. In addition, bad weather and turbulence can be avoided by flying in the relatively smooth air above the storms. Airplanes which do not have pressurization and air conditioning systems are usually limited to the lower altitudes. Because of the advantages of flying at high altitudes, many modern general aviation type airplanes are being designed to operate in that environment. It is important then, that pilots transitioning to such sophisticated equipment be familiar with at least the basic operating principles.

A cabin pressurization system accomplishes several functions in providing adequate passenger comfort and safety. It maintains a cabin pressure altitude of approximately 8,000 feet at the maximum designed cruising altitude of the airplane, and prevents rapid changes of cabin altitude which may be uncomfortable or injurious to passengers and crew. In addition, the pressurization system permits a reasonably fast exchange of air from inside to outside the cabin. This is necessary to eliminate odors and to remove stale air.

Pressurization of the airplane cabin is now the accepted method of protecting persons against the effects of hypoxia. Within a pressurized cabin, people can be transported comfortably and safely for long periods of time, particularly if the cabin altitude is maintained at 8,000 feet or below, where the use of oxygen equipment is not required. However, the flight crew in this type of airplane must be aware of the danger of accidental loss of cabin pressure and must be prepared to meet such an emergency whenever it occurs.

In this typical pressurization system, the cabin, flight compartment, and baggage compartments are incorporated into a sealed unit which is capable of containing air under a pressure higher than outside atmospheric pressure. Pressurized air is pumped into this sealed fuselage by cabin superchargers which deliver a relatively constant volume of air at all altitudes up to a designed maximum. Air is released from the fuselage by a device called an outflow valve. Since the superchargers provide a constant inflow of air to the pressurized area, the outflow valve, by regulating the air exit, is the major controlling element in the pressurization system.

It is necessary to become familiar with some terms and definitions to understand the operating principles of pressurization and air conditioning systems. These are:

1. Aircraft altitude. The actual height

above sea level at which the airplane is flying.

2. Ambient temperature. The temperature

in the area immediately surrounding the airplane.

3. Ambient pressure. The pressure in

the area immediately surrounding the airplane.

4. Cabin altitude. Used to express cabin

pressure in terms of equivalent altitude above sea level.

5. Differential pressure. The difference

in pressure between the pressure acting on one side of a wall and the pressure

acting on the other side of the wall. In aircraft air conditioning and

pressurizing systems, it is the difference between cabin pressure and atmospheric

pressure.

The cabin pressure control system provides cabin pressure regulation, pressure relief, vacuum relief, and the means for selecting the desired cabin altitude in the isobaric and differential range. In addition, dumping of the cabin pressure is a function of the pressure control system. A cabin pressure regulator, an outflow valve, and a safety valve are used to accomplish these functions.

The cabin pressure regulator controls cabin pressure to a selected value in the isobaric range and limits cabin pressure to a preset differential value in the differential range. When the airplane reaches the altitude at which the difference between the pressure inside and outside the cabin is equal to the highest differential pressure for which the fuselage structure is designed and further increase in airplane altitude will result in a corresponding increase in cabin altitude. Differential control is used to prevent the maximum differential pressure, for which the fuselage was designed, from being exceeded. This differential pressure is determined by the structural strength of the cabin and often by the relationship of the cabin size to the probable areas of rupture, such as window areas and doors.

The cabin air pressure safety valve is a combination pressure relief, vacuum relief, and dump valve. The pressure relief valve prevents cabin pressure from exceeding a predetermined differential pressure above ambient pressure. The vacuum relief prevents ambient pressure from exceeding cabin pressure by allowing external air to enter the cabin when ambient pressure exceeds cabin pressure. The dump valve is actuated by the cockpit control switch. When this switch is positioned to "ram," a solenoid valve opens, causing the valve to dump cabin air to atmosphere.

The degree of pressurization and, therefore, the operating altitude of the aircraft are limited by several critical design factors. Primarily the fuselage is designed to withstand a particular maximum cabin differential pressure.

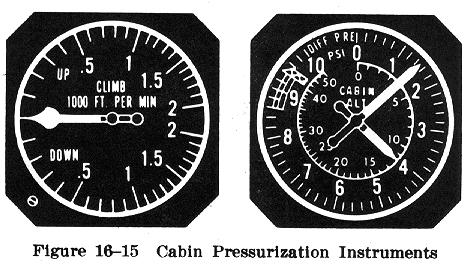

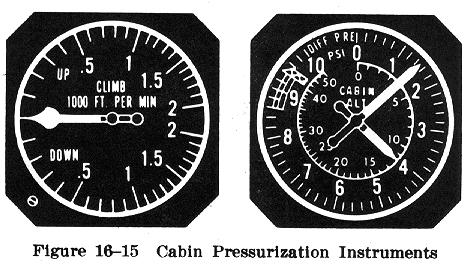

Several instruments are used in conjunction with the pressurization controller. The cabin differential pressure gauge indicates the difference between inside and outside pressure. This gauge should be monitored to assure that the cabin does not exceed the maximum allowable differential pressure. A cabin altimeter is also provided as a check on the performance of the system. In some cases, these two instruments are combined into one. A third instrument indicates the cabin rate of climb or descent. A cabin rate of climb instrument and a cabin altimeter are illustrated in Fig. 16-15.

Decompression is defined as the inability of the airplane's pressurization system to maintain its designed pressure differential. This can be caused by a malfunction in the pressurization system or structural damage to the airplane. Physiologically, decompressions fall into two categories:

1. Explosive Decompression. Explosive decompression is defined as a change in cabin pressure faster than the lungs can decompress. Therefore, it is possible that lung damage may occur. Normally, the time required to release air from the lungs where no restrictions exist, such as masks, etc., is 0.2 seconds. Most authorities consider any decompression which occurs in less than 0.5 seconds as explosive and potentially dangerous.

2. Rapid Decompression. Rapid decompression is defined as a change in cabin pressure where the lungs can decompress faster than the cabin. Therefore there is no likelihood of lung damage.

During a decompression there may be noise, and for a split second one may feel dazed. The cabin air will fill with fog, dust or flying debris. Fog occurs due to the rapid drop in temperature and the change of relative humidity. Normally, the ears clear automatically. Belching or passage of intestinal gas may occur. Air will rush from the mouth and nose due to the escape of air from the lungs, and may be noticed by some individuals.

The primary danger of decompression is hypoxia. Unless proper utilization of oxygen equipment is accomplished quickly, unconsciousness may occur in a very short time. The period of useful consciousness is considerably shortened when a person is subjected to a rapid decompression. This is due to the rapid reduction of pressure on the body. Thus, oxygen in the lungs is exhaled rapidly. This in effect reduces the partial pressure of oxygen in the blood and thus reduces the pilot's effective performance time by 1/3 to 1/4 its normal time. It is for this reason the oxygen mask should be worn on the face when flying at very high altitudes (35,000 feet or higher). It is recommended that the crewmembers select the 100% oxygen setting on the oxygen regulator at high altitude if the airplane is equipped with a demand or pressure demand oxygen system.

Another hazard is that of being tossed or blown out of

the airplane if near an opening. For this reason, individuals near such

openings should wear safety harnesses or seatbelts at all times when the

airplane is pressurized and they are seated.

Still another potential hazard on high altitude decompressions

is the possibility of evolved gas decompression sicknesses. Exposure to

windblast and extremely cold temperatures are other hazards one might have

to face.

Rapid descent from altitude is indicated if these problems

are to be minimized. This descent is briefly discussed in Chapter 11. Automatic

visual and aural warning systems are included in the equipment of all pressurized

airplanes so that slow decompressions will not occur and overwhelm the

crew before they are detected.