There are three basic types of dc motors: (1) Series motors, (2) shunt motors, and (3) compound motors. They differ largely in the method in which their field and armature coils are connected.

Series DC Motor

In the series motor, the field windings, consisting of a relatively few turns of heavy wire, are connected in series with the armature winding. Both a diagrammatic and a schematic illustration of a series motor is shown in figure 9-75. The same current flowing through the field winding also flows through the armature winding. Any increase in current, therefore, strengthens the magnetism of both the field and the armature.

Because of the low resistance in the windings, the series motor is able to draw a large current in starting. This starting current, in passing through both the field and armature windings, produces a high starting torque, which is the series motor's principal advantage.

The speed of a series motor is dependent upon the load. Any change in load is accompanied by a substantial change in speed. A series motor will run at high speed when it has a light load and at low speed with a heavy load. If the load is removed entirely, the motor may operate at such a high speed that the armature will fly apart. If high starting torque is needed under heavy load conditions, series motors have many applications. Series motors are often used in aircraft as engine starters and for raising and lowering landing gears, cowl flaps, and wing flaps.

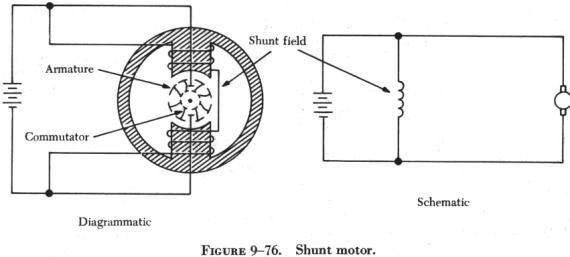

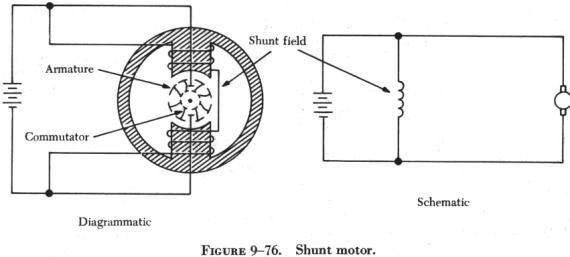

Shunt DC Motor

In the shunt motor the field winding is connected in parallel or in shunt with the armature winding. (See figure 9-76) The resistance in the field winding is high. Since the field winding is connected directly across the power supply, the current through the field is constant. The field current does not vary with motor speed, as in the series motor and, therefore, the torque of the shunt motor will vary only with the current through the armature. The torque developed at starting is less than that developed by a series motor of equal size.

The speed of the shunt motor varies very little with changes in load. When all load is removed, it assumes a speed slightly higher than the loaded speed. This motor is particularly suitable for use when constant speed is desired and when high starting torque is not needed.

Compound DC Motor

The compound motor is a combination of the series and shunt motors. There are two windings in the field: a shunt winding and a series winding. A schematic of a compound motor is shown in figure 9-77. The shunt winding is composed of many turns of fine wire and is connected in parallel with the armature winding. The series winding consists of a few turns of large wire and is connected in series with the armature winding. The starting torque is higher than in the shunt motor but lower than in the series motor. Variation of speed with load is less than in a series wound motor but greater than in a shunt motor. The compound motor is used whenever the combined characteristics of the series and shunt motors are desired.

Like the compound generator, the compound motor has both series and shunt field windings. The series winding may either aid the shunt wind (cumulative compound) or oppose the shunt winding (differential compound).

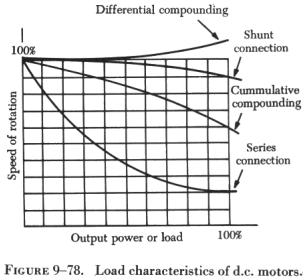

The starting and load characteristics

of the cumulative compound motor are somewhere between those of the series

and those of the shunt motor.

| Because of the series

field, the cumulative compound motor has a higher starting torque than

a shunt motor. Cumulative compound motors are used in driving machines

which are subject to sudden changes in load. They are also used where a

high starting torque is desired, but a series motor cannot be used easily.

In the differential compound motor, an increase in load creates an increase in current and a decrease in total flux in this type of motor. These two tend to offset each other and the result is a practically constant speed. However, since an increase in load tends to decrease the field strength, the speed characteristic becomes unstable. Rarely is this type of motor used in aircraft systems. A graph of the variation in speed with changes of load of the various types of dc motors is shown in figure 9-78. |

|

Counter E. M. F.

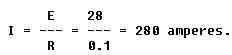

The armature resistance of a small, 28 volt dc motor is extremely low, about 0.1 ohm. When the armature is connected across the 28 volt source, current through the armature will apparently be

This high valve of current flow is not only impracticable but also unreasonable, especially when the current drain, during normal operation of a motor, is found to be about 4 amperes. This is because the current through a motor armature during operation is determined by more factors than ohmic resistance.

When the armature in a motor rotates in a magnetic field, a voltage is induced in its windings. This voltage is called the back or counter e.m.f. (electromotive force) and is opposite in direction to the voltage applied to the motor from the external source.

Counter e.m.f. opposes the current which causes the armature to rotate. The current flowing through the armature, therefore, decreases as the counter e.m.f. increases. The faster the armature rotates, the greater the counter e.m.f. For this reason, a motor connected to a battery may draw a fairly high current on starting, but as the armature speed increases, the current flowing through the armature decreases. At rated speed, the counter e.m.f. may be only a few volts less than the battery voltage. Then, if the load on the motor is increased, the motor will slow down, less counter e.m.f. will be generated, and the current drawn from the external source will increase. In a shunt motor, the counter e.m.f. affects only the current in the armature, since the field is connected in parallel across the power source. As the motor slows down and the counter e.m.f. decreases, more current flows through the armature, but the magnetism in the field is unchanged. When the series motor slows down, the counter e.m.f. decreases and more current flows through the field and the armature, thereby strengthening their magnetic fields. Because of these characteristics, it is more difficult to stall a series motor than a shunt motor.

Types of Duty

Electric motors are called upon to operate under various conditions. Some motors are used for intermittent operation; others operate continuously. Motors built for intermittent duty can be operated for short periods only and, then, must be allowed to cool before being operated again. If such a motor is operated for long periods under full load, the motor will be overheated. Motors built for continuous duty may be operated at rated power for long periods.

Reversing Motor Direction

By reversing the direction of current

flow in either the armature or the field windings, the direction of a motor's

rotation may be reversed. This will reverse the magnetism of either the

armature or the magnetic field in which the armature rotates. If the wires

connecting the motor to an external source are interchanged, the direction

of rotation will not be reversed, since changing these wires reverses the

magnetism of both field and armature and leaves the torque in the same

direction as before.

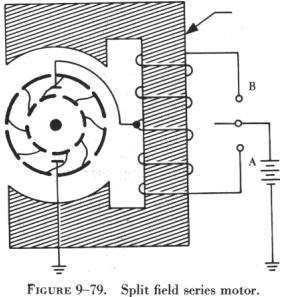

| One method for reversing direction of rotation employs two field windings wound in opposite directions on the same pole. This type of motor is called a split field motor. Figure 9-79 shows a series motor with a split field winding. The single pole, double throw switch makes it possible to direct current through either of the two windings. When the switch is placed in the lower position, current flows through the lower field winding, creating a north pole at the lower field winding and at the lower pole piece, and a south pole at the upper pole piece. When the switch is placed in the upper position, current flows through the upper field winding, the magnetism of the field is reversed, and the armature rotates in the opposite direction. Some split field motors are built with two separate field windings wound on alternate poles. The armature in such a motor, a four pole reversible motor, rotates in one direction when current flows through the windings of one set of opposite pole pieces, and in the opposite direction when current flows through the other set of windings. |

|

|

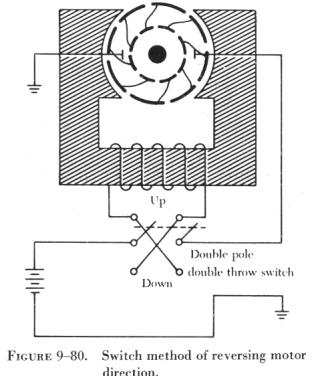

Another method of direction reversal,

called the switch method, employs a double pole, double throw switch which

changes the direction of current flow in either the armature or the field.

In the illustration of the switch method shown in figure 9-80, current

direction may be reversed through the field but not through the armature.

When the switch is thrown to the "up" position, current flows through the

field winding to establish a north pole at the right side of the motor

and a south pole at the left side of the motor. When the switch is thrown

to the "down" position, this polarity is reversed and the armature rotates

in the opposite direction.

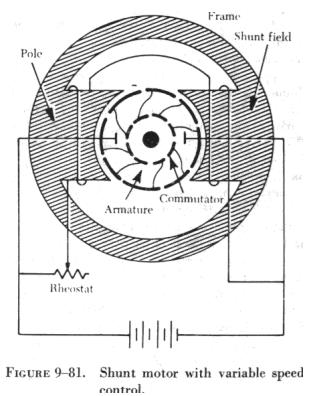

Motor Speed Motor speed can be controlled by varying the current in the field windings. When the amount of current flowing through the field windings is increased, the field strength increases, but the motor slows down since a greater amount of counter e.m.f. is generated in the armature windings. When the field current is decreased, the field strength decreases, and the motor speeds up because the counter e.m.f. is reduced. A motor in which speed can be controlled is called a variable speed motor. It may be either a shunt or series motor. |

| In the shunt motor, speed is controlled

by a rheostat in series with the field windings (figure 9-81). The speed

depends on the amount of current which flows through the rheostat to the

field windings. To increase the motor speed, the resistance in the rheostat

is increased, which decreases the field current. As a result, there is

a decrease in the strength of the magnetic field and in the counter e.m.f.

This momentarily increases the armature current and the torque. The motor

will then automatically speed up until the counter e.m.f. increases and

causes the armature current to decrease to its former value. When this

occurs, the motor will operate at a higher fixed speed than before.

To decrease the motor speed, the resistance of the rheostat is decreased. More current flows through the field windings and increases the strength of the field; then, the counter e.m.f. increases momentarily and decreases the armature current. As a result, the torque decreases and the motor slows down until the counter e.m.f. decreases to its former value; then the motor operates at a lower fixed speed than before. |

|

In the series motor (figure 9-82), the rheostat speed control is connected either in parallel or in series with the motor field, or in parallel with the armature. When the rheostat is set for maximum resistance, the motor speed is increased in the parallel armature connection by a decrease in current. When the rheostat resistance is maximum in the series connection, motor speed is reduced by a reduction in voltage across the motor. For above normal speed operation, the rheostat is in parallel with the series field. Part of the series field current is bypassed and the motor speeds up.

Energy Losses in DC Motors

Losses occur when electrical energy is converted to mechanical energy (in the motor), or mechanical energy is converted to electrical energy (in the generator). For the machine to be efficient, these losses must be kept to a minimum. Some losses are electrical, others are mechanical. Electrical losses are classified as copper losses and iron losses; mechanical losses occur in overcoming the friction of various parts of the machine.

Copper losses occur when electrons are forced through the copper windings of the armature and the field. These losses are proportional to the square of the current. They are sometimes called I2R losses, since they are due to the power dissipated in the form of heat in the resistance of the field and armature windings.

Iron losses are subdivided in hysteresis and eddy current losses. Hysteresis losses are caused by the armature revolving in an alternating magnetic field. It, therefore, becomes magnetized first in one direction and then in the other. The residual magnetism of the iron or steel of which the armature is made causes these losses. Since the field magnets are always magnetized in one direction (dc field), they have no hysteresis losses.

Eddy current losses occur because the iron core of the armature is a conductor revolving in a magnetic field. This sets up an e.m.f. across portions of the core, causing currents to flow within the core. These currents heat the core and, if they become excessive, may damage the windings. As far as the output is concerned, the power consumed by eddy currents is a loss. To reduce eddy currents to a minimum, a laminated core usually is used. A laminated core is made of thin sheets of iron electrically insulated from each other. The insulation between laminations reduces eddy currents, because it is "transverse" to the direction in which these currents tend to flow. However, it has no effect on the magnetic circuit. The thinner the laminations, the more effectively this method reduces eddy current losses.

Inspection and Maintenance of DC Motors

Use the following procedures to make inspection and maintenance checks:

1. Check the operation of the unit driven by the motor in accordance with the instructions covering the specific installation.

2. Check all wiring, connections, terminals, fuses, and switches for general condition and security.

3. Keep motors clean and mounting bolts tight.

4. Check brushes for condition, length, and spring tension. Minimum brush lengths, correct spring tension, and procedures for replacing brushes are given in the applicable manufacturer's instructions.

5. Inspect commutator for cleanness, pitting, scoring, roughness, corrosion or burning. Check for high mica (if the copper wears down below the mica, the mica will insulate the brushes from the commutator). Clean dirty commutators with a cloth moistened with the recommended cleaning solvent. Polish rough or corroded commutators with fine sandpaper (000 or finer) and blow out with compressed air. Never use emery paper since it contains metallic particles which may cause shorts. Replace the motor if the commutator is burned, badly pitted, grooved, or worn to the extent that the mica insulation is flush with the commutator surface.

6. Inspect all exposed wiring for evidence of overheating. Replace the motor if the insulation on leads or windings is burned, cracked, or brittle.

7. Lubricate only if called for by the manufacturer's instructions covering the motor. Most motors used in today's airplanes require no lubrication between overhauls.

8. Adjust and lubricate the gearbox, or unit which the motor drives, in accordance with the applicable manufacturer's instructions covering the unit.

When trouble develops in a dc motor system, check first to determine the source of the trouble. Replace the motor only when the trouble is due to a defect in the motor itself. In most cases, the failure of a motor to operate is caused by a defect in the external electrical circuit, or by mechanical failure in the mechanism driven by the motor.

Check the external electrical circuit for loose or dirty connections and for improper connection of wiring. Look for open circuits, grounds, and shorts by following the applicable manufacturer's circuit testing procedure. If the fuse is not blown, failure of the motor to operate is usually due to an open circuit. A blown fuse usually indicates an accidental ground or short circuit. The chattering of the relay switch which controls the motor is usually caused by a low battery. When the battery is low, the open circuit voltage of the battery is sufficient to close the relay, but with the heavy current draw of the motor, the voltage drops below the level required to hold the relay closed. When the relay opens, the voltage in the battery increases enough to close the relay again. This cycle repeats and causes chattering, which is very harmful to the relay switch, due to the heavy current causing an arc which will burn the contacts.

Check the unit driven by the motor for failure of the unit or drive mechanism. If the motor has failed as a result of a failure in the driven unit, the fault must be corrected before installing a new motor.

If it has been determined that the fault is in the motor itself (by checking for correct voltage at the motor terminals and for failure of the driven unit), inspect the commutator and brushes. A dirty commutator or defective or binding brushes may result in poor contact between brushes and commutator. Clean the commutator, brushes, and brush holders with a cloth moistened with the recommended cleaning solvent. If brushes are damaged or worn to the specified minimum length, install new brushes in accordance with the applicable manufacturer's instructions covering the motor. If the motor still fails to operate, replace it with a serviceable motor.