AIRCRAFTFIRE

AIRCRAFT FIRE EXTINGUISHERS

Fire is one of the most dangerous threats to aircraft - either in flight

or on the ground. Airborne fixed, powerplant and airframe, detection and

extinguishing systems are designed and installed by the manufacturer in

compliance with applicable FARs. The requirement for portable fire extinguishers

installed in the crew and passenger compartment says, the extinguisher

must be approved, must be appropriate for the kind of fire likely to occur

and must minimize the hazard of toxic gases.

The National Fire Protection Association (NFPA) Standard #408, Aircraft

Hand Fire Extinguishers, suggests the type, capacity, location and quantity

of hand fire extinguishers for the protection of aircraft compartments

occupied by passengers and crew. This standard suggests carbon dioxide

and water (water solution) as the extinguishing media for hand type extinguishers.

Both type extinguishers are suggested for use in the passenger compartment,

the number of units being regulated by the number of passengers carried.

Carbon dioxide is suggested for the crew compartment. A halogenated hydrocarbon

extinguishing agent (Halon 1211 or Halon 1301) having an Underwriter's

Laboratory toxicity rating of 5 or higher may be substituted for the carbon

dioxide, if there is sufficient free air volume in the immediate area to

prevent serious irritating effects on the occupants.

The following extinguishing agents are not recommended for aircraft

use:

1. Dry chemical extinguishers are very effective in Class B and C fires

but they leave a residual dust or powder. This obstructs vision, is difficult

to clean up and causes damage to electronic equipment.

2. Carbon tetrachloride is no longer approved as a fire extinguishing

agent. It produces a poisonous gas (phosgene) when in contact with hot

metals. Soda acid and foam, these are toxic to a degree and can be corrosive

to adjacent materials.

3. Methyl bromide is more toxic than CO2 and cannot be used in confined

areas. It is also very corrosive to aluminum alloy, magnesium and zinc.

4. Chlorobromomethane, although an effective extinguishing agent, is

toxic.

| Extinguishers

The common aerosol can type extinguishers are definitely not acceptable

as airborne hand type extinguishers. In one instance, an aerosol type foam

extinguisher located in the pilot's seat back pocket exploded and tore

the upholstery from the seat. The interior of the aircraft was damaged

by the foam. This occurred when the aircraft was on the ground and the

outside temperature was 90° F. In addition to the danger from explosion,

the size is inadequate to combat even the smallest fire. In another instance,

a dry chemical extinguisher was mounted near a heater vent on the floor.

For an unknown reason, the position of the unit was reversed. This placed

the extinguisher directly in front of the heater vent. During flight, with

the heater in operation, the extinguisher became overheated and exploded

filling the compartment with dry chemical powder. The proximity of heater

vents should be considered when selecting a location for a hand fire extinguisher. |

|

|

Additional information relative to airborne hand fire extinguishers

may be obtained from the local FAA District Office and from the National

Fire Protection Association, 470 Atlantic Ave., Boston, MA 02210.

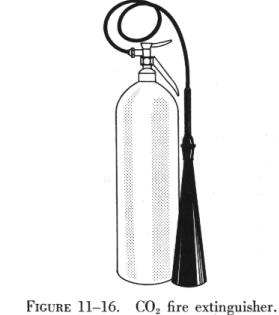

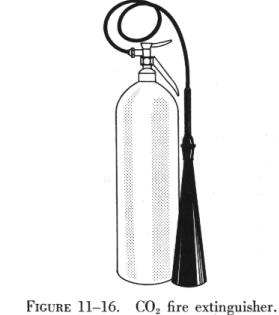

Ground Type Extinguishers - Hand Type

The selection of a fire extinguisher for ground installation, shop,

fueling station, etc., is not restricted as it is for airborne installations.

The range of selection for agent and type extinguishers is shown in figure

11-11. (See figure 11-16 and figure 11-17).

Methods of Extinguisher Operation. The methods of operation of extinguishers

are most conveniently arranged by grouping extinguishers according to their

expelling means. Six methods are in common use. |

Selfgenerating - actuation causes gases to be generated that

provide expellent energy.

Selfexpelling - the agents have sufficient vapor pressure at

normal operating temperatures to expel themselves.

Gas cartridge or cylinder - expellent gas is confined in a separate

pressure vessel until an operator releases it to pressurize the extinguisher

shell.

Stored pressure - the extinguishing material and expellent gas

are kept in a single container.

Mechanically pumped - the operator provides expelling energy

by means of a pump and the vessel containing the agent is not pressurized.

Hand propelled - the material is applied with scoop, pail, or

bucket.

Several different extinguishing materials are handled by each of these

expelling means.

Discontinued Fire Extinguishers (see figure

11-14 and figure 11-15)

There are still in use today several million fire extinguishers of a

design no longer manufactured. These are the 1 1/2, 2 1/2 and 5 gallon

"invert to use" liquid extinguishers. The last of this type were manufactured

in the 2 1/2 gallon size. The agents used in these extinguishers are:

1. Soda-acid.

2. Foam.

3. Water cartridge.

4. Loaded stream cartridge.

The reasons which influenced the decision to discontinue manufacturing

these extinguishers are:

1. Invert to use - difficult and unorthodox method of activation.

2. Limited to the types of fires for which they are suitable. Mostly

Class "A" fires, very limited application of foam on Class "B" fires.

3. None approved for electrical fires.

4. Effective on only minimal size fires.

5. The container does not meet current pressure vessel standards. This

is the most significant of all.

Comparison of Safety Factors

Discontinued types of extinguishers use a shell rated at either 350

or 500 psi. However, when these extinguishers are inverted to operate,

the pressures generated often are unpredictable, totally unlike the pressures

in other extinguisher designs. Pressures may range from 100 to 300 psi

for soda acid extinguishers and from 100 to 350 psi for the foam extinguishers.