AIRCRAFTFUELING

AIRCRAFT FUELING

| Strict fire precautions must be adhered to during the fueling

process. Smoking is not permitted in or around an aircraft during fueling.

Also, open flames such as oil lanterns, candles, or matches are prohibited.

Exposed electric switches, sliprings or commutators, dynamos or motors,

spark producing electrical equipment, or any burning material must not

be permitted within 100 feet of an aircraft being fueled or defueled. No

lights other than approved explosion proof lights are permitted within

100 feet of these operations, and no light of any sort may be placed where

it can come in contact with spilled fuel. Warning signs should be posted

as a precautionary measure.

All aircraft fuels or other combustible liquids accidentally spilled

should be immediately removed by washing with water or covered with a foam

blanket to prevent ignition, or neutralized by other means. The proper

fire authorities must be notified if necessary.

If indications of underground leakage of combustible liquids are discovered,

areas must be guarded by appropriate means, and the proper fire authorities

must be notified immediately. |

|

|

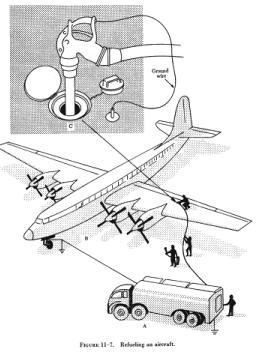

figure 11-7

|

It is recommended that aircraft fuel tanks be filled before storing aircraft

in hangars, since this leaves no space for explosive vapors to form. This

practice is also recommended after each flight to prevent water condensation

in fuel tanks.

The fuel tanks should not be filled completely to the top when aircraft

are stored in hangars, especially if the outside temperature is cooler

than the inside temperature. If it is warmer inside the hangar than outside,

fuel in the tanks expands and causes overflow through the fuel tank's venting

system, creating a fire hazard. Nonspark tools must be used when working

on any part of a system or unit designed for storing or handling combustible

liquids.

Use of leaky tanks or fuel lines is not permitted. Repairs must be made

on discovery, with due regard to the hazard involved.

All fuel is filtered and passes through water separating equipment at

the tank farm when it is delivered to the mobile refueler; or in the case

of island-type refueling stations, as it leaves the supply connections.

The mobile refueler also passes the fuel through a system of filters and

water separating equipment before its delivery to the aircraft. These filters

and separators are usually checked in the morning for evidence of dirt

and water, and each time thereafter that the mobile refueler is reloaded.

When the mobile refueler is loaded, it must sit at least 15 minutes and

then have the sumps checked for water before any aircraft are refueled

from it.

When using fuel which has been stored in cans or barrels, it must be

run through a strainer funnel before being put into aircraft. This practice

is necessary as condensation and rust develop inside cans and barrels.

If a chamois is used to filter the fuel, an increase in the static electricity

hazard results from the passage of gasoline through the material. The chamois

must be grounded and remain grounded until all gasoline has drained through

the filter. This can be done by contact with a supporting metal screen

which is positively grounded. Never use a plastic funnel, bucket, or similar

nonconductive container when servicing from storage cans or barrels.

Aircraft should be fueled in a safe place. Do not fuel or defuel an

aircraft in a hangar or other enclosed space except in case of an emergency.

Aircraft should be free from fire hazards, and have engine switches off

and chocks placed under the wheels prior to fueling or defueling.

A person who functions as a fireguard with a CO2 extinguisher or other

firefighting equipment should possess a thorough knowledge of all fuel

servicing hazards. He should guard against breathing hydrocarbon vapors,

which may cause sickness or dizziness, or may even be fatal. Adequate ventilating

measures to prevent the accumulation of fumes should be provided.

Because of its high lead content, fuel should not be allowed to come

in contact with clothes, skin, or eyes. Fuel saturated clothing should

be removed as soon as possible and the parts of the body exposed to the

fuel washed thoroughly with soap and water. Wearing clothing saturated

with fuel creates a dangerous fire hazard, and painful blisters (similar

to those caused by fire burns) may result from direct contact with fuel.

If fuel enters the eyes, medical attention should be sought immediately.

Refueling Crew Duties

When an aircraft is to be overwing fueled by truck, it should be located

on the apron or a dispersal site, and should not be in the vicinity of

possible sources of fuel vapor ignition. Consideration must be given to

the direction of the wind so that fuel vapors are not carried toward a

source of ignition.

The tank truck should be driven to a point as distant from the aircraft

as the length of hose permits, and preferably to the windward (upwind)

side of the aircraft. It must be parked parallel to or heading away from

the wing, or in such a position that it may be driven away quickly in the

event of fire (A of figure 11-7). As soon as the fueling operation has

been completed, the truck should be removed from the aircraft's vicinity.

The truck fuel tank covers should be kept closed except when a tank is

actually being loaded.

Ideally, refueling crews for large aircraft would possibly involve four

men. One person stands by with the firefighting equipment; another stays

with the truck; the third man handles the fuel hose on the ground; and

the fourth man handles the fueling hose at the aircraft and fills the tanks

(A and B of figure 11-7).

Care should be taken to identify the aviation fuel and lubricating oil

dispensed from each refueling unit before beginning the actual servicing.

Aviation technicians should be familiar with the various grades and the

aircraft's gasoline requirements so that the appropriate fuel is used.

A check should also be made to see that all radio equipment and electrical

switches not needed for the fueling operation are turned off, and nonessential

outside electrical sources are not connected to the aircraft. A member

of the crew then makes sure that both the aircraft and the truck are properly

grounded to prevent sparks from static electricity.

Fueling Operations

In the overwing fueling of large aircraft, the man with the CO2 bottle

stands close to the aircraft to be refueled. The fuel hose handler on the

truck unreels the hose and passes it up to the man on the aircraft who

is to do the fueling. Care should be taken in bringing the hose nozzle

up to the filler neck of the fuel tank to avoid excessive marring of the

aircraft finish. Attached to the nozzle is a ground wire which is plugged

into the receptacle adjacent to the fuel tank to be filled. Another type

of ground wire commonly used terminates in an alligator clip connected

to a grounding post. This connection is made before the fuel tank cap is

removed from the filler neck. This serves as a continuous ground connection

for the fuel nozzle (C of figure 11-7). The fuel truck has two ground wires;

one is connected to a suitable ground on the apron (A of figure 11-7),

and the other is connected to the aircraft (A and B figure 11-7). The aircraft

should also be grounded to the apron.

This grounding arrangement may take other forms. In many cases, the

fuel truck is grounded by a metal chain that is dragged behind the truck;

the aircraft is grounded by a carbon strip embedded in the tires; and the

aircraft and fuel truck are held at a common electrical potential by a

conducting wire encircling the fuel hose from nozzle to tank fitting. All

this is to prevent a spark from static electricity that may be created

as the fuel flows through the fuel hose into the aircraft's fuel tank.

| The fueling of light aircraft involves fewer problems.

While the fueler's responsibilities are still the same, it is usually a

one or two man operation. The danger of marring the aircraft finish is

minimized since the height and location of the fuel tanks usually permit

easy accessibility to the filler neck. In addition, small aircraft can

be easily pushed by hand to a fueling position near a fuel truck or a fueling

island. Figure 11-8 shows a small aircraft being fueled.

When the fuel tank is nearly full, the rate of fuel flow should be reduced

for topping off the tank; that is, the tank should be slowly filled to

the top without spilling fuel on the wing or ground. The filler cap is

replaced on that tank, the ground wire plug removed from its receptacle,

and then the man handling the fuel nozzle takes the hose and moves on to

the next tank to be filled. This procedure is followed at each tank until

the aircraft is completely refueled. Then the ground wires are disconnected

from the aircraft, and the hose is rewound onto the hose reel in the truck.

During this operation the hose or nozzle should not be allowed to drop

to the ground. |

|

Pressure Fueling

Pressure fueling is used on many late model aircraft. This fueling process,

sometimes referred to as single point or underwing fueling, greatly reduces

the time required to service large aircraft. There are also other advantages

in the pressure fueling process. It eliminates aircraft skin damage and

hazards to personnel and reduces the chances for fuel contamination. Pressure

fueling also reduces the chance of static electricity igniting fuel vapors.

Because of the limited fuel tank area, there are fewer advantages of

a pressure fueling system in light aircraft. Thus, they are usually incorporated

only in medium size executive jets and large military or commercial transport

aircraft.

Most pressure fueling systems consist of a pressure fueling hose and

a panel of controls and gauges that permit one man to fuel or defuel any

or all fuel tanks of an aircraft. A single point fueling system is usually

designed so that an in the wing fueling manifold is accessible near a wingtip

or under the wing near the wing root. The valves connecting the various

tanks to the main fueling manifold are usually actuated in response to

fuel pressure signals.

Fueling and defueling procedures are normally placarded on the fueling

control panel access door. The fueling operator should possess a thorough

knowledge of the aircraft fuel system to recognize malfunction symptoms.

Since the design of pressure fueling systems varies somewhat with each

type of aircraft, the fueling operator should consult the manufacturer's

instructions for detailed procedures.

Due to varying procedures in defueling aircraft, it is important to

consult the applicable manufacturer's maintenance instructions.