AIRCRAFTTIEDOWN

AIRCRAFT TIEDOWN

| Aircraft tiedown is a very important part of aircraft ground

handling. The type of tiedown will be determined by the prevailing weather

conditions. In normal weather a limited or normal tiedown procedure is

used; but when storm conditions are anticipated, a heavy weather or storm

condition tiedown procedure should be employed.

Normal Tiedown Procedure

Small aircraft should be tied down after each flight to preclude damage

from sudden storms. The direction in which aircraft are to be parked and

tied down will be determined by prevailing or forecast wind direction.

Aircraft should be headed, as nearly as possible, into the wind, depending

on the locations of the fixed, parking area tiedown points. Spacing of

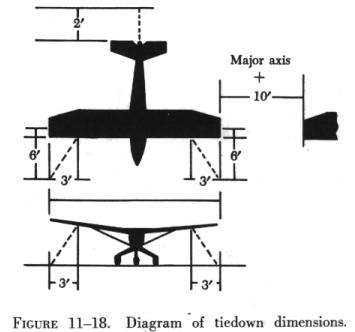

tiedowns should allow for ample wingtip clearance (figure 11-18). After

the aircraft is properly located, lock the nosewheel or the tailwheel in

the fore and aft position. |

|

Tiedown Anchors

All aircraft parking areas should be equipped for three point tiedowns.

This is facilitated at most airports by use of tiedown anchors installed

in concrete parking areas. Tiedown anchors, sometimes called "pad eyes,"

are ringlike fittings installed when the parking area is poured. They are

normally set flush with the surface of the concrete or no more than one

inch above it. There are several types of tiedown anchors in use. The type

selected is usually determined by the material used in aircraft parking

areas, since it may be a concrete paved surface, a bituminous paved surface,

or an unpaved turf area.

Location of tiedowns is usually indicated by some means such as white

or yellow paint markings or by surrounding the tiedown anchor with crushed

stone.

Tiedown anchors for small single engine aircraft should provide a minimum

holding power (strength) of approximately 3,000 pounds each. Although this

minimum can be achieved when stake driven tiedowns are used in dry or turfed

areas, such stakes will almost invariably pull out when the ground becomes

soaked from torrential rains which accompany hurricanes and some thunderstorms.

Tiedown Ropes

Tiedown ropes capable of resisting a pull of approximately 3,000 pounds

should be used to secure light aircraft. Cable or chain tiedown is usually

preferred for tying down large aircraft.

Manila ropes should be inspected periodically for mildew and rot. Nylon

or Dacron tiedown ropes are preferable to manila rope. The objection to

manila rope is that it shrinks when wet, is subject to mildew or rot, and

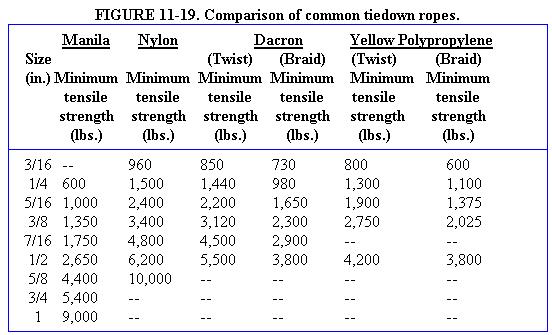

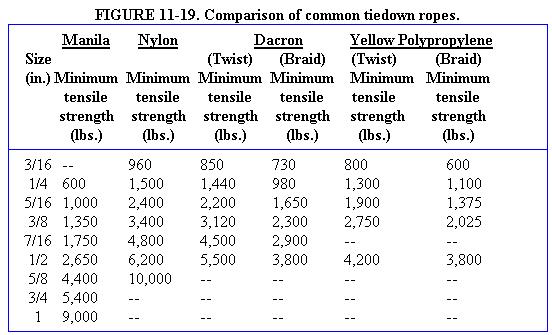

has considerably less tensile strength than either nylon or Dacron. Various

types of commonly used tiedown rope are compared in figure 11-19.

Tiedown Cable

Tiedown cables are often used to secure aircraft, especially in the

case of large aircraft. Most cable-type tiedowns are accomplished with

some form of tiedown reel designed for rapid and reliable securing of all

types of aircraft. figure 11-20 illustrates the

operation of a typical cable tiedown reel.

In A of figure 11-20 the cable is released by

depressing the release lever to provide cable slack. One end of the cable

is then attached to the aircraft tiedown ring and the other end to a tiedown

anchor. The starwheel on the reel (B of figure 11-20)

is then turned clockwise to remove excess slack from the cable. The locking

handle is then secured to the bar when the cable has been adjusted for

the desired tautness (C of figure 11-20). Finally,

as shown in D of figure 11-20, the locking cam

is secured to complete the tiedown procedure.

Tiedown Chains

The chain-type tiedown sometimes is used as a better and stronger tiedown

to secure the heaviest aircraft. This tiedown assembly is composed of an

all metal quick release mechanism, a tensioning device, and a length of

chain with hooks (figure 11-21).