|

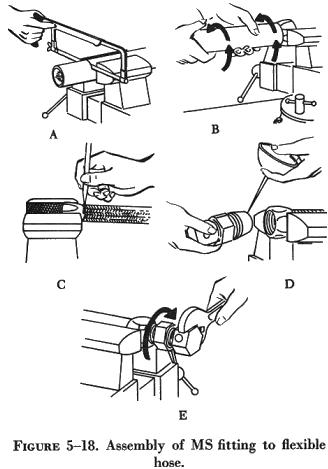

To make a hose assembly, select the proper size hose and end fittings.

Cut the hose to the correct length using a fine tooth hacksaw. Place the

socket in a vise. Screw the hose into the socket counterclockwise until

the hose bottoms on the shoulder of the socket (figure 5-18); then back

off one-quarter turn. Lubricate inside of hose and nipple threads liberally.

Mark the hose position around the hose at the rear of the socket using

a grease pencil or painted line. Insert the nipple into the nut and tighten

the nipple and nut on the assembly tool. If an assembly tool is not available,

a mating AN815 adapter may be used. Using a wrench on the assembly tool,

screw the nipple into the socket and hose. A 1/32 to 1/16 inch clearance

between the nut and sleeve is required so that the nut will swivel freely

when the assembly tool is removed. After assembly, always make sure all

foreign matter is removed from inside the hose by blowing out with compressed

air.

Proof-test After Assembly

All flexible hose must be proof-tested after assembly by plugging or

capping one end of the hose and applying pressure to the inside of the

hose assembly. The proof-test medium may be a liquid or a gas. For example,

hydraulic, fuel, and oil lines are generally tested using hydraulic oil

or water, whereas air or instrument lines are tested with dry, oil free

air or nitrogen. When testing with a liquid, all trapped air is bled from

the assembly prior to tightening the cap or plug. Hose tests, using a gas,

are conducted underwater. In all cases follow the hose manufacturer's instructions

for proof-test pressure and fluid to be used when testing a specific hose

assembly. |