|

|

||

| CHAPTER 4. Powerplants

Reciprocating Engines WSC aircraft are designed with reciprocating engines. [Figures 4-1 through 4-3] Two common means of classifying reciprocating engines are the:

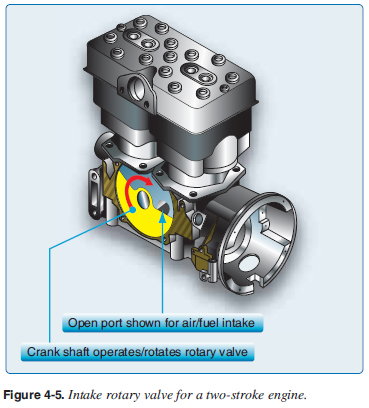

Refer to the Pilot’s Handbook of Aeronautical Knowledge for a comprehensive review of how reciprocating four-stroke engines operate. Two-Stroke Engines Two-stroke engines are commonly used in WSC aircraft. Twostroke aviation engines evolved from two-stroke snowmobile and watercraft engines, the difference being that an aircraft engine is optimized for reliability with dual ignition often installed for each cylinder. Two-stroke engines are popular because they have fewer components than four-stroke engines which makes them less expensive to manufacture and lighter, thus increasing the power-to-weight ratio. Two-stroke engines require that oil be mixed into the fuel to lubricate the engine, instead of being held in a sump and requiring a separate pressurized recirculating system like that of a four-stroke engine. Details on two-stroke oil mixing are covered in the lubrication section. One stroke as the piston moves up is intake and compression, while the second stroke as the piston moves down is power and exhaust. The two-stroke engine performs the same functions as a four-stroke engine in half the number of strokes. A wide range of valve systems are found on two-stroke engines for the purpose of opening and closing ports in the cylinder to let fuel in and exhaust out at the proper time. This is similar to the intake and exhaust valves on a four-stroke engine. One-way pressure valves, called spring, reed, or poppet valves, open when the pressure drops within the crankcase, pulling the fuel from the carburetor into the crankcase. [Figure 4-4]  Mechanical rotary valves are driven off the engine, rotate to provide an opening at the precise time, and can be on the intake and exhaust ports. [Figure 4-5]  Piston porting does not use any valves. The fuel inlet port is opened and closed by the piston position as it moves up and down in the cylinder. This is called a “piston ported inlet” and is used in the two-stroke process description that follows. |

| ©AvStop Online Magazine Contact Us Return To Books |