|

|

||

| CHAPTER 5. Prefl ight and Ground Operations

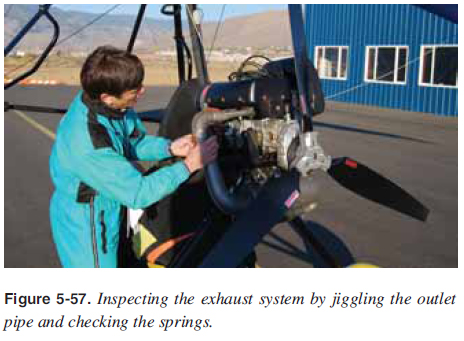

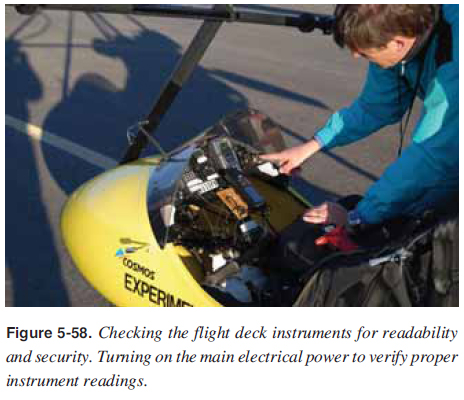

Cooling Systems Ensure there is clear airfl ow for any cooling system fan or radiator. Ensure no insects or birds created an obstruction to the airfl ow for the engine cooling system. Air cooledórotate the propeller and ensure that the cooling fan rotates also. Water cooledócheck the coolant level to ensure there is cooling fl uid in the system. Four stroke with additional oil coolersóensure the oil cooler has clear airfl ow and that nothing is blocking it. Exhaust Systems Inspect exhaust attachment to engine, and EGT senders. Slightly jiggle the exhaust system to inspect the springs holding it together. All springs must be secure. Inspect the condition of exhaust system for cracks and attachment security. [Figure 5-57]  Propeller Gearbox Rotate the propeller in the proper direction only and inspect blades for cracks or nicks. Listen and feel for smooth operation and engine compression while rotating the propeller. Inspect propeller attachment to the gearbox and the gearbox attachment to the engine. Throttle System Check all throttle controls for smooth operation and proper travel and locking. Also check choke and/or primer system for proper operation and travel. Flight Deck Inspection The following should be performed for a flight deck inspection:

Fuel Overall, particular attention should be paid to the fuel quantity, type/grade, and quality. Modern WSC two- and four-stroke engines are designed to use auto gas with various octane ratings as specifi ed by the manufacturer for different models. If auto gas is stored for more than 3 weeks, octane value may fall below the recommended rating. In this situation, it is best to drain the gas and use fresh gas. For engines designed for auto gas, aviation gasoline (AVGAS) 100LL can be mixed and used on a limited basis but the lead in this is not good for the engine and additional precautions/procedures should be researched for the particular make/model of engine for primary use. Always use a higher grade/octane of fuel rather than a lower grade, or detonation will severely damage the engine in a very short period of time. Check the aircraft operation manual and the engine manual for the type of fuel to use. When attempting to fuel for maximum capacity, remember that many fuel tanks are very sensitive to attitude. Fill the aircraft on a level surface and check to ensure the amount of fuel in the tanks is adequate for the planned fl ight plus 30 minutes of reserve. Check the level in the fuel tank plus the panel-mounted gauge, if so equipped. To transport gasoline, clear gas cans are preferable because the fuel is visible through the container and allows a pilot to look at the container for fuel level. [Figure 5-59]  An important step in any prefl ight is to check for water and other sediment contamination. Avgas is more probable to have water in the fuel tanks because auto gas typically has alcohol in it to boost the octane. Alcohol absorbs water, running it harmlessly through the system. When using 100LL Avgas, water tends to accumulate in fuel tanks from condensation, particularly in partially fi lled tanks. Because water is heavier than fuel, it tends to collect in the low points of the fuel system. If Avgas is used, drain any water from the low point in the system. |

| ©AvStop Online Magazine Contact Us Return To Books |