|

|

||

| CHAPTER 5. Prefl ight and Ground Operations

Before Takeoff Check The before takeoff check is the systematic procedure for making a check of the engine, controls, systems, instruments, and avionics prior to fl ight. Normally, it is performed after taxiing to a position near the takeoff end of the runway. Taxiing to that position usually allows sufficient time for the engine to warm up to at least minimum operating temperatures. This ensures adequate lubrication and internal engine clearances before being operated at high power settings. Many engines require that the oil temperature or engine temperature reach a minimum value, as stated in the AFM/POH, before high power is applied. Some WSC aircraft are ram air cooled, where the cooling air must be rammed into the cooling radiator during fl ight. On the ground, however, little or no air is forced through the radiator. Prolonged ground operations may cause engine overheating. Some designs place the cooling radiators near the propeller so the propeller produces reasonable airfl ow to cool the engine. Air cooled two-stroke engine aircraft may have an integral engine driven cooling fan and can idle indefi nitely without overheating. Monitoring engine temperature to be within limits is important for aircraft operations on the ground. After taxiing to the runway entrance runup area and before beginning the pretakeoff check, the aircraft should be positioned clear of other aircraft. When you taxi out to the run up area, position your self where other aircraft can easily taxi to a suitable run up area. There should not be anything behind the aircraft that might be damaged by the prop blast. To minimize overheating during engine run-up, it is recommended that the aircraft be headed as nearly as possible into the wind. After an aircraft is properly positioned for the run-up, the nose wheel should be pointed straight. During the engine run-up, the surface under the WSC aircraft should be fi rm (a smooth, paved, or turf surface, if possible) and free of debris. Otherwise, the propeller may pick up pebbles, dirt, or other loose objects and hurl them backward or into the sail. [Figure 5-67]  While performing the engine run-up, the pilot must divide attention inside to look at the instruments and outside the aircraft to look for other traffi c. If the parking brake slips, or if application of the brakes is inadequate for the amount of power applied, the aircraft could move forward unnoticed if attention is fi xed only inside the aircraft. Each aircraft has different features and equipment, and the before takeoff checklist provided by the WSC manufacturer should be used to perform the run-up. Here is a general checklist.

At towered airports, obtain clearance from tower when ready for takeoff. At nontowered airports, when all air traffi c is clear from observations and radio communications and while holding short before the runway boundary (hold short) line, announce the aircraft is entering the runway. This is a pilot’s clearance at a self-announce airport to enter the runway. At all airports, do a visual verifi cation that there are no aircraft landing before entering the runway. After Landing During the after-landing roll, the WSC aircraft should be gradually slowed to normal taxi speed before turning off the landing runway. Any signifi cant degree of turn at faster speeds could result in the WSC aircraft tipping over and subsequent damage. [Figure 5-68]  To give full attention to controlling the WSC aircraft during the landing roll, the after-landing check should be performed only after the aircraft is brought to a complete stop clear of the active runway. Postfl ight, Parking, and Securing A fl ight is never complete until the engine is shut down and the WSC aircraft is secured. A pilot should consider this an essential part of any fl ight. Unless parking in a designated, supervised area, the pilot should select a location which prevents propeller or jet blast of other airplanes from striking the WSC aircraft. The pilot should always use the procedures in the manufacturer’s checklist for shutting down the engine and securing the airplane. Some of the important items include:

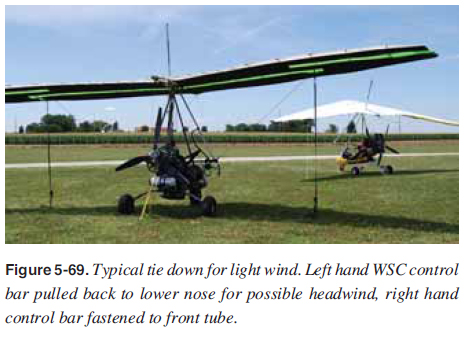

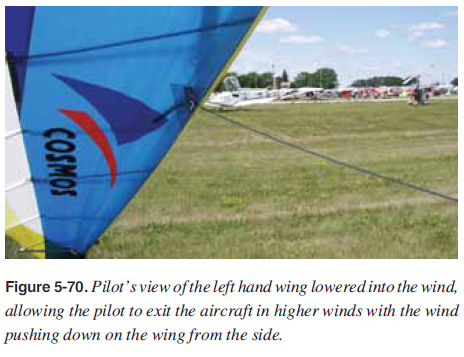

After engine shutdown and exiting the aircraft, the pilot should accomplish a postfl ight inspection. When the fl ight is complete, the aircraft should be hangared or tied down appropriately for the situation. There are a number of ways to park and secure the WSC aircraft depending on the situation. With normal aircraft tie downs, little to no wind, and a short time frame for unsupervised parking, the WSC aircraft can be secured by tying both leading edge cross bar junctions to the typical airport wing ties. The control bar is secured to the front tube with a bungee chord to stabilize the nose or the control bar can be pulled back and attached to the seat rail to keep the nose down in case of a possible headwind. [Figure 5-69]  If higher winds are present, the WSC aircraft can be positioned so the wind is blowing from the side and the wing tip is lowered on the windward side so the wind is pushing down on the wing. This can be used to exit the aircraft and tie the wing down in higher winds. [Figures 5-70 through 5-72]    For overnight or higher wind tie down, the complete wing can be lowered to the ground with a four point tie down. Each wing at the crossbar/leading edge junction plus the nose and rear of the keel can be tied down for greater resistance to wind. For humid or dusty areas, a cover is recommended for the carriage to cover the engine and fl ight deck. [Figure 5-73]  The best way to secure the WSC aircraft for overnight is to put it in a hangar. If it must be stored outside, remove the wing and fold it up so there is no chance of the wing being damaged in an unforeseen gust front. |

| ©AvStop Online Magazine Contact Us Return To Books |