ch6

CHAPTER 6 - CONTROL OF LOADING - GENERAL AVIATION

Before any flight, the pilot should determine the weight and balance

condition of the aircraft. In the early days of flying, aircraft were loaded

by guess and intuition. On occasion, the results were grim. Through trial

and error the early pilots learned about weight and balance. Today there

is no excuse for following this method. Simple and orderly procedures based

on sound principles have been devised by aircraft manufacturers for the

determination of loading conditions. The pilot, however, must use these

procedures and exercise good judgment. In many modern aircraft, it is not

possible to fill all seats, baggage compartments, and fuel tanks and still

remain within the approved weight and balance limits. If the maximum passenger

load is carried, the pilot must often reduce the fuel load or reduce the

baggage.

| USEFUL LOAD CHECK

A simple and fundamental weight check should always be made by general

aviation pilots before flight. This check should determine if the useful

load is exceeded. The check may be a mental calculation if the pilot is

familiar with the aircraft's limits and knows that unusually heavy loads

are not aboard. But when all seats are being occupied, fuel tanks are full,

and some baggage is aboard, the pilot should do some careful calculations.

The pilot needs to know the useful load limit of the particular aircraft.

This information may be found in the latest weight and balance report,

in a log book, or on a major repair and alteration form, located in the

aircraft. If useful load is not stated directly, simply subtract empty

weight from maximum takeoff weight. Be especially weight conscious of aircraft

which have a limited useful load because they are the ones which cause

weight and balance troubles. |

|

|

|

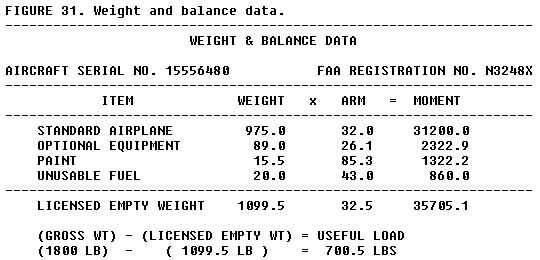

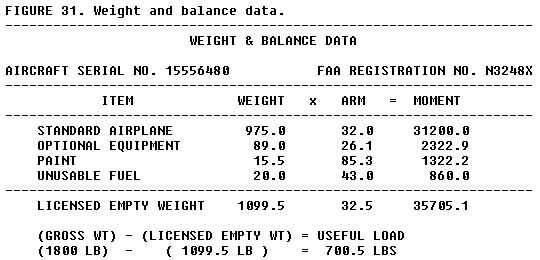

IT IS THE RESPONSIBILITY OF THE OWNER AND PILOT TO ENSURE THAT THE AIRPLANE

IS PROPERLY LOADED. THE DATA ABOVE INDICATES THE EMPTY WEIGHT, C.G., AND

USEFUL LOAD WHEN THE AIRPLANE WAS RELEASED FROM THE FACTORY. REFER TO THE

LATEST WEIGHT AND BALANCE RECORD WHEN ALTERATIONS HAVE BEEN MADE.

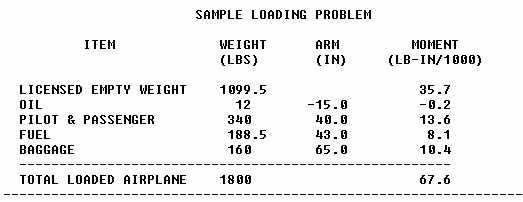

The check is simple enough - just be sure to include all the load items

included in the useful load - then check the total against the limit. The

calculations might look like this:

The calculations indicate that the useful load is not exceeded and the

flight can take place.

Now suppose that Mr. Jones, in the example, is replaced by a new instructor

who weighs 210 lb. A useful load check will show that the aircraft is too

heavy. The pilot in our example must reduce the load to the specified useful

load limit. There is no alternative in this small aircraft but to reduce

the fuel load, even if all the baggage has been removed.

Pilots should be aware of, and on the alert for, unusual loadings. They

should remember that the manufacturer's initial weight and balance calculations

and some examples in the owner's manual make the assumption that the pilot

and passengers weigh a standard 170 lb. each. Heavyweight passengers can

overload a small aircraft seriously. A student and instructor may easily

weigh 220 lb. each in winter clothing; this represents a potential overload

of 100 lb. The baggage compartment is another place where pilot vigilance

should be directed - the maximum compartment load placard must be obeyed.

Frequently, a restriction is placed on rear seat occupancy with the maximum

baggage aboard.

WEIGHT AND BALANCE RESTRICTIONS

Be sure to follow your aircraft's weight and balance restrictions. The

loading conditions and empty weight of your particular aircraft (fig.

31) may differ from those in the owner's manual due to modifications

or equipment changes. Sample loading problems in the owner's manual are

intended for guidance only; each aircraft must be treated separately for

weight and balance. The pilot should understand that although the aircraft

is certified for a specified maximum gross weight, it will not safely take

off with this load under all conditions. Conditions which affect takeoff

and climb performance such as high elevations, high temperatures, and high

humidity (high density altitudes), may require operation at reduced weight.

Other factors to consider are runway length, runway surface, runway slope,

surface wind, and the presence of obstacles. Pilot experience and proficiency

should always be considered - if in doubt, reduce the load.

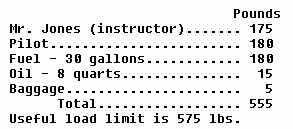

| Some small aircraft are designed so that it is not possible

to load them in a condition which will place the c.g. outside the fore

or aft limits if standard load schedules are observed. These aircraft have

the seats, fuel, and baggage accommodations located very near the c.g.

limits. They also have special empty weight c.g. limits listed in their

specifications. Loads can be added to or removed from any location within

the c.g. range with complete freedom from concern about c.g. movement.

Such action cannot cause the c.g. to move beyond the c.g. limits of these

aircraft (see fig. 32), but maximum weight limits can still be exceeded. |

|

Most aircraft, however, can be loaded in a manner which will place the

c.g. beyond limits. Even though the useful load is not exceeded, an out-of-balance

condition is serious from a stability and control standpoint. The pilot

can quickly determine if the load is within limits, if the aircraft is

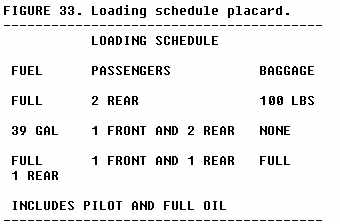

simple enough to make use of a loading schedule. This schedule may be found

in the weight and balance report, the aircraft log book, the owner's manual,

or may be posted in the form of a placard. A typical placard may appear

similar to the one shown in figure 33.

The loading schedule should be treated as a suggested loading plan only.

The pilot should make a check by means of weight and balance calculations

to see if limitations are not being exceeded. The assumption in the use

of the loading schedule is that each passenger weighs approximately the

standard weight of 170 lb. It is obvious that passenger weights could vary

widely from the assumed standard.

AIRPLANE FLIGHT MANUAL

Each airplane of over 6,000 lbs. maximum weight is furnished with an

airplane flight manual. An airplane of less than 6,000 lbs. may have information

furnished in the form of placards, markings, or manuals. When an airplane

flight manual is furnished, the following is included:

a. Limitations and data:

(1) The maximum weight.

(2) The empty weight and c.g. location.

(3) The useful load.

(4) The composition of the useful load, including the total weight

of fuel and oil with full tanks.

b. Load distribution:

The established c.g. limits are furnished in the airplane flight manual.

If the available loading space is adequately placarded or arranged so that

no reasonable distribution of the useful load will result in a c.g. outside

of the stated limits, the airplane flight manual may not include any information

other than the statement of c.g. limits. In other cases, the manual includes

enough information to indicate loading combinations that will keep the

c.g. within established limits.

LIGHT SINGLE ENGINE AIRCRAFT LOADING PROBLEMS

| Aircraft manufacturers use one of several available systems

to provide the aircraft loading information. The following weight and balance

problems will show how the pilot can determine if the maximum weight limit

is exceeded or the c.g. is located beyond limits.

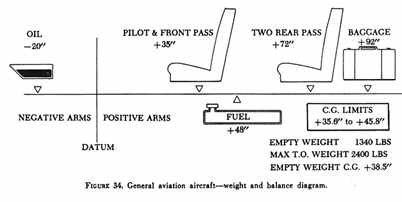

Assume you are a pilot planning a flight in a light single engine, four

place aircraft. Your load consists of yourself, one front seat passenger

and two rear seat passengers, full fuel and oil, and 60 lb. of baggage

(fig. 34). Here is how the critical weight and balance problems are solved

for this case by two different methods (examples 23 and 24). |

|

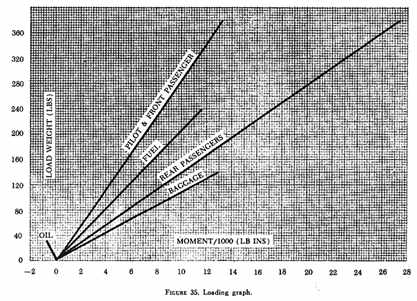

EXAMPLE 23.

Solution by index table:

1. From the manual or weight and balance report, determine the empty

weight and empty weight c.g. (arm) of the aircraft.

2. Determine the arms for all useful load items.

3. Determine the maximum weight and c.g. range. (For this case - Max.

TOGW = 2,400 lb., c.g. range - Sta. 35.6 to 45.8.)

4. Calculate the actual weights for the useful load items.

5. Construct a table as follows, and enter the appropriate values.

Multiply each individual weight and arm to obtain moments.

NOTE - Observe that the oil tank for this aircraft is located forward

of the datum. Care must be taken to subtract the negative oil moment when

totaling the moment column.

6. Adding the weights produces a total of 2,276 lb., and adding the

moments produces a total of 101,178 lb-in. The c.g. is calculated by dividing

the total moment by the total weight:

101,178

------- = 44.5 in aft of datum

2,276

7. The total weight of 2,276 lb. does not exceed the maximum weight

of 2,400 lb., and the computed c.g. of 44.5 falls within the allowable

c.g. range of 35.6 to 45.8 in. aft of datum.

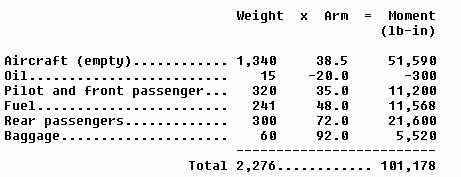

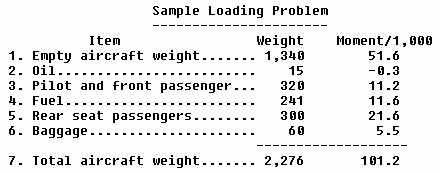

| Weight and balance computations are greatly simplified

by two graphic aids - the loading graph and the center of gravity moment

envelope. The loading graph (fig. 35) is typical of those found in general

aviation aircraft owner's manuals. This graph, in effect, multiplies weight

by arm giving moment, then divides the moment by a reduction factor, giving

an index number. Weight values appear along the left side of the graph.

The moment/1,000 or index numbers are along the bottom. In this example,

each line representing a load item is labeled. To determine the moment

of any load item, find the weight along the left margin, then project a

line right to a point of intersection with the appropriate load item line.

For example, the index number of a pilot weighing 170 lb. is 6.1. |

|

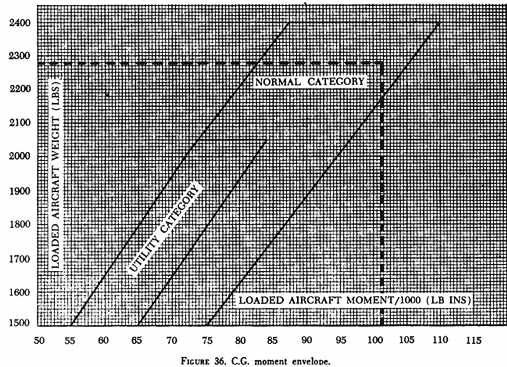

The c.g. moment envelope (fig. 36) allows the pilot to

bypass the computation of a c.g. number. It gives an acceptable range of

index numbers for any aircraft weight from minimum to maximum.

If the lines from total weight and total moment intersect within the

envelope, the aircraft is within weight and balance limits. In solving

the sample problem, follow this procedure:

EXAMPLE 24.

1. Determine the aircraft empty weight and the empty weight index from

the weight and balance report.

2. Construct a table such as the one |

|

that follows. In the left column, enter the actual weights of the

empty aircraft, oil, pilot and front seat passenger, fuel, rear seat passenger,

and baggage. In the right column, enter the aircraft empty weight index

(moment/1,000).

3. From the loading graph, fig. 35, determine the

index number (moment/1,000) of each useful load weight item and enter it

in the table.

4. Add the weight and moment columns and write in the totals.

5. Refer to the c.g. moment envelope, fig. 36, and

find the point of intersection of a line projected right from total weight

(2,276 lbs.) and of a line projected up from total moment/1,000 (101.2).

6. The point of intersection falls within the envelope, therefore, the

weight and c.g. are within limits.

LIGHT TWIN ENGINE AIRCRAFT

Modern light twin engine aircraft are larger than most single engine

aircraft; accordingly, their useful load is almost always greater than

that found in the smaller aircraft. In these aircraft, it is possible to

have many different loading combinations. Their large baggage compartments

may be full or empty, and there may be wide variations in the number of

seats being occupied. These variations are to be expected and are normal

for the types of operations for which the aircraft are used. However, the

c.g. is bound to range backward and forward as the loads are varied; therefore,

weight and balance control is essential.

If a variety of loads can be placed aboard an aircraft in a number of

locations, the pilot must be especially aware of duties regarding weight

and balance control. Pilots should use a reliable weight and balance system,

preferably the type recommended by the manufacturer, to assure that the

weight and balance is within limits for each flight. They should insist

that passengers are assigned to the correct seat from a weight distribution

standpoint. They should also be sure that passenger baggage or miscellaneous

cargo is properly loaded.

The weight and balance systems used on light twin engine aircraft are

essentially the same as those used for single engine aircraft. Weights,

arms, and moments are the basic factors, and the final c.g. computation

must fall within the allowable c.g. limits. Many twin engine aircraft make

use of the loading graph and moment envelope system (figs. 35

and 36). Other models make use of index tables similar

to those explained earlier for single engine aircraft (fig.

24).

Some light twin engine aircraft have weight and balance control systems

which make use of a special weight and balance plotter. The typical plotter

is made of plastic material similar to an aeronautical computer. It consists

of several movable parts which can be adjusted over a plotting board on

which is printed a c.g. envelope. The reverse side of the typical plotter

contains general loading recommendations for the particular aircraft. The

recommendations may suggest that occupants be loaded progressively from

front to rear. In other words, the forward and center seats should be occupied

before passengers are assigned to the rear seats. A pencil line plot can

be made directly on the envelope imprinted on the working side of the plotting

board. This plot can be erased and recalculated anew for each flight. The

plotter is to be used only for the aircraft for which it was designed.

This weight and balance control system is very similar to one used on air

carrier aircraft as illustrated by figure 57.

A typical weight and balance plotter should contain this reminder: "It

is the responsibility of the owner and pilot to ascertain that the aircraft

always remains within the allowable weight versus c.g. envelope while in

flight." This note should serve as a precaution to the pilot to be sure

to check the weight and balance condition before takeoff and to be sure

that any shift in passenger seating locations does not adversely affect

the location of the aircraft center of gravity.

HIGH DENSITY SEATING AIRCRAFT

Many light twin engine aircraft are being used for transportation of

passengers, cargo, or mail in the form of commuter or air taxi service

to supplement the scheduled and unscheduled air carriers. An increasing

number of twin engine aircraft are being used to carry mail on a scheduled

basis. Many commuter and air taxi operators carry passengers to and from

small cities to make connections with trunk carriers at airports in large

cities. The aircraft used for this purpose are in some cases fitted with

a large number of seats in relation to fuselage size and are called high

density seating aircraft. The aircraft may contain seats for eight to 15

passengers and some of the larger types may seat over 25 passengers. The

loading problems are relatively more complex than for aircraft which carry

only six passengers. The complexity of the loading situation approaches

that encountered in air carrier operations. Weight and balance limits for

high density seating aircraft must be respected. The passenger, cargo,

or mail load on high density seating aircraft may vary considerably from

flight to flight. Some trips may be made with a full load and others with

a minimum load. Some of the high density seating aircraft have special

weight and balance problems because they have been modified and modernized

from older aircraft which originally did not have a great number of seats.

Some of these modified aircraft are very sensitive as far as loading toward

the rear limit is concerned. The recommended weight and balance checking

procedures for modified aircraft must be carefully followed and operators

should be sure to make a thorough analysis of weight and balance records

to assure currency.

An operator's manual, when required for high density seating aircraft,

should contain procedures for assuring compliance with weight and balance

limits, including periodic reweighing of the aircraft. The weight and balance

procedures contained in the manual should:

1. Be based on sound principles, using standardized terminology, and

be compatible with the type(s) of aircraft operated.

2. When followed, assure that the aircraft is properly loaded and will

not exceed authorized weight and balance limitations during operation.

3. Provide for blocking off seats or compartments when necessary to

remain within c.g. limits. Effective means should be provided to assure

that those seats and compartments are not occupied during operations specified.

4. Provide crewmembers, cargo handlers, and other personnel concerned

complete information regarding distribution of passengers, fuel, and other

items, and should give complete information regarding the distribution

and security of cargo to prevent the shifting of weight in flight.

5. Provide other information relative to maximum weights, capacities,

and other pertinent limitations affecting the weight and balance of the

aircraft.

Pilots of these high density seating aircraft must be aware of the effect

of passenger and cargo location on c.g., and they must have a personal

knowledge of the means of correcting an out-of-limits condition. They often

have no one to assist them with loading problems; they act as pilot, dispatcher,

and loading agent in many cases.

In commuter or air taxi operations, pilots are confronted with the problem

of frequent trips with varying loads. They need to have a positive, accurate,

and fast way to compute the weight and balance. They must have reliable

empty weight and c.g. information readily available for use. This information

must be updated to account for all the modifications performed on the aircraft.

A load manifest, when required for air taxi or commercial operations,

should contain the following information concerning the aircraft loading

at takeoff time:

1. The weight of the aircraft, fuel and oil, cargo (including mail and

baggage), and passengers;

2. The maximum allowable weight for that flight;

3. The total weight computed under approved procedures;

4. Evidence that the aircraft is loaded according to an approved schedule

that insures that the c.g. is within approved limits.

|

|

The execution of a load manifest is always a highly recommended procedure

from the standpoint of making a uniform preflight check of the weight and

balance condition. A typical load manifest may be a simple form similar

to that illustrated in figure 37. This form provides

a record of passengers and of all useful loads for the particular flight.

The major advantage of such a form is that the pilot has a standardized

means of calculating and recording the weight and balance condition of

the aircraft for each flight. If care is taken to carry forward or make

proper record of the empty weight and c.g., the pilot can be spared the

task of a search through aircraft records for this vital information. The

form may also be used as a record of passenger identification as may be

needed for administrative purposes.

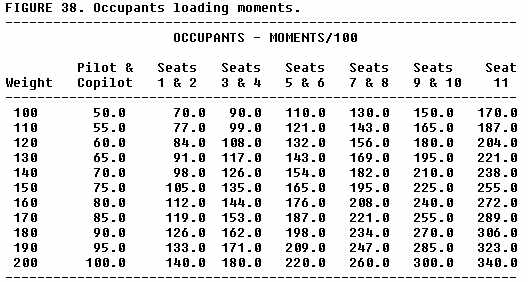

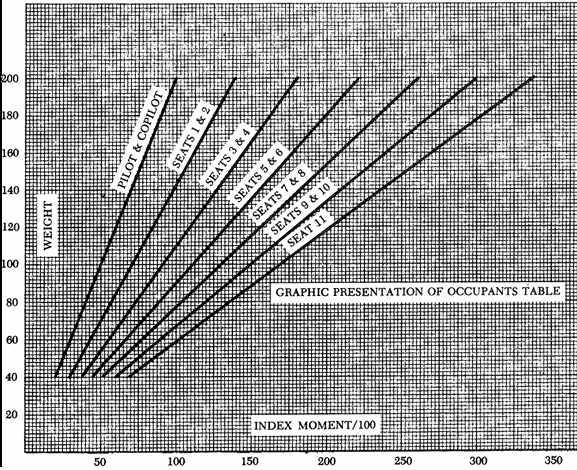

One typical weight and balance control system for high density seating

aircraft is based upon the utilization of useful load index tables and

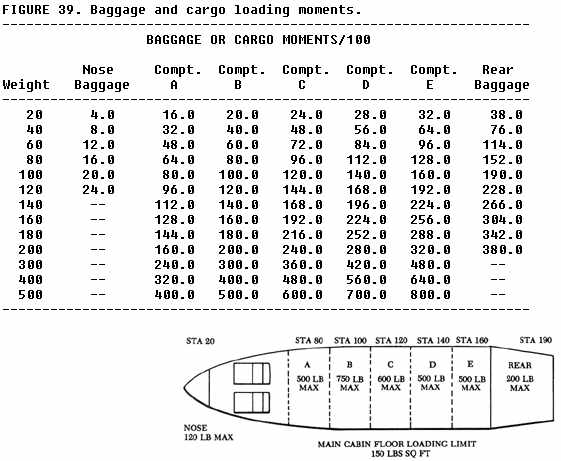

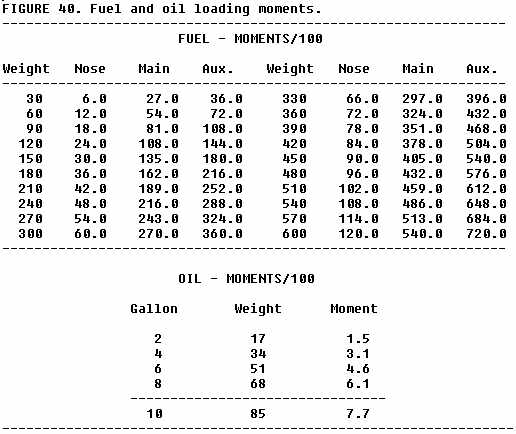

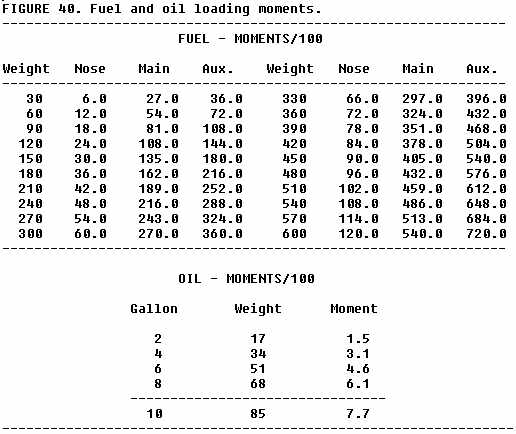

a total weight index limit envelope or table. With these tables (figs.

38, 39, 40, 41),

it is possible to determine if weight and balance is within limits even

in a situation where the passenger, cargo, or fuel loads change fairly

rapidly. The tables can be read for intermediate weights by interpolation

of values. To simplify and speed up calculations, use the nearest listed

weight, but be conservative when checking against particular limits. The

system is generally similar to those discussed on smaller aircraft. The

pilot adds the weight and moments (index) of the empty aircraft and the

useful load items. Then, checks are made against the published limits in

this case the index limit envelope or table. Care must be taken to use

the empty weight and moments or index from the latest weight and balance

report. The pilot must be sure to use the same reduction factor for all

moments in the calculations. Sufficient accuracy is obtained by rounding

off index numbers to the nearest tenth.

EXAMPLE 25.

Assume you are a pilot planning a flight in an air taxi aircraft. Your

load consists of yourself, your copilot, 11 passengers, 300 pounds of fuel

in each of the main tanks, 120 pounds of fuel in each of the auxiliary

tanks, 75 pounds of oil, 100 pounds of baggage in the nose compartment,

and 200 pounds of baggage in the rear compartment. The sample manifest

form in figure 37 has been completed to show the

useful load and empty weight items. Use the loading tables and total weight

index limit table shown in figures 38, 39,

40, 41 to determine if the aircraft

is properly loaded for takeoff. The intersection of the dotted weight and

moment/100 lines in figure 41 shows that limits are

not being exceeded.

TWIN ENGINE CARGO AIRCRAFT

Small twin engine aircraft can be used effectively for carrying cargo

into airports where operations would not be practical with transport aircraft.

Cargo which is particularly suitable for twin engine aircraft are high

value items or items which must reach local destinations quickly. The scheduled

transportation of mail to small cities and towns is an example of the type

service these aircraft provide.

Light twin engine aircraft can be designed for more effective cargo

operations if some special loading and handling features are employed.

Large size cargo doors are a great help when bulky packages are to be loaded.

Without the use of large doors, the cargo space may be restricted because

big packages cannot be maneuvered through the passenger type doors. Provisions

for securing the cargo to the aircraft structure are also needed. Normally,

tiedown rings are attached to the floor and to structural members of the

side walls for this purpose.

Many of the high density twin engine aircraft can be quickly converted

from passenger to cargo use by removing the seats from the main cabin area

(fig. 42). In some cases, cargo is carried in the

passenger seats and secured by the regular seat belt. It is also possible

that only one or two passenger seats will be removed, resulting in a mixture

of cargo and passengers in the main cabin. Measures must be taken in this

case to protect the passengers from possible cargo movement.

The following are recommended for the loading of cargo in other than

approved cargo compartments or bins:

a. If passengers are carried, the cargo must be carried forward of the

foremost passenger.

b. The cargo should be properly secured by a safety belt or other tiedown

device to prevent it from becoming a hazard by shifting.

c. The cargo must not impose any load on seats or the floor structure

that exceeds the load limitations for these components.

d. The location of the cargo must not restrict access to or use of any

required emergency or regular exit by any passenger, or access to an emergency

exit by a pilot if a regular exit is not accessible to the pilot.

e. The location of the cargo must not obscure any passenger's view of

any required sign, unless an auxiliary sign or other approved means for

proper instruction or notification is provided.

Cabin cargo is in danger of shifting if the deck angle (floor attitude)

is not level as during the rotation and initial climb at takeoff. Unrestrained

cargo will shift rearward in this event and cause a tail-heavy condition

which may lead to a dangerous takeoff stall. Cabin cargo is also subjected

to inertia forces resulting from turbulence, acceleration, deceleration,

vibration, and hard landings. These inertia forces act more strongly in

some directions than in others and tend to shift the cargo unless it is

properly restrained. A forward force is the one most likely to act on cargo.

This force may result from a sudden application of brakes, landing on a

soft sod runway, or a crash landing. That is why cargo should be located

forward of all passengers in a mixed-load configuration. Cargo must also

be secured from moving aft, from side to side (laterally), or up and down

(vertically).

Cargo may be secured by means of tiedown devices such as straps, ropes,

or nets. These devices, when properly used, will restrain the cargo from

moving in any direction. Tiedown fittings should be adequate in number

and strength to restrain a cargo of any allowable weight and size. Floor

structure, particularly where the tiedown fittings are anchored, must be

strong enough to resist any anticipated load without distortion. Cargo

floor loading limits are usually expressed as maximum weight in pounds

per square foot. If a cargo item is loaded in a seat, the pilot would be

wise to limit its weight to that of an average passenger. A tiedown or

safety belt should restrain its movement in the seat (fig.

43). A single cargo item on the cabin floor should be secured in a

manner similar to that shown in figure 44. Its center

of gravity may be determined by the method shown in figure 45.

The following general precautions should be observed when actually loading

the cargo:

1. In a tailwheel aircraft, cylindrical items on their sides should

be chocked until lashed down.

2. Liquid containers should be placed with their outlets at the top.

3. Lightweight items should be stacked on heavier items, or stacked

separately.

4. Shoring or planking must be used when the contact area is likely

to exceed the floor strength limitations.

Many cargo loads carried in air taxi aircraft will consist of a variety

of boxes, crates, sacks, drums, etc. This type of composite cargo may be

secured with the type devices shown in figures 46

and 47. Sufficient restraint should be used to prevent

shifting because of high deck angle or inertia forces. In arranging composite

loads, cargo items should not be arranged so the load is top-heavy. If

possible, the height of the load should not exceed its length. Particular

care should be taken to secure this type load against slipping out from

under the tiedown device. If the individual items of this type cargo are

comparatively light, a net type tiedown device is adequate. Heavy items

will require ropes or straps.

Cargo should be placed as near to the c.g. of the airplane as possible,

roughly at the 30% chord point; but limitations of particular areas should

be observed to prevent overloading the structure. Care must also be taken

not to block access to an exit in the rear of the cabin or to cut off an

aisle needed for inflight inspection of the main cabin cargo.

EXAMPLE 26.

This problem is an example of the use of a manifest form to determine

the weight and balance condition of a cargo flight. The airplane is the

same one used in example 25 with the seats removed from the main cabin.

Notice that the empty weight and moments have been changed due to the removal

of the seats. This change must be carefully noted according to the manufacturer's

recommendations. The sample manifest form in figure 48

has been completed to show the useful load and empty weight items.

Using the loading tables and total weight index table shown in figures

38, 39, 40, 41

to determine the loading condition of the aircraft, you should obtain a

moment of 10038.7 index units. It is apparent when the index limit table

is checked that the cargo is loaded too far to the rear. The aircraft is

not safe or legal to fly in this loaded condition. The maximum index limit

(rear c.g. limit) has been exceeded by 20.7 index units (2070.0 lb-in).

If the cargo in compartment E consists of cartons, each weighing 20 pounds,

how many cartons must be moved to compartment A to bring the index within

the maximum limit?

The baggage or cargo table can be used to help determine how much cargo

must be shifted. At least two methods are available:

1. Select the cargo weight which would make a difference of at least

20.7 index units when compartments A and E are compared. (40 lb. = 64.0

- 32.0 = 32.0 index units)

2. Determine the difference in arms between compartments A and E (Sta.

160 - Sta. 80 = 80 inch). Divide the excessive moments by this arm (2070.0

/ 80 = 25.9 lb.).

By use of either method we can see that the movement of 40 lb. (two

each 20 lb cartons) would be required to reduce the index by at least 20.7.

A new passenger and cargo manifest should now be executed to prove that

the c.g. is within limits with the proposed new load distribution. Of course,

it would be possible to shift a greater number of cartons than the minimum

to be on the safe side. In any case, care must be taken to remain within

the compartment maximum weight limit, the floor loading limit, and the

minimum and maximum index limits.

HELICOPTER WEIGHT AND BALANCE

The weight and balance principles and procedures which have been described

in connection with airplanes apply generally to helicopters. Each model

helicopter is certificated for a specific maximum gross weight. However,

it is not safe to operate at this maximum weight under all conditions.

Combinations of high altitude, high temperature, and high humidity determine

the density altitude at a particular location. This, in turn, critically

affects the hovering, takeoff, climb, autorotation, and landing performance

of a helicopter. Additional factors to be considered are wind, obstacles,

type of surface, and space available for takeoff and landing. Just because

a helicopter can take off with a heavy load does not mean that flight with

that load will be safe. A heavily loaded helicopter has less ability to

withstand shocks and additional airloads caused by turbulence. The greater

the weight, the less the margin of safety for the supporting structures

such as the main rotor, fuselage, and landing gear.

Most helicopters have a much more restricted c.g. range than do airplanes.

In some cases this range is less than 3 inches. The exact location and

length of the c.g. range is specified for each helicopter and usually extends

a short distance fore and aft of the main rotor mast or the centroid of

a dual rotor system. Ideally, the helicopter should have such perfect balance

that the fuselage remains horizontal while in a hover and the only cyclic

adjustment required should be that made necessary by the wind. The fuselage

acts as a pendulum suspended from the rotor. Any change in the c.g. changes

the angle at which it hangs from this point of support. Many recently designed

helicopters have loading compartments and fuel tanks located at or near

the balance point. If the helicopter is not loaded properly and the c.g.

is not very near the balance point, the fuselage does not hang horizontal

in a hover. If the c.g. is too far aft, the nose tilts up and excessive

forward cyclic is required to maintain a stationary hover. Conversely,

if the c.g. is too far forward, the nose tilts down and excessive aft cyclic

is required (fig. 49). In extreme out-of-balance conditions,

full fore or aft cyclic may be insufficient to maintain control. Similar

lateral balance problems may be encountered if external loads are carried.

Upon delivery by the manufacturer, the empty weight, empty weight c.g.,

and the useful load are noted on the weight and balance data sheet in the

helicopter flight manual. If, after delivery additional fixed equipment

is added or removed, or if a major repair or alteration is made which may

affect the empty weight, empty weight c.g., or useful load, the weight

and balance data must be revised. All weight and balance changes should

be entered in the appropriate aircraft record. The helicopter flight manual

includes directions for solving loading problems. The procedures are similar

to those already described for airplanes. For further information, read

the FAA Basic Helicopter Handbook, AC

61-13A.