2-10

Mixture Control

A “mixture control” in the cockpit is provided to change the fuel

flow to the engine to compensate for varying air densities as the airplane

changes altitude.

Carburetors are normally calibrated at sea level pressure to meter

the correct amount of fuel with the mixture control in a “full rich” position.

As altitude increases, air density decreases. This means that a given volume

of air does not weigh as much at higher altitudes because it does not contain

as many air molecules. As altitude increases, the weight of air decreases,

even though the volume of air entering the carburetor remains the same.

To compensate for this difference, the mixture control is used to adjust

the ratio of fuel-to-air mixture entering the combustion chamber. This

also regulates fuel consumption.

If the fuel/air mixture is too rich, i.e., too much fuel in terms

of the weight of air, excessive fuel consumption, rough engine operation,

and appreciable loss of power will occur. Because of excessive fuel, a

cooling effect takes place which causes below normal temperatures in the

combustion chambers. This cooling results in spark plug fouling. Conversely,

operation with an excessively lean mixture, i.e., too little fuel in terms

of the weight of air, will result in rough engine operation, detonation,

overheating, and a loss of power.

To summarize, as the airplane climbs and the atmospheric pressure

decreases, there is a corresponding decrease in the weight of air passing

through the induction system. The volume of air, however, remains constant,

and since it is the volume of airflow which determines the pressure drop

at the throat of the venturi, the carburetor tends to meter the same amount

of fuel to this thin air as to the dense air at sea level. Therefore, the

mixture becomes richer as the airplane gains altitude. The mixture control

prevents this by decreasing the rate of fuel discharge to compensate for

the decrease in air density. However, the mixture must be enriched when

descending from altitude.

Follow the manufacturer’s recommendation for the particular airplane

being flown to determine the proper leaning/enriching procedures.

| Carburetor Icing

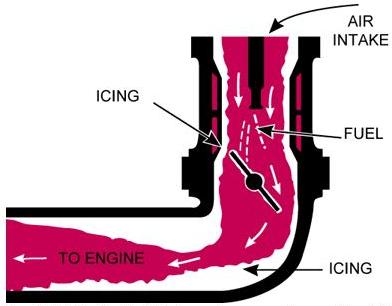

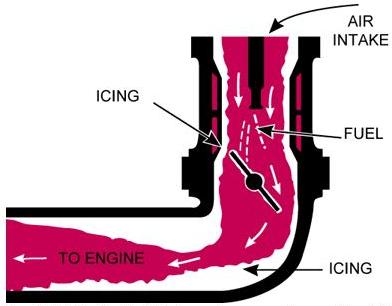

The vaporization of fuel, combined with the expansion of air as

it flows through the carburetor, causes a sudden cooling of the mixture.

The temperature of the air passing through the carburetor may drop significantly

within a fraction of a second. Water vapor in the air is “squeezed out”

by this cooling and, if the temperature in the carburetor reaches 0°

C (32° F) or below, the moisture will be deposited as frost or ice

inside the carburetor passages. Even a slight accumulation of this deposit

will reduce power and may lead to complete engine failure, particularly

when the throttle is partly or fully closed. [Figure 2-8]

Conditions Conducive to Carburetor Icing

On dry days, or when the temperature is well below freezing, the

moisture in the air is not generally enough to cause trouble. But if the

temperature is between -7° C (20° F) and 21° C (70° F),

with visible moisture or high humidity, the pilot should be constantly

on the alert for carburetor ice. During low or closed throttle settings,

an engine is particularly susceptible to carburetor icing. |

|

|

Figure 2-8.—Formation of ice (white) in the fuel intake system may

reduce or block fuel flow (red) to the engine. |