There are several grades of aviation fuel available; therefore, care must be exercised to assure that the correct aviation grade is being used for the specific type of engine. It can be harmful to the engine and dangerous to the flight if the wrong kind of fuel is used. It is the pilot’s responsibility to obtain the proper grade of fuel. The proper grade is stated in the Aircraft Flight Manual or Pilot’s Operating Handbook, on placards in the cockpit, and next to the filler caps.

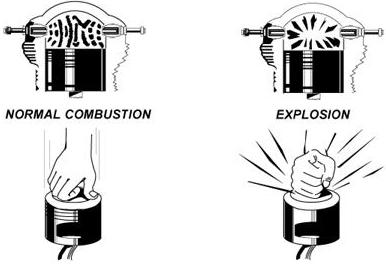

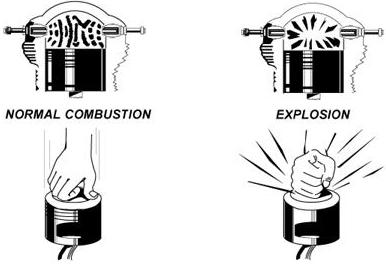

| The proper fuel for an engine will burn smoothly from the spark plug outward, exerting a smooth pressure downward on the piston. Using low-grade fuel or too lean a mixture can cause detonation. Detonation or knock is a sudden explosion or shock, to a small area of the piston top, similar to striking it with a hammer. Detonation produces extreme heat which often progresses into preignition, causing structural stresses on parts of the engine. Therefore, to prevent detonation, the pilot should use the proper grade of fuel, maintain a sufficiently rich mixture, and maintain engine temperatures within the recommended limits. [Figure 2-9] |

|

| Figure 2-9.—Normal combustion and explosive combustion. |

Airplane engines are designed to operate using a specific grade of fuel as recommended by the manufacturer. Lower numbered octane fuel is used in lower compression engines because these fuels ignite at a lower temperature. Higher octane fuels are used in higher compression engines because they must ignite at higher temperatures but not prematurely. If the proper grade of fuel is not available, it is possible, but not desirable, to use the next higher grade as a substitute.

Dyes are added to aviation fuels to assist in identification of the proper fuel grade.

GRADE COLOR

80 RED

100 GREEN

100LL BLUE

TURBINE COLORLESS

It should be noted that if fuel grades are mixed together they will become clear or colorless.

Fuel Contamination

Water and dirt in fuel systems are dangerous; the pilot must either eliminate or prevent contamination. Of the accidents attributed to powerplant failure from fuel contamination, most have been traced to:

• Inadequate preflight inspection by the pilot.

• Servicing of aircraft with improperly filtered fuel from small tanks

or drums.

• Storing aircraft with partially filled fuel tanks.

• Lack of proper maintenance.

To help alleviate these problems, fuel should be drained from the fuel strainer quick drain and from each fuel tank sump into a transparent container and be checked for dirt and water. Experiments have shown that when the fuel strainer is being drained, water in the tank may not appear until all the fuel has been drained from the lines leading to the tank. This indicates that the water remains in the tank and is not forcing the fuel out of the fuel lines leading to the fuel strainer. Therefore, drain enough fuel from the fuel strainer to be certain that fuel is being drained from the tank. The amount will depend on the length of fuel line from the tank to the drain. If water is found in the first sample, drain further samples until no trace appears.

Experiments have also shown that water will still remain in the fuel tanks after the drainage from the fuel strainer had ceased to show any trace of water. This residual water can be removed only by draining the fuel tank sump drains.

The pilot should be able to identify suspended water droplets in the fuel from a cloudy appearance of the fuel; or the clear separation of water from the colored fuel which occurs after the water has settled to the bottom of the tank. Water is the principal contaminant of fuel, and to increase flight safety, the fuel sumps should be drained during preflight.

In addition to the above measures, the following should be considered. The fuel tanks should be filled after each flight, or at least after the last flight of the day. This will prevent moisture condensation within the tank since no air space will be left. If the pilot chooses to refuel with only the amount that can be carried on the next flight—perhaps a day later—there is an added risk of fuel contamination by moisture condensation within the tank. Each additional day may add to the amount of moisture condensation within the tank or tanks.

Another preventive measure the pilot can take is to avoid refueling from cans and drums. This practice introduces a major likelihood of fuel contamination.

As has been pointed out, the practice of using a funnel and chamois

skin when refueling from cans or drums is hazardous under any condition,

and should be discouraged. It is recognized, of course, that in remote

areas or in emergency situations, there may be no alternative to refueling

from sources with inadequate anticontamination systems, and a chamois skin

and funnel may be the only possible means of filtering fuel.

In addition, it should be clearly understood that the use of

a chamois will not always assure decontaminated fuel. Worn out chamois

will not filter water; neither will a new, clean chamois that is already

water-wet or damp. Most imitation chamois skins will not filter water.

There are many filters available that are more effective than the old chamois

and funnel system.

Refueling Procedures

Static electricity, formed by the friction of air passing over

the surfaces of an airplane in flight and by the flow of fuel through the

hose and nozzle, creates a fire hazard during refueling. To guard against

the possibility of a spark igniting fuel fumes, a ground wire should be

attached to the aircraft before the cap is removed from the tank. The refueling

nozzle should be grounded to the aircraft before refueling is begun and

throughout the refueling process. The fuel truck should also be grounded

to the aircraft and the ground.

If fueling from drums or cans is necessary, proper bonding and grounding connections are extremely important, since there is an ever present danger of static discharge and fuel vapor explosion. Nylon, dacron, or wool clothing are especially prone to accumulate and discharge static electricity from the person to the funnel or nozzle. Drums should be placed near grounding posts and the following sequence of connections observed:

• Drum to ground.

• Ground to aircraft.

• Drum to aircraft.

• Nozzle to aircraft before the aircraft tank cover is opened.

• When disconnecting, reverse the order.

The passage of fuel through a chamois increases the charge of static electricity and the danger of sparks. The aircraft must be properly grounded and the nozzle, chamois filter, and funnel bonded to the aircraft. If a can is used, it should be connected to either the grounding post or the funnel. Under no circumstances should a plastic bucket or similar nonconductive container be used in this operation.

Oil System

Proper lubrication of the engine is essential to the extension

of engine life and prevention of excessive maintenance.

The oil system provides a means of storing and circulating oil

throughout the internal components of a reciprocating engine. Lubricating

oil serves two purposes: (1) it furnishes a coating of oil over the surfaces

of the moving parts, preventing direct metal-to-metal contact and the generation

of heat, and (2) it absorbs and dissipates, through the oil cooling system,

part of the engine heat produced by the internal combustion process.

Usually the engine oil is stored in a sump at the bottom of the engine crankcase. An opening to the oil sump is provided through which oil can be added and a dipstick is provided to measure the oil level in the sump.

A pump forces oil from the sump to the various parts of the engine that require lubrication. The oil then drains back to the sump for recirculation.

Each engine is equipped with an oil pressure gauge and an oil temperature gauge which are monitored to determine that the oil system is functioning properly.

Oil pressure gauges indicate pounds of pressure per square inch (PSI), and are color coded with a green arc to indicate the normal operating range. Also, at each end of the arc, some gauges have a red line to indicate high oil pressure, and another red line to indicate low oil pressure.

The oil pressure indication varies with the temperature of the oil. If the oil temperature is cold, the pressure will be higher than if the oil is hot.

A loss of oil pressure is usually followed by engine failure. If this occurs while on the ground, the pilot must shut the engine down immediately; if in the air, land at a suitable emergency landing site.

The oil temperature gauge is calibrated in either Celsius or Fahrenheit and color coded in green to indicate the normal temperature operating range.

It is important that the pilot check the oil level before each flight. Starting a flight with an insufficient oil supply can lead to serious consequences. The airplane engine will burn off a certain amount of oil during operation, and beginning a flight when the oil level is low will usually result in an insufficient supply of oil before the flight terminates.

There are many different types of oil manufactured for aviation use. The engine manufacturer’s recommendation should be followed to determine the type and weight of oil to use. This information can be found in the Aircraft Flight Manual or Pilot’s Operating Handbook, or on placards on or near the oil filler cap.