DCGENERATORS

DC GENERATORS

Energy for the operation of most electrical equipment in an airplane

depends upon the electrical energy supplied by a generator. A generator

is any machine which converts mechanical energy into electrical energy

by electromagnetic induction. A generator designed to produce alternating

current energy is called an ac generator, or alternator; a generator which

produces direct current energy is called a dc generator. Both types operate

by inducing an ac voltage in coils by varying the amount and direction

of the magnetic flux cutting through the coils.

For airplanes equipped with direct current electrical systems, the dc

generator is the regular source of electrical energy. One or more dc generators,

driven by the engine, supply electrical energy for the operation of all

units in the electrical system, as well as energy for charging the battery.

The number of generators used is determined by the power requirement of

a particular airplane. In most cases, only one generator is driven by each

engine, but in some large airplanes, two generators are driven by a single

engine. Aircraft equipped with alternating current systems use electrical

energy supplied by ac generators, also called alternators.

Theory of Operation

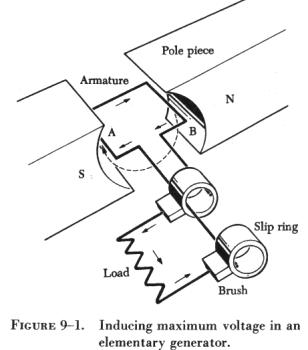

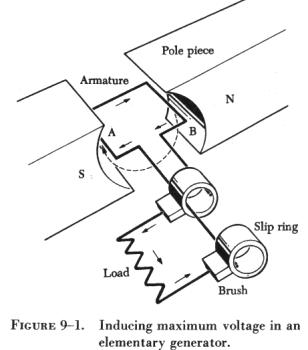

| In the study of alternating current, basic generator principles

were introduced to explain the generation of an ac voltage by a coil rotating

in a magnetic field. Since this is the basis for all generator operation,

it is necessary to review the principles of generation of electrical energy.

When lines of magnetic force are cut by a conductor passing through

them, voltage is induced in the conductor. The strength of the induced

voltage is dependent upon the speed of the conductor and the strength of

the magnetic field. If the ends of the conductor are connected to form

a complete circuit, a current is induced in the conductor. The conductor

and the magnetic field make up an elementary generator. This simple generator

is illustrated in figure 9-1, together with the components of an external

generator circuit which collect and use the energy produced by the simple

generator. The loop of wire (A and B of figure 9-1) is arranged to rotate

in a magnetic field. When the plane of the loop of wire is parallel to

the magnetic lines of force, the voltage induced in the loop causes a current

to flow in the direction indicated by the arrows in figure 9-1. The voltage

induced at this position is maximum, since the wires are cutting the lines

of force at right angles and are thus cutting more lines of force per second

than in any other position relative to the magnetic field. |

|

As the loop approaches the vertical position shown in figure

9-2, the induced voltage decreases because both sides of the loop (A

and B) are approximately parallel to the lines of force and the rate of

cutting is reduced.

When the loop is vertical, no lines of force are cut since the wires

are momentarily traveling parallel to the magnetic lines of force, and

there is no induced voltage. As the rotation of the loop continues, the

number of lines of force cut increases until the loop has rotated an additional

90° to a horizontal plane. As shown in figure 9-3,

the number of lines of force cut and the induced voltage once again are

maximum. The direction of cutting, however, is in the opposite direction

to that occurring in figure 9-1 and figure 9-2, so

the direction (polarity) of the induced voltage is reversed.

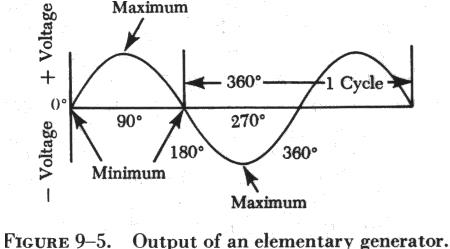

| As rotation of the loop continues, the number of lines

of force having been cut again decreases, and the induced voltage becomes

zero at the position shown in figure 9-4, since the

wires A and B are again parallel to the magnetic lines of force. If the

voltage induced throughout the entire 360° of rotation is plotted,

the curve shown in figure 9-5 results. This voltage is called an alternating

voltage because of its reversal from positive to negative values - first

in one direction and then in the other. |

|

To use the voltage generated in the loop for producing a current flow

in an external circuit, some means must be provided to connect the loop

of wire in series with the external circuit. Such an electrical connection

can be effected by opening the loop of wire and connecting its two ends

to two metal rings, called slip rings, against which two metal or carbon

brushes ride. The brushes are connected to the external circuit.

By replacing the slip rings of the basic ac generator with two half

cylinders, called a commutator, a basic dc generator (figure

9-6), is obtained. In this illustration the black side of the coil

is connected to the black segment and the white side of the coil to the

white segment. The segments are insulated from each other. The two stationary

brushes are placed on opposite sides of the commutator and are so mounted

that each brush contacts each segment of the commutator as the latter revolves

simultaneously with the loop. The rotating parts of a dc generator (coil

and commutator) are called an armature.

The generation of an e.m.f. by the loop rotating in the magnetic field

is the same for both ac and dc generators, but the action of the commutator

produces a dc voltage.

This generation of a dc voltage is described as follows for the various

positions of the loop rotating in a magnetic field, with reference to figure

9-7. The loop in position A of figure 9-7 is rotating clockwise, but

no lines of force are cut by the coil sides and no e.m.f. is generated.

The black brush is shown coming into contact with the black segment of

the commutator, and the white brush is just coming into contact with the

white segment.

In position B of figure 9-7, the flux is being

cut at a maximum rate and the induced e.m.f. is maximum. At this time,

the black brush is contacting the black segment and the white brush is

contacting the white segment. The deflection of the meter is toward the

right, indicating the polarity of the output voltage.

At position C of figure 9-7, the loop has completed

180° of rotation. Again, no flux lines are being cut and the output

voltage is zero. The important condition to observe at position C is the

action of the segments and brushes. The black brush at the 180° angle

is contacting both black and white segments on one side of the commutator,

and the white brush is contacting both segments on the other side of the

commutator. After the loop rotates slightly past the 180° point, the

black brush is contacting only the white segment and the white brush is

contacting only the black segment.

Because of this switching of commutator elements, the black brush is

always in contact with the coil side moving downward, and the white brush

is always in contact with the coil side moving upward. Though the current

actually reverses its direction in the loop in exactly the same way as

in the ac generator, commutator action causes the current to flow always

in the same direction through the external circuit or meter.

A graph of one cycle of operation is shown in figure

9-7. The generation of the e.m.f. for positions A, B, and C is the

same as for the basic ac generator, but at position D, commutator action

reverses the current in the external circuit, and the second half cycle

has the same waveform as the first half cycle. The process of commutation

is sometimes called rectification, since rectification is the converting

of an ac voltage to a dc voltage.

At the instant that each brush is contacting two segments on the commutator

(positions A, C, and E in figure 9-7), a direct short

circuit is produced. If an e.m.f. were generated in the loop at this time,

a high current would flow in the circuit, causing an arc and thus damaging

the commutator. For this reason, the brushes must be placed in the exact

position where the short will occur when the generated e.m.f. is zero.

This position is called the neutral plane.

The voltage generated by the basic dc generator in figure

9-7 varies from zero to its maximum value twice for each revolution

of the loop. This variation of dc voltage is called "ripple," and may be

reduced by using more loops, or coils, as shown in A of figure 9-8.

As the number of loops is increased, the variation between maximum and

minimum values of voltage is reduced (B of figure 9-8),

and the output voltage of the generator approaches a steady dc value. In

A of figure 9-8 the number of commutator segments

is increased in direct proportion to the number of loops; that is, there

are two segments for one loop, four segments for two loops, and eight segments

for four loops.

The voltage induced in a single turn loop is small. Increasing the number

of loops does not increase the maximum value of generated voltage, but

increasing the number of turns in each loop will increase this value. Within

narrow limits, the output voltage of a dc generator is determined by the

product of the number of turns per loop, the total flux per pair of poles

in the machine, and the speed of rotation of the armature.

An ac generator, or alternator, and a dc generator are identical as

far as the method of generating voltage in the rotating loop is concerned.

However, if the current is taken from the loop by slip rings, it is an

alternating current, and the generator is called an ac generator, or alternator.

If the current is collected by a commutator, it is direct current, and

the generator is called a dc generator.

Construction Features of DC Generators

Generators used on aircraft may differ somewhat in design, since they

are made by various manufacturers. All, however, are of the same general

construction and operate similarly. The major parts, or assemblies, of

a dc generator are a field frame (or yoke), a rotating armature, and a

brush assembly. The parts of a typical aircraft generator are shown in

figure 9-9.

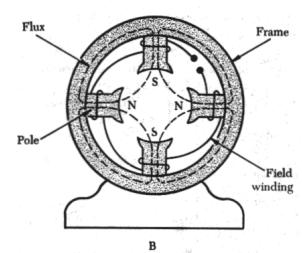

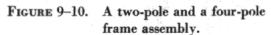

Field Frame

The field frame is also called the yoke, which is the foundation or

frame for the generator. The frame has two functions: It completes the

magnetic circuit between the poles and acts as a mechanical support for

the other parts of the generator. In A of figure 9-10, the frame for a

two pole generator is shown in a cross-sectional view. A four pole generator

frame is shown in B of figure 9-10.

In small generators, the frame is made of one piece of iron, but in

larger generators, it is usually made up of two parts bolted together.

The frame has high magnetic properties and, together with the pole pieces,

forms the major part of the magnetic circuit. The field poles, shown in

figure 9-10, are bolted to the inside of the frame and form a core on which

the field coil windings are mounted.

The poles are usually laminated to reduce eddy current losses and serve

the same purpose as the iron core of an electromagnet; that is, they concentrate

the lines of force produced by the field coils. The entire frame including

field poles, is made from high quality magnetic iron or sheet steel.

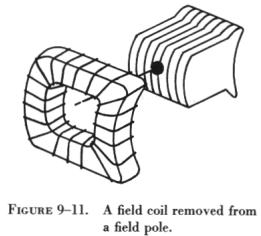

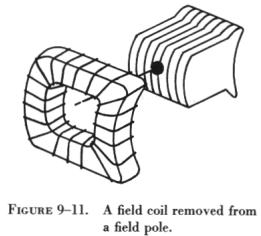

| A practical dc generator uses electromagnets instead of

permanent magnets. To produce a magnetic field of the necessary strength

with permanent magnets would greatly increase the physical size of the

generator.

The field coils are made up of many turns of insulated wire and are

usually wound on a form which fits over the iron core of the pole to which

it is securely fastened (figure 9-11). The exciting current, which is used

to produce the magnetic field and which flows through the field coils,

is obtained from an external source or from the generated dc of the machine.

No electrical connection exists between the windings of the field coils

and the pole pieces.

Most field coils are connected in such a manner that the poles show

alternate polarity. Since there is always one north pole for each south

pole, there must always be an even number of poles in any generator. |

|

Note that the pole pieces in figure 9-10 project

from the frame. Because air offers a great amount of reluctance to the

magnetic field, this design reduces the length of the air gap between the

poles and the rotating armature and increases the efficiency of the generator.

When the pole pieces are made to project as shown in figure

9-10, they are called salient poles.

Armature

The armature assembly consists of armature coils wound on an iron core,

a commutator, and associated mechanical parts. Mounted on a shaft, it rotates

through the magnetic field produced by the field coils. The core of the

armature acts as an iron conductor in the magnetic field and, for this

reason, is laminated to prevent the circulation of eddy currents.

There are two general kinds of armatures: the ring and the drum. Figure

9-12 shows a ring-type armature made up of an iron core, an eight section

winding, and an eight segment commutator. This kind of armature is rarely

used; most generators use the drum-type armature.

A drum-type armature (figure 9-13) has coils

placed in slots in the core, but there is no electrical connection between

the coils and core. The use of slots increases the mechanical safety of

the armature. Usually, the coils are held in place in the slots by means

of wooden or fiber wedges. The connections of the individual coils, called

coil ends, are brought out to individual segments on the commutator.

Commutators

Figure 9-14 shows a cross-sectional view of a

typical commutator. The commutator is located at the end of an armature

and consists of wedge shaped segments of hard drawn copper, insulated from

each other by thin sheets of mica. The segments are held in place by steel

V-rings or clamping flanges fitted with bolts. Rings of mica insulate the

segments from the flanges. The raised portion of each segment is called

a riser, and the leads from the armature coils are soldered to the risers.

When the segments have no risers, the leads are soldered to short slits

in the ends of the segments.

The brushes ride on the surface of the commutator, forming the electrical

contact between the armature coils and the external circuit. A flexible,

braided copper conductor, commonly called a pigtail, connects each brush

to the external circuit. The brushes, usually made of high grade carbon

and held in place by brush holders insulated from the frame, are free to

slide up and down in their holders in order to follow any irregularities

in the surface of the commutator. The brushes are usually adjustable so

that the pressure of the brushes on the commutator can be varied and the

position of the brushes with respect to the segments can be adjusted.

The constant making and breaking of connections to the coils in which

a voltage is being induced necessitates the use of material for brushes

which has a definite contact resistance. Also, this material must be such

that the friction between the commutator and the brush is low, to prevent

excessive wear. For these reasons, the material commonly used for brushes

is high grade carbon. The carbon must be soft enough to prevent undue wear

of the commutator and yet hard enough to provide reasonable brush life.

Since the contact resistance of carbon is fairly high, the brush must be

quite large to provide a large area of contact. The commutator surface

is highly polished to reduce friction as much as possible. Oil or grease

must never be used on a commutator, and extreme care must be used when

cleaning it to avoid marring or scratching the surface.