FLEXIBLEHOSE

FLEXIBLE HOSE

Flexible hose is used in aircraft plumbing to connect moving parts with

stationary parts in locations subject to vibration or where a great amount

of flexibility is needed. It can also serve as a connector in metal tubing

systems.

Synthetics

Synthetic materials most commonly used in the manufacture of flexible

hose are: Buna-N, Neoprene, Butyl and Teflon (trademark of DuPont Corp.).

Buna-N is a synthetic rubber compound which has excellent resistance to

petroleum products. Do not confuse with Buna-S. Do not use for phosphate

ester base hydraulic fluid (Skydrol). Neoprene is a synthetic rubber compound

which has an acetylene base. Its resistance to petroleum products is not

as good as Buna-N but has better abrasive resistance. Do not use for phosphate

ester base hydraulic fluid (Skydrol). Butyl is a synthetic rubber compound

made from petroleum raw materials. It is an excellent material to use with

phosphate ester based hydraulic fluid (Skydrol). Do not use with petroleum

products. Teflon is the DuPont trade name for tetrafluoroethylene resin.

It has a broad operating temperature range (-65° F to +450° F).

It is compatible with nearly every substance or agent used. It offers little

resistance to flow; sticky viscous materials will not adhere to it. It

has less volumetric expansion than rubber and the shelf and service life

is practically limitless.

Rubber Hose

Flexible rubber hose consists of a seamless synthetic rubber inner tube

covered with layers of cotton braid and wire braid, and an outer layer

of rubber impregnated cotton braid. This type of hose is suitable for use

in fuel, oil, coolant, and hydraulic systems. The types of hose are normally

classified by the amount of pressure they are designed to withstand under

normal operating conditions.

1. Low pressure, any pressure below 250 psi.

Fabric braid reinforcement.

2. Medium pressure, pressures up to 3,000 psi.

One wire braid reinforcement.

Smaller sizes carry pressure up to 3,000 psi.

Larger sizes carry pressure up to 1,500 psi.

3. High pressure (all sizes up to 3,000 psi operating pressures).

Identification markings consisting of lines, letters, and numbers are

printed on the hose. (See figure 5-2.) These code

markings show such information as hose size, manufacturer, date of manufacture,

and pressure and temperature limits. Code markings assist in replacing

a hose with one of the same specification or a recommended substitute.

Hose suitable for use with phosphate ester base, hydraulic fluid will be

marked "Skydrol ^R use". In some instances several types of hose may be

suitable for the same use. Therefore, in order to make the correct hose

selection, always refer to the maintenance or parts manual for the particular

airplane.

Teflon Hose

Teflon hose is a flexible hose designed to meet the requirements of

higher operating temperatures and pressures in present aircraft systems.

It can generally be used in the same manner as rubber hose. Teflon hose

is processed and extruded into tube shape to a desired size. It is covered

with stainless steel wire, which is braided over the tube for strength

and protection.

Teflon hose is unaffected by any known fuel, petroleum, or synthetic

base oils, alcohol, coolants, or solvents commonly used in aircraft. Although

it is highly resistant to vibration and fatigue, the principle advantage

of this hose is its operating strength.

Size Designation

The size of flexible hose is determined by its inside diameter. Sizes

are in one-sixteenth inch increments and are identical to corresponding

sizes of rigid tubing, with which it can be used.

Identification of Fluid Lines

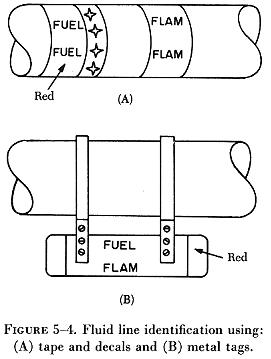

Fluid lines in aircraft are often identified by markers made up of color

codes, words, and geometric symbols. These markers identify each line's

function, content, and primary hazard, as well as the direction of fluid

flow. Figure 5-3 illustrates the various

| color codes and symbols used to designate the type of system

and its contents. In most instances, fluid lines are marked with 1 inch

tape or decals, as shown in figure 5-4 (A).

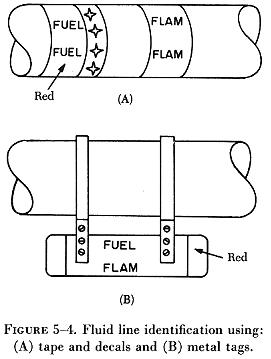

On lines 4 inches in diameter (or larger), lines in oily environment,

hot lines, and on some cold lines, steel tags may be used in place of tape

or decals, as shown in figure 5-4(B). Paint is used on lines in engine

compartments, where there is the possibility of tapes, decals, or tags

being drawn into the engine induction system.

In addition to the above mentioned markings, certain lines may be further

identified as to specific function within a system; for example, DRAIN,

VENT, PRESSURE, or RETURN.

Lines conveying fuel may be marked FLAM; lines containing toxic materials

are marked TOXIC in place of FLAM. Lines containing physically dangerous

materials, such as oxygen, nitrogen, or freon, are marked PHDAN.

The aircraft and engine manufacturers are responsible for the original

installation of identification markers, but the aviation mechanic is responsible

for their replacement when it becomes necessary. |

|

Generally, tapes and decals are placed on both ends of a line and at

least once in each compartment through which the line runs. In addition,

identification markers are placed immediately adjacent to each valve, regulator,

filter, or other accessory within a line. Where paint or tags are used,

location requirements are the same as for tapes and decals.