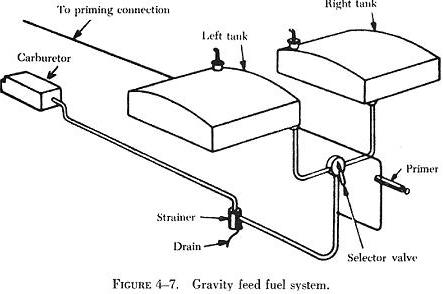

The simplest type of fuel system is the gravity feed, which is still

in use on many low powered airplanes. A gravity feed system is shown in

figure 4-7. The fuel tanks are mounted above the carburetor, with gravity

causing the fuel to flow from the tanks to the carburetor. A selector valve

is provided to stop the fuel flow or to select a particular tank in the

system from which to draw fuel. A strainer filters the fuel before it reaches

the carburetor. A drain is provided for removing water and sediment trapped

at the strainer. A primer furnishes the additional fuel required for engine

starting.