GRAPHSANDCHARTS

| GRAPHS AND CHARTS

Graphs and charts are pictorial presentations of data, equations, and

formulas. Through their use the relationship between two or more quantities

may be more clearly understood. Also, a person can see certain conditions

or relationships at a glance, while it would require considerable time

to obtain the same information from a written description. Graphs may be

used in a number of ways, such as representing a single equation or formula,

or they may be used to solve two equations for a common value.

Graphs and charts take many forms. A few of the more common forms are

called bar graphs, pictographs, broken line graphs, continuous curved line

graphs, and circle graphs. An example of each is shown in figure 1-20.

The most useful of these graphs in technical work is the continuous curved

line graph.

Interpreting/Reading

Interpreting or Reading Graphs and Charts |

|

|

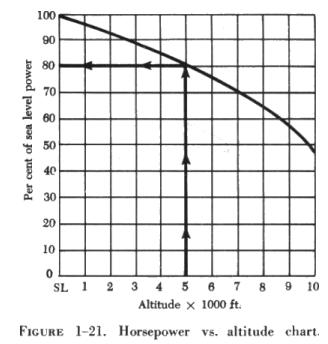

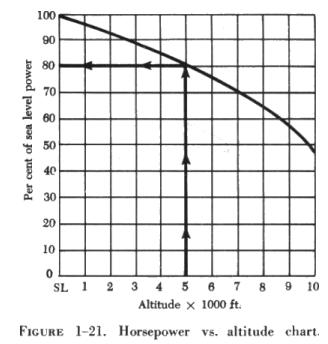

It is more important, from the mechanic's viewpoint, to be able to

read a graph properly than it is to draw one. The relationship between

the horsepower of a certain engine at sea level and at any altitude up

to 10,000 feet can be determined by use of the chart in figure 1-21. To

use this type of chart, simply find the point on the horizontal axis that

represents the desired altitude; move upward along this line to the point

where it intersects the curved line; then move to the left, reading the

percent of sea level horsepower available on the vertical axis.

EXAMPLE

What percent of the sea level horsepower is available at an altitude

of 5,000 feet?

FIRST: Locate the point on the horizontal axis that represents 5,000

feet. Move upward to the point where the line intersects the curved line. |

NEXT: Move to the left, reading the percent of sea level horsepower

available at 5,000 feet. The available horsepower is 80%.

Nomograms

It is often necessary to make calculations using the same formula, but

using different sets of values for the variables. It is possible to obtain

a solution by use of a slide rule or by preparing a table giving the solution

of the formula resulting from successive changes of each variable. However,

in the case of formulas involving several mathematical operations, the

labor entailed would usually be very great.

It is possible to avoid all this labor by using a diagram representing

the formula, in which each variable is represented by one or more graduated

lines. From this diagram, the solution of the formula for any given variable

may be read by means of an index line. A diagram of this type is known

as a nomogram.

Much of the information needed to solve aeronautical problems will be

presented in nomogram form. Instruction manuals for the various aircraft

contain numerous nomograms, many of which appear quite complex.

Many of the presentations will possess several curves on the same coordinate

axis, each curve drawn for different constants in the equation. In the

latter case, it is essential to select the proper curve for the desired

conditions.

Again, as with the simpler graphs, it is more important for the mechanic

to be able to read nomograms than it is to draw them.

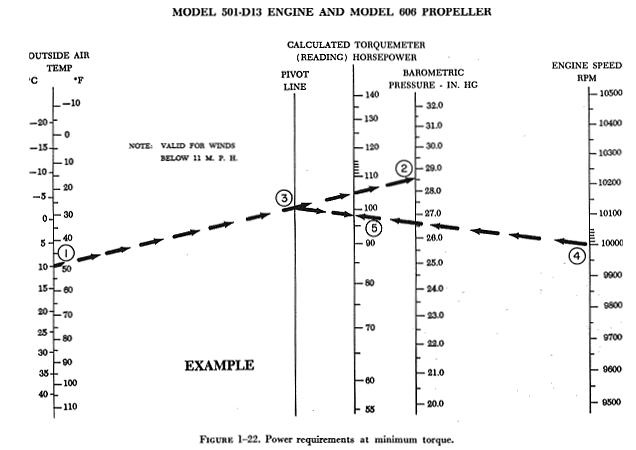

The following example is taken from the maintenance manual for the Allison

501-D13 turboprop engine. A nomogram (figure 1-22) is used to determine

the power requirements when the engine is operating at minimum torque.

The OAT (outside air temperature), station barometric pressure, and engine

rpm are three factors that must be known to use this particular nomogram.

EXAMPLE

Determine the calculated horsepower of a certain engine, using the nomogram

in figure 1-22. Assume that the OAT is 10° C, the barometric pressure

is 28.5 in Hg, and the engine is operating at 10,000 rpm.

FIRST: Locate the reference points on the OAT scale and on the barometric

pressure scale that correspond to the given temperature and pressure readings.

These are identified as 1 and 2 respectively, on the chart. With the aid

of a straightedge, connect these two points and establish point 3 on the

pivot line.

NEXT: Locate the engine speed, identified as 4 on the engine speed rpm

scale. Using a straightedge, connect points 3 and 4 and establish point

5 on the calculated horsepower scale. The calculated horsepower is read

at point 5. The calculated horsepower is 98%.