For corrosion prevention, aluminum alloy lines and fittings are usually anodized. Steel lines and fittings, if not stainless steel, are plated to prevent rusting or corroding. Brass and steel fittings are usually cadmium plated, although some may come plated with nickel, chromium, or tin.

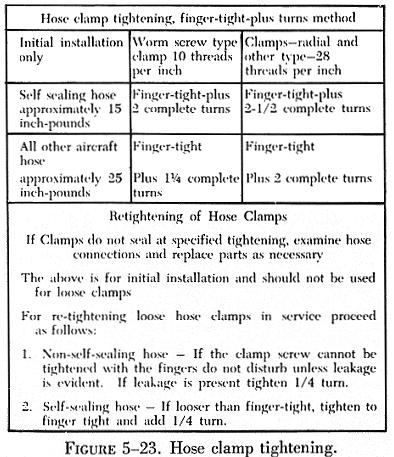

To ensure proper sealing of hose connections and to prevent breaking hose clamps or damaging the hose, follow the hose clamp tightening instructions carefully. When available, use the hose clamp torque limiting wrench. These wrenches are available in calibrations of 15 and 25 inch-pounds. In the absence of torque limiting wrenches, the fingertight plus turns method should be followed.

Because of the variations in hose clamp design and hose structure, the values given in figure 5-23 are approximate. Therefore, use good judgment when tightening hose clamps by this method. Since hose connections are subject to "cold flow" or a setting process, a followup tightening check should be made for several days after installation.