READINGDRAWINGS

READING DRAWINGS

A drawing cannot be read all at once any more than a whole page of print

can be read at a glance. Both must be read a line at a time. To read a

drawing effectively, follow a systematic procedure.

Upon opening a drawing, read the drawing number and the description

of the article. Next, check the model affected, the latest change letter,

and the next assembly listed. Having determined that the drawing is the

correct one, proceed to read the illustration(s).

In reading a multiview drawing, first get a general idea of the shape

of the object by scanning all the views; then select one view for a more

careful study. By referring back and forth to the adjacent view, it will

be possible to determine what each line represents.

| Each line on a view represents a change in the direction

of a surface, but another view must be consulted to determine what the

change is. For example, a circle on one view may mean either a hole or

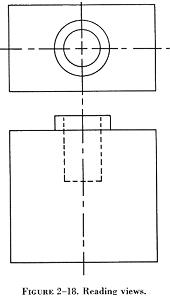

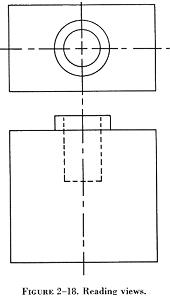

a protruding boss, as in the top view of the object in figure 2-18. Looking

at the top view, we see two circles; however, the other view must be consulted

to determine what each circle represents.

A glance at the other view tells us that the smaller circle represents

a hole, and the larger circle represents a protruding boss. In the same

way, the top view must be consulted to determine the shape of the hole

and the protruding boss.

It can be seen from this example that one cannot read a print by looking

at a single view, when more than one view is given. Two views will not

always describe an object, and when three views are given, all three must

be consulted to be sure the shape has been read correctly. |

|

After determining the shape of an object, determine its size. Information

on dimensions and tolerances is given so that certain design requirements

may be met. Dimensions are indicated by figures either with or without

the inch mark. If no inch mark is used, the dimension is in inches. It

is customary to give part dimensions and an overall dimension that gives

the greatest length of the part. If the overall dimension is missing, it

can be determined by adding the separate part dimensions.

Drawings may be dimensioned in decimals or fractions. This is especially

true in reference to tolerances. Many firms, instead of using plus and

minus signs for tolerances, give the complete dimension for both tolerances.

For example if a dimension is 2 inches with a plus or minus tolerance of

0.01, the drawing would show the total dimensions as:

2.01

1.99

A print tolerance (usually found in the title block) is a general tolerance

that can be applied to parts where the dimensions are noncritical. Where

a tolerance is not shown on a dimension line, the print tolerance applies.

To complete the reading of a drawing, read the general notes and the

contents of the material block, check and find the various changes incorporated,

and read the special information given in or near views and sections.