Temperature

The temperatures used for solution heat treating vary with different alloys and range from 825° F to 980° F. As a rule, they must be controlled within a very narrow range (plus or minus 10°) to obtain specified properties.

If the temperature is too low, maximum strength will not be obtained. When excessive temperatures are used, there is danger of melting the low melting constituents of some alloys with consequent lowering of the physical properties of the alloy. Even if melting does not occur, the use of higher than recommended temperatures promotes discoloration and increases quenching strains.

Time at Temperature

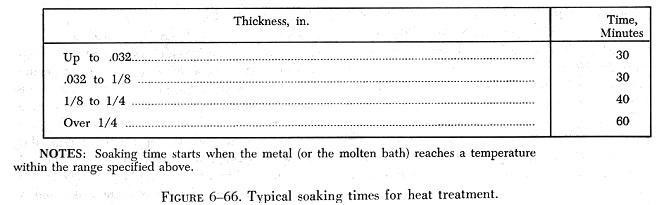

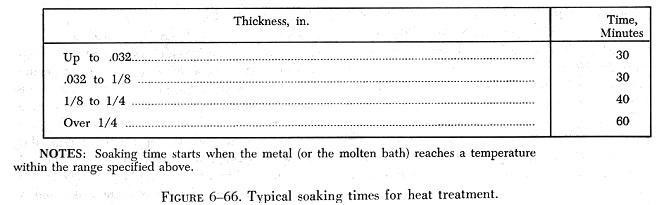

The time at temperature, referred to as soaking time, is measured from the time the coldest metal reaches the minimum limit of the desired temperature range. The soaking time varies, depending upon the alloy and thickness, from 10 minutes for thin sheets to approximately 12 hours for heavy forgings. For the heavy sections, the nominal soaking time is approximately 1 hour for each inch of cross-sectional thickness (see figure 6-66).

The soaking time is chosen so that it will be the minimum necessary to develop the required physical properties. The effect of an abbreviated soaking time is obvious. An excessive soaking period aggravates high temperature oxidation. With clad material, prolonged heating results in excessive diffusion of copper and other soluble constituents into the protective cladding and may defeat the purpose of cladding.

Quenching

After the soluble constituents are in solid solution, the material is quenched to prevent or retard immediate reprecipitation. Three distinct quenching methods are employed. The one to be used in any particular instance depends upon the part, the alloy, and the properties desired.

Cold Water Quenching

Parts produced from sheet, extrusions, tubing, small forgings, and similar type material are generally quenched in a cold water bath. The temperature of the water before quenching should not exceed 85° F.

A sufficient quantity of water should be used to keep the temperature rise under 20° F. Such a drastic quench ensures maximum resistance to corrosion. This is particularly important when working with such alloys as 2017, 2024, and 7075. This is the reason a drastic quench is preferred, even though a slower quench may produce the required mechanical properties.

Hot Water Quenching

Large forgings and heavy sections can be quenched in hot or boiling water. This type of quench minimizes distortion and alleviates cracking which may be produced by the unequal temperatures obtained during the quench. The use of a hot water quench is permitted with these parts because the temperature of the quench water does not critically affect the resistance to corrosion of the forging alloys. In addition, the resistance to corrosion of heavy sections is not as critical a factor as for thin sections.

Spray Quenching

High velocity water sprays are useful for parts formed from clad sheet and for large sections of almost all alloys. This type of quench also minimizes distortion and alleviates quench cracking. However, many specifications forbid the use of spray quenching for bare 2017 and 2024 sheet materials because of the effect on their resistance to corrosion.

Lag Between Soaking and Quenching

The time interval between the removal of the material from the furnace and quenching is critical for some alloys and should be held to a minimum. When solution heat treating 2017 or 2024 sheet material, the elapsed time must not exceed 10 seconds. The allowable time for heavy sections may be slightly greater.

Allowing the metal to cool slightly before quenching promotes reprecipitation from the solid solution. The precipitation occurs along grain boundaries and in certain slip planes causing poorer formability. In the case of 2017, 2024, and 7075 alloys, their resistance to intergranular corrosion is adversely affected.

Reheat Treatment

The treatment of material which has been previously heat treated is considered a reheat treatment. The unclad heat treatable alloys can be solution heat treated repeatedly without harmful effects.

The number of solution heat treatments allowed for clad sheet is limited due to increased diffusion of core and cladding with each reheating. Existing specifications allow one to three reheat treatments of clad sheet depending upon cladding thickness.

Straightening After Solution Heat Treatment

Some warping occurs during solution heat treatment, producing kinks, buckles, waves, and twists. These imperfections are generally removed by straightening and flattening operations.

Where the straightening operations produce an appreciable increase in the tensile and yield strengths and a slight decrease in the percent of elongation, the material is designated -T3 temper. When the above values are not materially affected, the material is designated -T4 temper.