SPECIALPURPOSEBOLTS

SPECIAL PURPOSE BOLTS

Bolts designed for a particular application or use are classified as

special purpose bolts. Clevis bolts, eyebolts, Jo-bolts, and lock bolts

are special purpose bolts.

Clevis Bolts

The head of a clevis bolt is round and is either slotted to receive

a common screwdriver or recessed to receive a crosspoint screwdriver. This

type of bolt is used only where shear loads occur and never in tension.

It is often inserted as a mechanical pin in a control system.

Eyebolt

This type of special purpose bolt is used where external tension loads

are to be applied. The eye is designed for the attachment of such devices

as the fork of a turnbuckle, a clevis, or a cable shackle. The threaded

end may or may not be drilled for safetying.

Jo-Bolt

Jo-bolt is a trade name for an internally threaded three piece rivet.

The Jo-bolt consists of three parts - a threaded steel alloy bolt, a threaded

steel nut, and an expandable stainless steel sleeve. The parts are factory

preassembled. As the Jo-bolt is installed, the bolt is turned while the

nut is held. This causes the sleeve to expand over the end of the nut,

forming the blind head and clamping against the work. When driving is complete,

a portion of the bolt breaks off. The high shear and tensile strength of

the Jo-bolt makes it suitable for use in cases of high stresses where some

of the other blind fasteners would not be practical. Jo-bolts are often

a part of the permanent structure of late model aircraft. They are used

in areas which are not often subjected to replacement or servicing. (Because

it is a three part fastener, it should not be used where any part, in becoming

loose, could be drawn into the engine air intake.) Other advantages of

using Jo-bolts are their excellent resistance to vibration, weight saving,

and fast installation by one person.

Presently, Jo-bolts are available in four diameters: The 200 series,

approximately 3/16 inch in diameter; the 260 series, approximately 1/4

inch in diameter; the 312 series, approximately 5/16 inch in diameter;

and the 375 series, approximately 3/8 inch in diameter. Jo-bolts are available

in three head styles which are: F (flush), P (hex head), and FA (flush

millable).

Lockbolts

| The lockbolt combines the features of a high strength bolt

and rivet, but it has advantages over both. The lockbolt is generally used

in wing splice fittings, landing gear fittings, fuel cell fittings, longerons,

beams, skin splice plates, and other major structural attachments. It is

more easily and quickly installed than the conventional rivet or bolt and

eliminates the use of lockwashers, cotter pins, and special nuts. Like

the rivet, the lockbolt requires a pneumatic hammer or "pull gun" for installation;

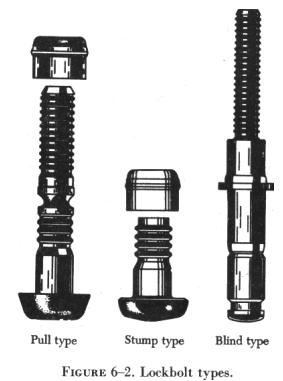

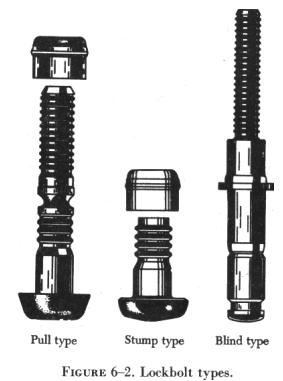

when installed, it is rigidly and permanently locked in place. Three types

of lockbolts are commonly used, the pull type, the stump type, and the

blind type. (See figure 6-2.)

Pull type. Pull-type lockbolts are used mainly in aircraft primary and

secondary structures. They are installed very rapidly and have approximately

one-half the weight of equivalent AN steel bolts and nuts. A special pneumatic

"pull gun" is required to install this type of lockbolt. Installation can

be accomplished by one person since bucking is not required.

Stump type. Stump-type lockbolts, although they do not have the extended

stem with pull grooves, are companion fasteners to pull-type lockbolts.

They are used primarily where clearance will not permit installation of

the pull-type lockbolt. A standard pneumatic riveting hammer (with a hammer

set attached for swaging the collar into the pin locking grooves) and a

bucking bar are tools necessary for the installation of stump-type lockbolts. |

|

Blind type. Blind-type lockbolts come as complete units or assemblies.

They have exceptional strength and sheet pull together characteristics.

Blind lockbolts are used where only one side of the work is accessible

and, generally, where it is difficult to drive a conventional rivet. This

type of lockbolt is installed in the same manner as the pull-type lockbolt.

Common features. Common features of the three types of lockbolts are

the annular locking grooves on the pin and the locking collar which is

swaged into the pin's lock grooves to lock the pin in tension. The pins

of the pull and blind-type lockbolts are extended for pull installation.

The extension is provided with pulling grooves and a tension breakoff groove.

Composition. The pins of pull and stump-type lockbolts are made of heat

treated alloy steel or high strength aluminum alloy. Companion collars

are made of aluminum alloy or mild steel. The blind lockbolt consists of

a heat treated alloy steel pin, blind sleeve and filler sleeve, mild steel

collar, and carbon steel washer.

Substitution. Alloy steel lockbolts may be used to replace steel hishear

rivets, solid steel rivets, or AN bolts of the same diameter and head type.

Aluminum alloy lockbolts may be used to replace solid aluminum alloy rivets

of the same diameter and head type. Steel and aluminum alloy lockbolts

may also be used to replace steel and 2024T aluminum alloy bolts, respectively,

of the same diameter. Blind lockbolts may be used to replace solid aluminum

alloy rivets, stainless steel rivets, or all blind rivets of the same diameter.

Numbering system. The numbering systems for the various types of lockbolts

are explained by the following breakouts (see figure

6-4).

Grip Range. The bolt grip range required for any application should

be determined by measuring the thickness of the material with a hook scale

inserted through the hole. Once this measurement is determined the correct

grip range can be selected by referring to the charts provided by the rivet

manufacturer. Examples of grip range charts are shown in figure

6-3 and figure 6-5.

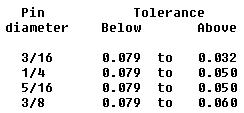

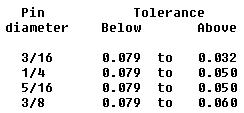

When installed, the lockbolt collar should be swaged substantially throughout

the complete length of the collar. The tolerance of the broken end of the

pin relative to the top of the collar must be within the following dimensions:

When removal of a lockbolt becomes necessary, remove the collar by splitting

it axially with a sharp, cold chisel. Be careful not to break out or deform

the hole. The use of a backup bar on the opposite side of the collar being

split is recommended. The pin may then be driven out with a drift punch.