Use bonded clamps to secure metal hydraulic, fuel, and oil lines in place. Unbonded clamps should be used only for securing wiring. Remove any paint or anodizing from the portion of the tube at the bonding clamp location. Make certain that clamps are of the correct size. Clamps or supporting clips smaller than the outside diameter of the hose may restrict the flow of fluid through the hose.

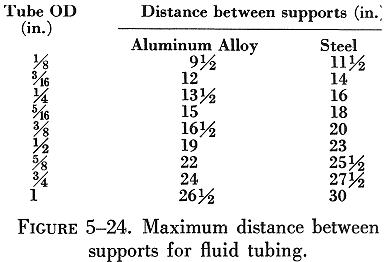

All plumbing lines must be secured at specified intervals. The maximum distance between supports for rigid fluid tubing is shown in figure 5-24.

.

.