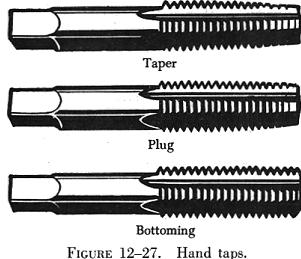

Hand taps are usually provided in sets of three taps for each diameter and thread series. Each set contains a taper tap, a plug tap, and a bottoming tap. The taps in a set are identical in diameter and cross section; the only difference is the amount of taper (see figure 12-27).

The taper tap is used to begin the tapping process, because it is tapered back for 6 to 7 threads. This tap cuts a complete thread when it is cutting above the taper. It is the only tap needed when tapping holes that extend through thin sections. The plug tap supplements the taper tap for tapping holes in thick stock.