TUBEFORMINGPROCESSES

TUBE FORMING PROCESSES

Damaged tubing and fluid lines should be replaced with new parts whenever

possible. Sometimes replacement is impractical and repair is necessary.

Scratches, abrasions, and minor corrosion on the outside of fluid lines

may be considered negligible and can be smoothed out with a burnishing

tool or aluminum wool. Limitations on the amount of damage that can be

repaired in this manner are discussed later in this chapter under "Repair

of Metal Tube Lines." If a fluid line assembly is to be replaced, the fittings

can often be salvaged; then the repair will involve only tube forming and

replacement. Tube forming consists of four processes: (1) Cutting, (2)

bending, (3) flaring, and (4) beading. If the tubing is small and of soft

material, the assembly can be formed by hand bending during installation.

If the tubing is 1/4 inch diameter, or larger, hand bending without the

aid of tools is impractical.

Tube Cutting

| When cutting tubing, it is important to produce a square end, free

of burrs. Tubing may be cut with a tube cutter or a hacksaw. The cutter

can be used with any soft metal tubing, such as copper, aluminum, or aluminum

alloy. Correct use of the tube cutter is shown in figure 5-10.

A new piece of tubing should be cut approximately 10 percent longer

than the tube to be replaced to provide for minor variations in bending.

Place the tubing in the cutting tool, with the cutting wheel at the point

where the cut is to be made. Rotate the cutter around the tubing, applying

a light pressure to the cutting wheel by intermittently twisting the thumbscrew.

Too much pressure on the cutting wheel at one time could deform the tubing

or cause excessive burring. After cutting the tubing, carefully remove

any burrs from inside and outside the tube. Use a knife or the burring

edge attached to the tube cutter. |

|

When performing the deburring operation use extreme care that the wall

thickness of the end of the tubing is not reduced or fractured. Very slight

damage of this type can lead to fractured flares or defective flares which

will not seal properly. A fine tooth file can be used to file the end square

and smooth.

If a tube cutter is not available, or if tubing of hard material is

to be cut, use a fine tooth hacksaw, preferably one having 32 teeth per

inch. The use of a saw will decrease the amount of work hardening of the

tubing during the cutting operation. After sawing, file the end of the

tube square and smooth, removing all burrs.

| An easy way to hold small diameter tubing, when cutting

it, is to place the tube in a combination flaring tool and clamp the tool

in a vise. Make the cut about one-half inch from the flaring tool. This

procedure keeps sawing vibrations to a minimum and prevents damage to the

tubing if it is accidentally hit with the hacksaw frame or file handle

while cutting. Be sure all filings and cuttings are removed from the tube.

Tube Bending

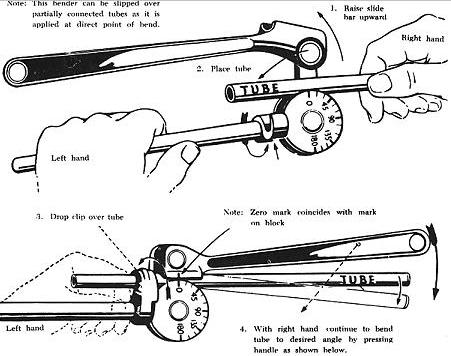

The objective in tube bending is to obtain a smooth bend without flattening

the tube. Tubing under one-fourth inch in diameter usually can be bent

without the use of a bending tool. For larger sizes, a hand tube bender

similar to that shown in figure 5-11 is usually used.

|

|

| To bend tubing with the hand tube bender, insert the tubing by raising

the slide bar handle as far as it will go. Adjust the handle so that the

full length of the groove in the slide bar is in contact with the tubing.

The zero mark on the radius block and the mark on the slide bar must align.

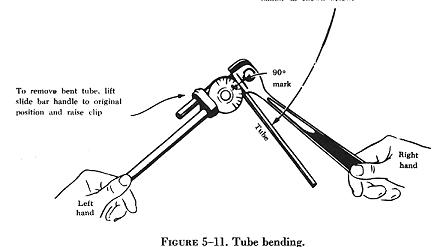

Make the bend by rotating the handle until the desired angle of bend is

obtained, as indicated on the radius block. |

|

Bend the tubing carefully to avoid excessive flattening, kinking, or

wrinkling. A small amount of flattening in bends is acceptable, but the

small diameter of the flattened portion must not be less than 75 percent

of the original outside diameter. Tubing with flattened, wrinkled, or irregular

bends should not be installed. Wrinkled bends usually result from trying

to bend thin wall tubing without using a tube bender. Examples of correct

and incorrect tubing bends are shown in figure 5-12.

Tube bending machines for all types of tubing are generally used in

repair stations and large maintenance shops. With such equipment, proper

bends can be made on large diameter tubing and on tubing made from hard

material. The production tube bender is an example of this type of machine.

The ordinary production tube bender will accommodate tubing ranging

from 1/2 inch to 1 1/2 inch outside diameter. Benders for larger sizes

are available, and the principle of their operation is similar to that

of the hand tube bender. The radius blocks are so constructed that the

radius of bend will vary with the tubing diameter. The radius of bend is

usually stamped on the block.

When hand or production tube benders are not available or are not suitable

for a particular bending operation, a filler of metallic composition or

of dry sand may be used to facilitate bending. When using this method,

cut the tube slightly longer than is required. The extra length is for

inserting a plug (which may be wooden) in each end.

After plugging one end, fill and pack the tube with fine, dry sand and

plug tightly. Both plugs must be tight so they will not be forced out when

the bend is made. The tube can also be closed by flattening the ends or

by soldering metal disks in them. After the ends are closed, bend the tubing

over a forming block shaped to the specified radius.

In a modified version of the filler method, a fusible alloy is used

instead of sand. In this method, the tube is filled under hot water with

a fusible alloy that melts at 160° F. The alloy filled tubing is then

removed from the water, allowed to cool, and bent slowly by hand around

a forming block or with a tube bender. After the bend is made, the alloy

is again melted under hot water and removed from the tubing.

When using either filler method, make certain that all particles of

the filler are removed so that none will be carried into the system in

which the tubing is installed. Store the fusible alloy filler where it

will be free from dust or dirt.

It can be remelted and reused as often as desired. Never heat this filler

in any other than the prescribed method, as the alloy will stick to the

inside of the tubing, making them both unusable.

Tube Flaring

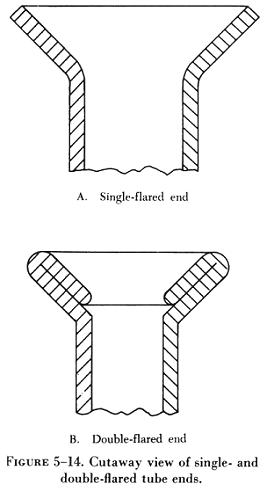

Two kinds of flares are generally used in aircraft plumbing systems,

the single flare and the double flare. Flares are frequently subjected

to extremely high pressures; therefore, the flare on the tubing must be

properly shaped or the connection will leak or fail.

A flare made too small produces a weak joint, which may leak or pull

apart; if made too large it interferes with the proper engagement of the

screw thread on the fitting and will cause leakage. A crooked flare is

the result of the tubing not being cut squarely. If a flare is not made

properly, flaws cannot be corrected by applying additional torque when

tightening the fitting. The flare and tubing must be free from cracks,

dents, nicks, scratches, or any other defects.

The flaring tool used for aircraft tubing has male and female dies ground

to produce a flare of 35° to 37°. Under no circumstances is it

permissible to use an automotive type flaring tool which produces a flare

of 45°.

Single Flare

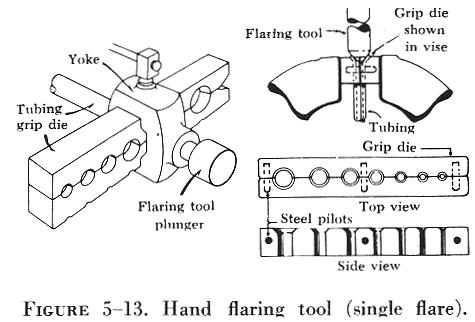

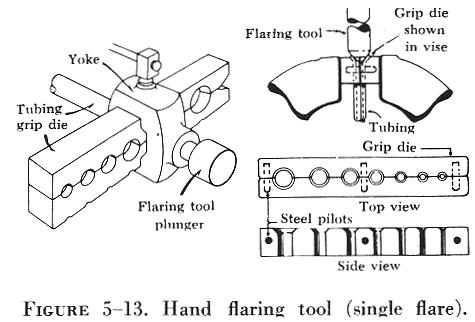

A hand flaring tool similar to that shown in figure 5-13 is used for

flaring tubing. The tool consists of a flaring block or grip die, a yoke,

and a flaring pin. The flaring block is a hinged double bar with holes

corresponding to various sizes of tubing. These holes are countersunk on

one end to form the outside support against which the flare is formed.

The yoke is used to center the flaring pin over the end of the tube to

be flared.

To prepare a tube for flaring, cut the tube squarely and remove all

burrs. Slip the fitting nut and sleeve on the tube and place the tube in

the proper size hole in the flaring tool. Center the plunger or flaring

pin over the end of the tube. Then project the end of the tubing slightly

from the top of the flaring tool, about the thickness of a dime, and tighten

the clamp bar securely to prevent slippage.

Make the flare by striking the plunger several light blows with a lightweight

hammer or mallet. Turn the plunger a half turn after each blow and be sure

it seats properly before removing the tube from the flaring tool. Check

the flare by sliding the sleeve into position over the flare. The outside

diameter of the flare should extend approximately one-sixteenth inch beyond

the end of the sleeve, but should not be larger than the major outside

diameter of the sleeve.

| Double Flare

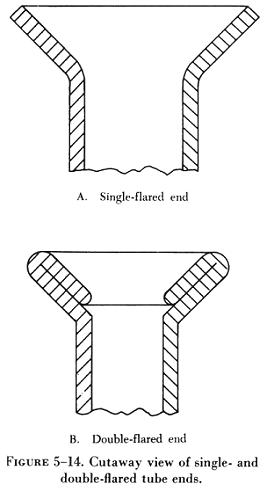

A double flare should be used on 5052-O and 6061-T aluminum alloy tubing

for all sizes from 1/8 to 3/8 inch outside diameter. This is necessary

to prevent cutting off the flare and failure of the tube assembly under

operating pressures. Double flaring is not necessary on steel tubing. See

figure 5-14 for an illustration of single and double flared tubing. The

double flare is smoother and more concentric than the single flare and,

therefore, seals better. It is also more resistant to the shearing effect

of torque.

To make the double flare, separate the clamp blocks of the double flaring

tool and insert and clamp the tubing with the burred end flush with the

top of the clamp. Insert the starting pin into the flaring pin guide and

strike the pin sharply with a hammer until the shoulder of the pin stops

against the clamp blocks. Remove the starting pin and insert the finishing

pin; hammer it until its shoulder rests on the clamp block.

Beading

Tubing may be beaded with a hand beading tool, with machine beading

rolls, or with grip dies. The method to be used depends on the diameter

and wall thickness of the tube and the material from which it was made.

The hand beading tool is used with tubing having 1/4 to 1 inch outside

diameter. The bead is formed by using the beader frame with the proper

rollers attached. The inside and outside of the tube is lubricated with

light oil to reduce the friction between the rollers during beading. The

sizes, marked in sixteenths of an inch on the rollers, are for the outside

diameter of the tubing that can be beaded with the rollers. |

|

Separate rollers are required for the inside of each tubing size, and

care must be taken to use the correct parts when beading. The hand beading

tool works somewhat like the tube cutter in that the roller is screwed

down intermittently while rotating the beading tool around the tubing.

In addition, a small vise (tube holder) is furnished with the kit.

Other methods and types of beading tools and machines are available,

but the hand beading tool is used most often. As a rule, beading machines

are limited to use with large diameter tubing, over 1 15/16 inch, unless

special rollers are supplied. The grip die method of beading is confined

to small tubing.

Flareless Tube Assemblies

Although the use of flareless tube fittings eliminates all tube flaring,

another operation, referred to as presetting, is necessary prior to installation

of a new flareless tube assembly. Figure 5-15 (steps

1, 2, and 3) illustrates the presetting operation, which is performed as

follows:

(a) Cut the tube to the correct length, with the ends perfectly square.

Deburr the inside and outside of the tube. Slip the nut, then the sleeve,

over the tube (step 1).

(b) Lubricate the threads of the fitting and nut with hydraulic fluid.

Place the fitting in a vise (step 2), and hold the tubing firmly and squarely

on the seat in the fitting. (Tube must bottom firmly in the fitting.) Tighten

the nut until the cutting edge of the sleeve grips the tube. This point

is determined by slowly turning the tube back and forth while tightening

the nut. When the tube no longer turns, the nut is ready for final tightening.

(c) Final tightening depends upon the tubing. For aluminum alloy tubing

up to and including 1/2 inch outside diameter, tighten the nut from one

to one and one-sixth turns. For steel tubing and aluminum alloy tubing

over 1/2 inch outside diameter, tighten from one and one-sixth to one and

one-half turns.

After presetting the sleeve, disconnect the tubing from the fitting

and check the following points

(a) The tube should extend 3/32 to 1/8 inch beyond the sleeve pilot;

otherwise blowoff may occur.

(b) The sleeve pilot should contact the tube or have a maximum clearance

of 0.005 inch for aluminum alloy tubing or 0.015 inch for steel tubing.

(c) A slight collapse of the tube at the sleeve cut is permissible.

No movement of the sleeve pilot, except rotation, is permissible.