Aircraft

Aircraft Engines

Since the engine develops the power to give the airplane its forward

motion, thus enabling it to fly, the pilot should have a basic knowledge

of how an engine works, and how to control its power.

The engine is commonly referred to as the "powerplant." Not only does

it provide power to propel the airplane, but it powers the units which

furnish electrical, hydraulic, and pneumatic energy for operation of electric

motors, pumps, controls, lights, radio, instruments, retractable landing

gear, and flaps. In many cases the engine also provides heat for crewmembers'

and passengers' comfort and for deicing equipment. In view of these varied

functions it is properly referred to as an "engine" or "powerplant" rather

than as a "motor."

The study of the powerplant begins with the definition of the term "internal

combustion engine." Internal combustion is the process by which a mixture

of fuel and oxygen is burned in a chamber from which the power can be taken

directly. This type of combustion can be contrasted to external combustion,

such as occurs in a steam engine, in which water is heated in one chamber

and transferred as steam to another chamber for transmission of its power.

The word "engine" therefore, is interpreted as meaning a machine in which

heat energy (released from burning gases) is transformed into mechanical

energy.

Two types of aircraft engines are in common use today. One type, used

so widely in the typical training airplanes, is known as the reciprocating

engine. In this type, pressures from burning and expanding gases cause

a piston to move up and down in an enclosed cylinder. This reciprocating

motion of the piston is transferred through a connecting rod into rotary

motion by a crankshaft, splined or geared to a propeller. In the second

type, the turbine jet engine generally used in military, airline, and many

corporate type airplanes, the continuous burning, expansion, and exhausting

of gases in one direction pushes the engine, and therefore the airplane,

in the opposite direction. Because the latter type engine is found only

in airplanes with very high performance characteristics, it will not be

dealt with in this handbook.

Reciprocating engines can be further classified as to the manner in

which the fuel is introduced into the cylinder. In training type airplanes

the usual method is by carburetion, a process of atomizing, vaporizing,

and mixing gasoline with air in a unit called a carburetor, before the

mixture enters the engine's cylinders. The mixture of gasoline and air

is then drawn into each of the cylinders by the up and down moving pistons,

or is forced under pressure into the cylinders by a blower or supercharger.

The other method of supplying the combustible fuel is by fuel injection,

whereby the gasoline is injected under pressure by a pump directly into

the cylinders where it vaporizes and mixes with air. The fuel/air mixture

is then fired (ignited) by timed electric ignition.

| Only the simplest reciprocating type of engine and its

operating principles are considered appropriate to the purpose of this

handbook. For ease of description, the text speaks of "up and down" movements

of the piston, but the same principles apply to engines which have the

cylinders arranged horizontally or radially around the crankshaft.

The propeller, which uses the engine power to produce thrust, is discussed

later in this chapter as a separate unit or accessory.

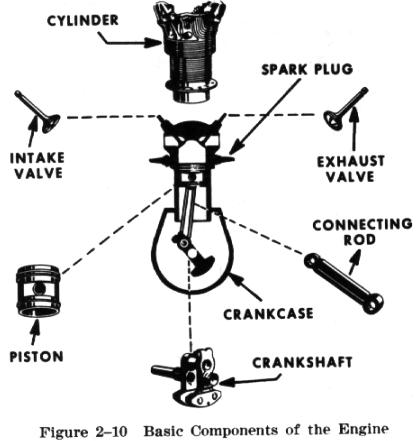

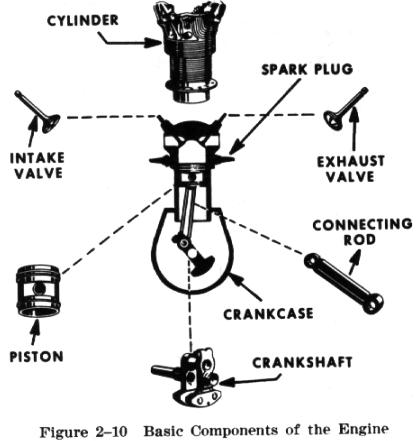

The basic parts of a reciprocating engine are the crankcase, cylinders,

pistons, connecting rods, valves, spark plugs, and crankshaft (Fig. 2-10).

In the head or top of each cylinder are two valves and two spark plugs.

One of these valves opens and closes a passage leading from the carburetor

(or induction manifold) and is called the intake valve. The other opens

and closes a passage leading to the outside atmosphere (or exhaust manifold)

and is called the exhaust valve. Inside each cylinder is a movable piston

which is attached to a crankshaft by means of a connecting rod. When the

rapidly expanding gases (resulting from the heat of combustion of the fuel

ignited by spark plugs) push the piston down within the cylinder, it causes

the crankshaft to rotate. At the same time, pistons in the other cylinders

and attached to the same crankshaft are moved within their individual cylinders

by the rotation of the crankshaft and go through the exact same sequence

or cycle. |

|