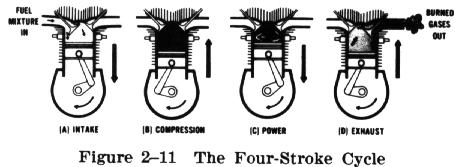

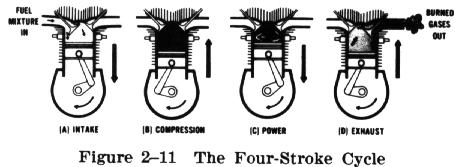

| The series of operations or events through which each cylinder of a reciprocating engine must pass in order to operate continuously and deliver power is called an engine cycle. The events that occur are intake, compression, power, and exhaust (Fig. 2-11). This cycle requires four strokes of the piston, two up and two down. Ignition of the fuel/air mixture at the end of the compression stroke adds a fifth event; consequently, the cycle of events is known as the four stroke, five event cycle principle. |  |

As the piston moves downward on the intake stroke, the intake valve

is open and the exhaust valve is closed. The piston draws air from the

air intake through the carburetor, past the intake valve into the cylinder

or combustion chamber. As the air passes through the carburetor, gasoline

is introduced into the air flow, forming a combustible mixture. The quantity

or weight of the fuel/air mixture is governed by the throttle setting selected

by the pilot to regulate the amount of power the engine develops.

When the piston approaches the lower limit of its downward

stroke, the intake valve closes and traps the gaseous mixture of air and

fuel within the combustion chamber. Next, because both valves are closed

as the piston moves upward, the fuel/air mixture is highly compressed between

the piston and cylinder head when the upmost position (top dead center)

is reached. This is the compression stroke.

At the appropriate instant, an electric spark passes across the electrodes or terminals of each spark plug in the cylinder and ignites the mixture. This third event, ignition takes place just slightly before the piston reaches top dead center of the compression stroke. As the mixture burns, temperature and pressure within the cylinder rise rapidly. The gaseous mixture, expanding as it burns, forces the piston downward and causes it to deliver mechanical energy to the crankshaft. This is the power stroke. Both valves are closed at the start of this stroke.

The energy delivered to the crankshaft during the power stroke causes the crankshaft to rotate on its bearing. Continued rotation causes the piston to move upward again. The exhaust valve, which opened during the latter part of the downward power stroke, remains open during the subsequent upward stroke and allows the burned gases to be ejected from the combustion chamber or cylinders. This stroke is the exhaust stroke. On the next stroke of the piston, air is again drawn into the cylinder; hence the four stroke, five event cycle begins again and is repeated as long as the engine is operated.

Aircraft engines are multicylinder, having four or more cylinders. Each individual cylinder has its own four stroke cycle, but all cylinders do not pass through the sequence of events simultaneously. While one cylinder is operating on the power stroke, others are passing through the compression, exhaust, or intake strokes, timed accurately to occur in the correct sequence and at the right instant. This arrangement provides a virtual steady flow of power. Regardless of the number of cylinders on the engine, two complete revolutions of the crankshaft are required for all pistons to accomplish their four stroke cycle.

Each event in this five event sequence - intake, compression, ignition, power, and exhaust - is essential. However, it is only when ignition is added to the other four events and takes place in the proper sequence that the engine will operate. If the ignition switch is turned off, the mixture will not be ignited, there will be no power stroke, and the engine will stop. Also, if the gasoline supply is shut off, there is no gasoline in the cylinder to ignite and, therefore, no power event occurs and the engine stops. In order to start the engine initially, the crankshaft must be rotated by an outside source of power until the ignition and power event take place. This rotation is generally accomplished by an electric motor - a starter - geared to the crankshaft.