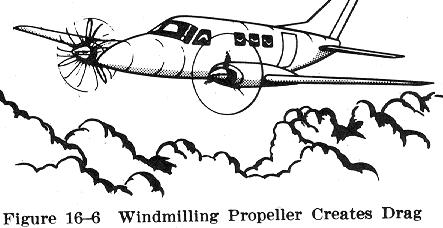

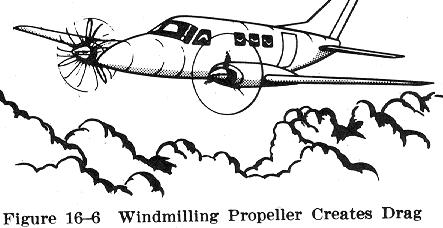

When an engine fails in flight the movement of the airplane through the air tends to keep the propeller rotating, much like a windmill. Since the failed engine is no longer delivering power to the propeller to produce thrust but instead, may be absorbing energy to overcome friction and compression of the engine, the drag of the windmilling propeller is significant and causes the airplane to yaw toward the failed engine (Fig. 16-6). Most multiengine airplanes are equipped with "full feathering propellers" to minimize that yawing tendency.

The blades of a feathering propeller may be positioned

by the pilot to such a high angle that they are streamlined in the direction

of flight. In this feathered position, the blades act as powerful brakes

to assist engine friction and compression in stopping the windmilling rotation

of the propeller. This is of particular advantage in case of a damaged

engine, since further damage, caused by a windmilling propeller creates

the least possible drag on the airplane and reduces the yawing tendency.

As a result, multiengine airplanes are easier to control in flight when

the propeller of an inoperative engine is feathered.

Feathering of propellers for training and checkout purposes

should be performed only under such conditions and at such altitudes and

locations that a safe landing on an established airport could be accomplished

readily in the event of difficulty in unfeathering the propeller.