|

Chapter 3 — Components and Systems

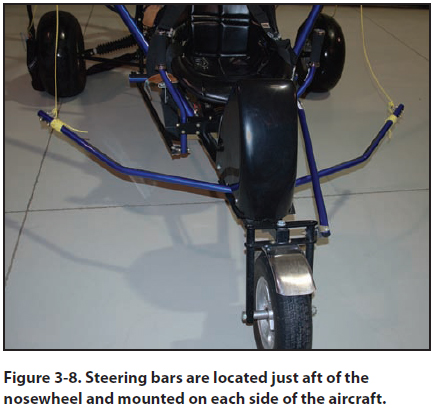

The Steering Bars

The steering bars are located just aft of the nosewheel

and mounted on each side of the aircraft; they move

forward and aft when the pilot applies foot pressure.

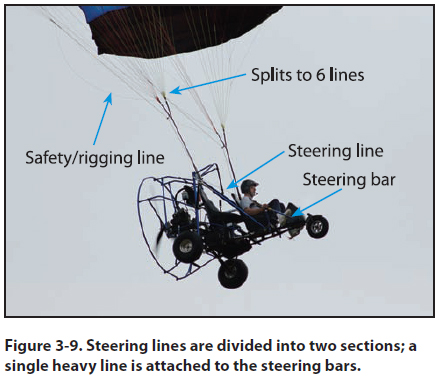

[Figure 3-8] The steering lines from the trailing

edge of the wing are attached to the outer ends of the

steering bars. (Some manufacturers have developed

a steering pedal system on their airframes, although

the steering lines function in the same manner.) The

main steering lines divide into various smaller lines,

which attach to multiple points on the trialing edge of

the wing. Pushing on either one of the steering bars

causes the steering lines to pull down the corresponding

surface of the trailing edge on the wing, creating

drag. This in turn slows that side of the wing and

banks the PPC into a turn.

Pushing both steering bars simultaneously causes

the steering lines to pull down equally on the trailing

edge, which causes two things to happen: it decreases

the powered parachute’s forward speed by increasing

the drag and it changes the shape of the wing, increasing angle of attack which increases lift. This

procedure, called “flaring” or “braking the wing” allows

the pilot to touch down at a slower rate of speed

and descent, thus creating a smoother landing, which

results in less wear and tear on the aircraft as a whole.

[Figure 3-9]

Wings and Components

The powered parachute wing is unique, as compared

to a fabric wing on an airplane, in that when it is not

inflated it loses its ability to produce lift. When a

powered parachute wing is inflated or pressurized, it

becomes semi-rigid and is capable of producing lift

and supporting a load. Rather than being bolted to the

fuselage like an airplane, the parachute wing is attached

to the cart by lines and cables which are known

as risers.

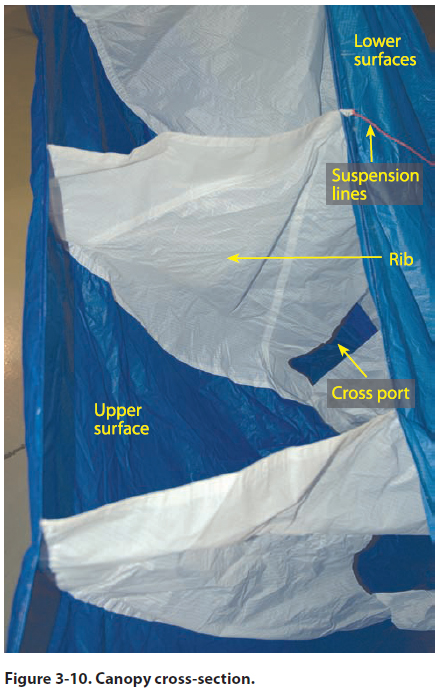

The wings are manufactured by attaching an upper

and lower section of skin to ribs. [Figure 3-10] The

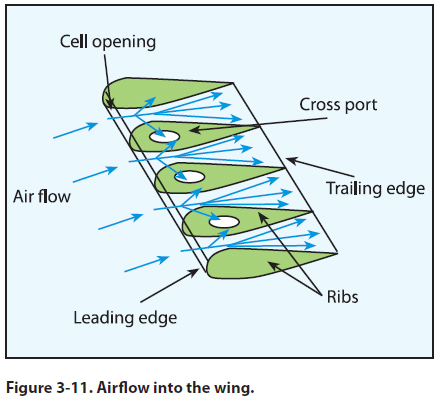

ribs of the wing determine the airfoil shape. [Figure

3-11] The shape of a powered parachute wing

will change slightly when faced with different gross

weights, air pressures, and environmental conditions

such as moisture, air temperature and wind.

Different wing manufacturers use different fabric

treatments to render the fabric airtight, so the air that

enters the wing cannot escape through the fabric surface.

The top surface of the wing is generally treated

to help protect it from ultraviolet light and the elements.

Keeping the powered parachute wing out of

direct sunlight will increase its useful life.

If the fabric degrades and air is allowed to escape

through pores of the cloth, the overall flight performance

of the wing is greatly reduced. If your powered parachute wing should become too porous, more

groundspeed may be needed to pressurize the wing,

takeoff distance may increase, more RPM may be

required to hold altitude, and fuel consumption may

increase.

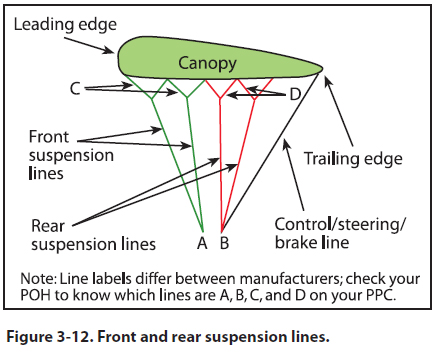

At first sight, the suspension lines on the powered

parachute wing might appear like an unorganized wad

of strings. On the contrary, each line has a distinct

purpose and each line has distinct properties. The suspension

lines are sometimes designated A through D

and differ between manufacturers; check your POH to

know the line labels for your PPC. [Figure 3-12] The

front suspension lines are located at the leading edge

and the steering lines connect to the trailing edge. The

suspension lines come together at a point where they

connect with the riser. (The risers are the connection

between the suspension lines and the cart.) Many

manufacturers color-code the wing suspension lines

to assist the pilot in their preflight inspection and layout

of the wing prior to inflation. [Figure 3-12]

Suspension lines must be constructed of very strong

materials, yet remain very small in profile to reduce

parasite drag. The most commonly used materials are

polyaramid and polyethelene, which are both carbon

based.

Kevlar® is a common polyaramid used for suspension

lines. Its properties render it extremely strong, as well

as resistant to stretching or shrinking, and it is not susceptible

to temperature changes. However, one critical

drawback of polyaramids is that they tend to kink

or knot when looped around. When polyaramids are

used to construct suspension lines, they are encased in

a skin of a terylene product, like Dacron® or a product

with similar properties. Polyethelene materials, such

as Spectra®, Dyneema® or Technora®, are very strong

as well as more flexible than polyaramids, which

makes them more durable under hard use. However,

polyethelene materials are more likely to stretch or

shrink, and they are more susceptible to temperature

changes. If your wing is equipped with polyethelene

suspension lines, it is imperative you do not store your equipment in a place that might experience extreme

temperatures. The POH or owner manual provided by

the chute manufacturer will specify limits for temperature

and storage.

Every line on the powered parachute wing is precisely

measured and fitted to a specific location. Therefore,

it is imperative to inspect the wing during preflight,

in addition to having the wing and its lines inspected

periodically by qualified technicians. The technician

will conduct strength tests as well as look for wear

and compromised attachment points; refer to your

wing manufacturer’s specifications for inspection

parameters. Under no circumstances should powered

parachute suspension lines be spliced or tied if severed!

Each line’s length and strength is specifically

calibrated. If you tie a knot in the line you will change

the specifically-engineered flight characteristics of the

wing, rendering it unairworthy.

|