|

This chapter covers the engines found on most powered

parachutes and includes the exhaust, ignition,

fuel, lubrication, cooling, propeller, gearbox, induction,

charging, and fuel systems. Reciprocating engine

operating theory is covered, for both two-stroke

and four-stroke engines.

The powered parachute engine and propeller, often

referred to as a powerplant, work in combination to

produce thrust. The powerplant propels the powered

parachute and charges the electrical system that supports

PPC operation.

The engine is one of the key components of a powered

parachute and should be maintained according to both

the engine and airframe manufacturer recommendations.

Preflight information, along with maintenance

schedules and procedures, can be found in the Pilot’s

Operating Handbook (POH) and/or maintenance references

from the manufacturers.

Engine inspections and maintenance must be performed

and documented in a logbook. You should

review this logbook before flying an unfamiliar powered

parachute.

Reciprocating Engines

Most powered parachutes are designed with reciprocating

engines. Two common means of classifying

reciprocating engines are:

1. By the number of piston strokes needed to

complete a cycle: two-stroke or four-stroke; and

2. By the method of cooling: liquid or air-cooled.

Refer to Chapter 5 of the Pilot’s Handbook of Aeronautical

Knowledge for a comprehensive review of

how reciprocating four-stroke engines operate.

Two-Stroke Engines

Two-stroke engines are commonly used in powered

parachutes. Two-stroke aviation engines evolved

from two-stroke snowmobile and watercraft engines, the difference being that an aircraft engine is optimized

for reliability with dual ignition often installed

for each cylinder. Two-stroke engines are popular because

they have fewer components than four-stroke

engines which makes them less expensive to manufacture,

and lighter, thus increasing their power-toweight

ratio.

Two-stroke engines require that oil be mixed into the

fuel to lubricate the engine, instead of being held in a

sump and having a separate recirculating system like

a four-stroke engine. Details on two-stroke oil mixing

are covered later under the “Lubrication” section.

One stroke as the piston moves up is intake and compression,

the second stroke as the piston moves down

is power and exhaust. The two-stroke engine performs

the same functions as a four-stroke engine in

half the strokes.

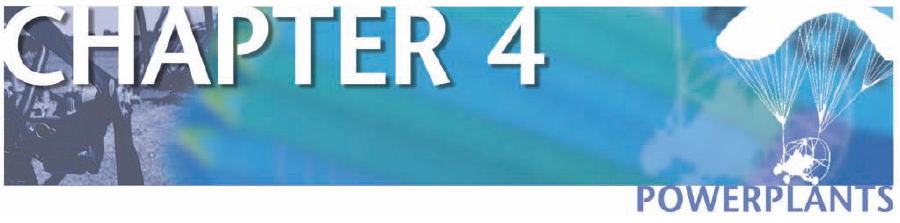

A wide range of valve systems are found on two

cycle engines, for the purpose of opening and closing

ports in the cylinder to let fuel in and exhaust out

at the proper time, similar to the intake and exhaust

valves on a four-stroke engine. One-way pressure

valves, called spring, reed, or poppet valves, open

when the pressure drops within the crankcase, pulling

the fuel from the carburetor into the crankcase.

[Figure 4-1]

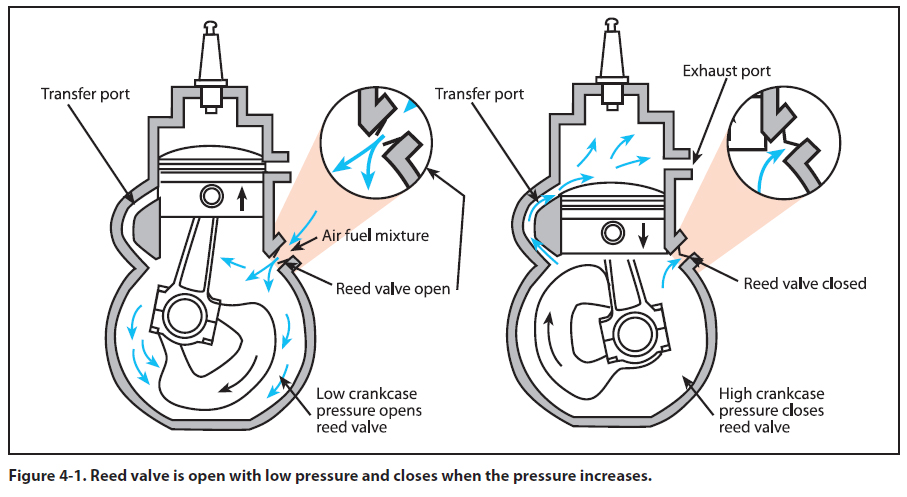

Mechanical rotary valves are driven off the engine,

rotate to provide an opening at the precise time, and

can be on the intake and exhaust ports. [Figure 4-2]

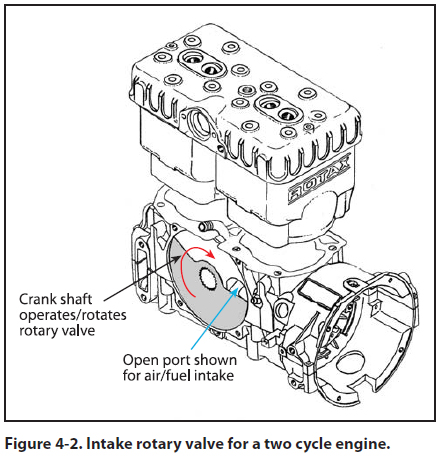

Piston porting does not use any valves. The fuel inlet

port is opened and closed by the piston position as

it moves up and down in the cylinder. This is called

a “piston ported inlet” and will be used in the Two-

Stroke Process description that follows. [Figure 4-3]

Two-Stroke Process

The two-stroke process begins with the fuel entering

the engine and concludes as it exits as exhaust.

[Figure 4-3]

Crankcase Vacuum Intake Stroke—Piston

Moving up: Figure 4-3 a to b

The upward stroke of the piston [Figure 4-3a] creates

a vacuum in the crankcase and pulls the fuel/

air/oil mixture into the crankcase through the intake

valve system from the carburetor. [Figure 4-3b] This

can be a pressure-actuated reed valve, a rotary valve,

or a third ported inlet system where the lower piston

skirt provides an opening for the fuel/air/oil mixture

to flow in when the piston is reaching its highest

point Top Dead Center (TDC). At this point, the

greatest portion of the fuel/air/oil mixture has filled

the crankcase.

Crankcase Compression Stroke—Piston

Moving down: Figure 4-3 b to c

During the downward stroke, the pressure valve is

forced closed by the increased crankcase pressure,

the mechanical rotary valve closes, or the piston

closes off the fuel/air oil mixture intake port. The

fuel mixture is then compressed in the crankcase

during the downward stroke of the piston.

Crankcase Transfer/Exhaust—Piston at lowest:

Figure 4-3 d

When the piston is near the bottom of its stroke, the

transfer port opening from the crankcase to the combustion

chamber is exposed, and the high pressure

fuel/air mixture in the crankcase transfers around the

piston into the main cylinder.

This fresh fuel/air/oil mixture pushes out the exhaust

(called scavenging) as the piston is at its lowest point and the exhaust port is open. Some of the fresh fuel/

air/oil mixture can escape out the exhaust port resulting

in the higher fuel use of the two stroke engine.

Cylinder start of Compression Stroke—Piston

initially Moving up: Figure 4-3 e

As the piston starts to move up, covering the transfer

port, the tuned exhaust bounces a pressure wave at

the precise time across the exhaust port (more on

this in the exhaust system discussion) to minimize the fuel/air/oil mixture from escaping out the exhaust

port.

Cylinder Compression Stroke—Piston Moving

Up: Figure 4-3 e to f

The piston then rises, and compresses the fuel mixture

in the combustion chamber. During this piston

compression process, the crankcase vacuum intake

process is happening simultaneously, as described

earlier. This is why four processes can happen in two

strokes.

Cylinder Power Stroke—Piston Moving Down:

Figure 4-3 f to g

At the top of the stroke, the spark plug ignites the

fuel mixture and drives the piston down as the power

stroke of the engine.

Cylinder Power Stroke—Piston Moving Down:

Figure 4-3 g to h

As the piston passes the exhaust port, the exhaust

starts to exit the combustion chamber. As the piston

continues down, the transfer port opens and the

swirling motion of the air/fuel/oil mixture pushes the

exhaust out the exhaust port.

Piston Reverses Direction From Down Stroke to

Up Stroke: Figure 4-3 h to a

As the piston reverses direction from the down

stroke to the up stroke the process is complete.

|