|

Chapter 4 — Powerplants

Four-Stroke Engines

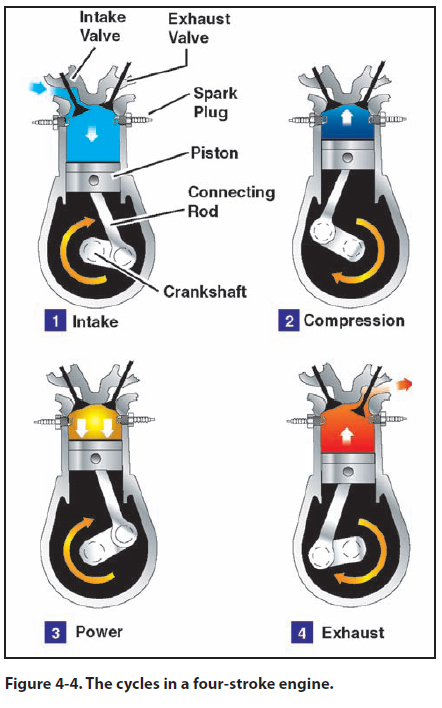

Four-stroke engines are very common in most aircraft

categories, and are becoming more common in

powered parachutes. [Figure 4-4] Four-stroke engines

have a number of advantages, including reliability,

fuel economy, longer engine life, and higher horsepower

ranges.

These advantages are countered by a higher acquisition

cost, lower power-to-weight ratios, and a higher

overall weight. The increased weight and cost are

the result of additional components, e.g., camshaft,

valves, complex head to house the valve train, etc.,

incorporated in a four-stoke engine.

These advantages are countered by a higher acquisition

cost, lower power-to-weight ratios, and a higher

overall weight. The increased weight and cost are

the result of additional components, e.g., camshaft,

valves, complex head to house the valve train, etc.,

incorporated in a four-stoke engine.

Engine exhaust systems vent the burned combustion

gases overboard, reduce engine noise, and (in the

case of two-stroke engines) help keep the fresh fuelair

mixture in the cylinders. An exhaust system has

exhaust piping attached to the cylinders, as well as

a muffler. The exhaust gases are pushed out of the

cylinder and through the exhaust pipe system to the

atmosphere.

Some exhaust systems have an exhaust gas temperature

probe. This probe transmits an electric signal to

an instrument in front of the pilot. This instrument

reads the signal and provides the exhaust gas temperature

(EGT) of the gases at the exhaust manifold. This

temperature varies with power and with the mixture

(ratio of fuel to air entering the cylinders), and is used

to make sure the fuel-air mixture is within specifications.

When there is a problem with carburetion, the

EGT gauge will normally be the first notification for

a pilot.

Two-Stroke Tuned Exhaust Systems

In two-stroke engines, the exhaust system increases

the fuel economy and power of the engine. The twostroke

exhaust system is an integral part of any twostroke

engine design; often controlling peak power

output, the torque curve, and even the RPM limit of

the engine.

The exhaust system must be tuned to produce a back

pressure wave to act as an exhaust valve. When hot

spent gases are vented out of the exhaust port, they are

moving fast enough to set up a high-pressure wave.

The momentum of that wave down the exhaust pipe

diffuser lowers the pressure behind it. That low pressure

is used to help suck out all of the residual, hot,

burnt gas from the power stroke and at the same time help pull a fresh fuel-air charge into the cylinder. This

is called scavenging and is an important function of a

tuned two-stroke exhaust system.

The design of the exhaust converging section causes

a returning pressure wave to push the fresh fuel-air

charge back into the exhaust port before the cylinder

closes off that port. That is called pulse-charging and

is another important function of the exhaust system.

Tuned exhaust systems are typically tuned to a particular

RPM range. The more a certain RPM range

is emphasized, the less effective the engine will operate

at other RPMs. Vehicles like motorcycles take

advantage of this with the use of transmissions. Motorcycle

exhaust pipe builders can optimize a certain

RPM range and then the driver shifts gears to stay in

that range. Aircraft, with no transmission, do not have

this ability.

On an aircraft, an exhaust pipe has to be designed to

operate over a broad range of RPMs from idle to full

speed. This is part of the reason that simply putting a

snowmobile engine on a powered parachute doesn’t

work well.

Overall, the two-stroke exhaust system for a PPC is

a specific design and must be matched to the engine

to operate properly and obtain the rated power. It also

reduces noise and directs the exhaust to an appropriate

location. Exhaust silencers can be added to reduce

noise but additional weight, cost, and slight power reduction

are the byproducts.

Four-Stroke Engine Exhaust Systems

Four-stroke engines are not as sensitive as two-stroke

engines because they have exhaust valves and therefore

do not need the precision pulse tuned exhaust system.

However, directing the exhaust out appropriately

and reducing the noise are important considerations.

Again, using the manufacturer’s recommended configurations

is required for Special Light Sport Aircraft

(S-LSA) and recommended for Experimental Light

Sport Aircraft (E-LSA).

Two-Stroke Engine Warming

Two-stroke engines must be warmed up because metals

expand at different rates as they heat up. If you

heat up steel and aluminum, you will find that the aluminum

parts expand faster than the steel parts. This

becomes a problem in two different areas of many

two-stroke engines. The first place is in the cylinders

of the engine.

The cylinders have steel cylinder walls that expand

slowly compared to aluminum pistons that expand

quickly. If an engine is revved too quickly during

takeoff before warming up, a lot of heat is generated

on top of the piston. That quickly expands the piston,

which can then seize in the cylinder. A piston seizure

will stop the engine abruptly.

The second area of concern is lower in the engine

around the engine crankshaft. This is an area where

things may get too loose with heat, rather than seizing

up. Additionally, the crankcase has steel bearings set

into the aluminum which need to expand together or

the bearings could slip.

Many two-stroke engines have steel bearings that normally

hug the walls of the aluminum engine case. The

crank spins within the donuts of those steel bearings.

If you heat up the engine two quickly, the aluminum

case will out-expand those steel bearings and the

crank will cause the bearings to start spinning along

with it. If those steel bearings start spinning, they can

ruin the soft aluminum walls of the case, which is

very expensive.

If heat is slowly added to an engine, all the parts will

expand more evenly. This is done through a proper

warm-up procedure. Many two-stroke engines are

best warmed up by running the engine at a set RPM

for a set amount of time. Follow the instructions in

your POH; however, a good rule of thumb is to initially

start the engine at idle RPM, get it operating

smoothly, and then warm the engine at 3,000 RPM

for 5 minutes.

Once the engine is warmed up and the powered parachute

is flying, it is still possible to cool down the

engine too much. This will happen when the engine is

idled back for an extended period of time. Even though

the engine is running, it is not generating as much heat

as the cooling system is efficiently dumping into the

atmosphere. An immediate power application with a

cooled engine can seize the engine just as if the engine

had not been warmed in the first place.

In water-cooled engines, on a long descent at idle, the

coolant cools until the thermostat closes and the engine

is not circulating the radiator fluid through the

engine. The engine temperature remains at this thermostat

closed temperature while the radiator coolant

continues to cool further. If full throttle is applied, the

thermostat can open allowing a blast of coolant into

the warm engine. The piston is expanding because of

the added heat and the cylinder is cooling with the

cold radiator water resulting in a piston seizure. To prevent this, slowly add power well before you get

close to the ground where you will need power. This

will give the system a chance to gradually open the

thermostat and warm up the radiator water.

Just as it takes a while for the engine crankcase and

bearings to warm up, it also takes those steel parts a

long time to cool down. If you land, refuel and want

to take off again quickly, there is no need to warm up

again for 5 minutes. The lower end of the engine will

stay warmed up after being shut down for short periods.

An engine restart is an example where it would

be appropriate to warm the engine up until the gauges

reach operating temperatures. The lower end of the

engine is warm and now you only need to be concerned

with preventing the pistons from seizing.

|