|

Chapter 4 — Powerplants

Centrifugal Clutch

Some gearboxes come with a built-in centrifugal

clutch, and others have allowances for installation. A

centrifugal clutch is very useful in a two-stroke engine

because it allows the engine to idle at a lower speed

without the load of the propeller. Otherwise, twostrokes

can generate a lot of vibration at low RPM

when loaded. As the engine speeds up, the centrifugal

clutch engages the rest of the gearbox and smoothly

starts the propeller spinning. When the engine is

brought back to idle, the clutch disengages and allows

the engine to again idle smoothly; the propeller stops

when on the ground and windmills when flying.

Propeller

The propeller provides the necessary thrust to push

the powered parachute through the air. The engine

power is used to rotate the propeller, which in turn

generates thrust very similar to the manner in which

a wing produces lift. The amount of thrust produced

depends on the airfoil shape, the propeller blade angle

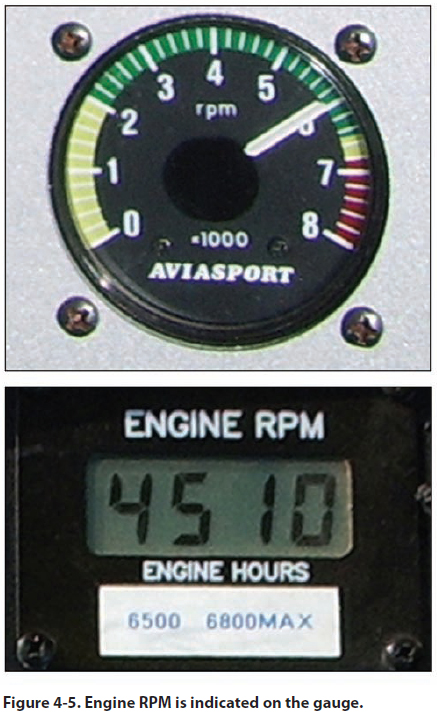

of attack, and the engine RPM. [Figure 4-5] Powered

parachutes are equipped with either a fixed-pitch or

ground adjustable pitch propeller.

Fixed-Pitch Propeller

The pitch of this propeller is set by the manufacturer

and cannot be changed. Refer to Chapter 5 of the

Pilot’s Handbook of Aeronautical Knowledge for basic

propeller principles.

Ground Adjustable-Pitch Propeller

Adjustable-pitch propellers for PPCs can only be adjusted

on the ground with hand tools. If an engine is

over-revving, more pitch can be added to the propeller.

If the engine is not developing the full recommended

RPM during flight, then some pitch can be taken out

of the blades. This should be done per the PPC’s POH

and by a qualified technician.

Induction Systems

The induction system brings air in from the atmosphere,

mixes it with fuel, and delivers the fuel-air mixture to the cylinder where combustion occurs.

Outside air enters the induction system through an air

filter on the engine. The air filter inhibits the entry of

dust and other foreign objects. Two types of induction

systems are used in powered parachute engines:

1. The carburetor system is most common; it mixes

the fuel and air in the carburetor before this

mixture enters the engine intake, and

2. The fuel injection system, which injects the fuel

into the air just before entry into each cylinder.

Carburetor Systems

PPCs use float-type carburetors. Reference the Pilot’s

Operating Handbook of Aeronautical Knowledge for

basics on float carburetor operation.

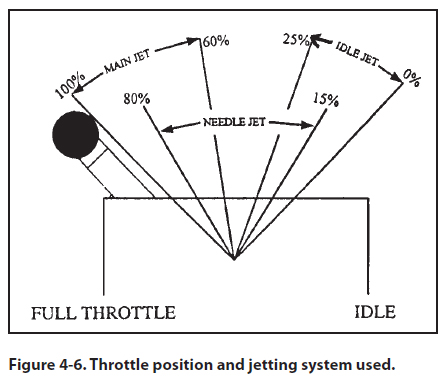

Modern two- and four-stroke carburetors operate with

one of three jetting systems, depending on engine

power. [Figure 4-6]

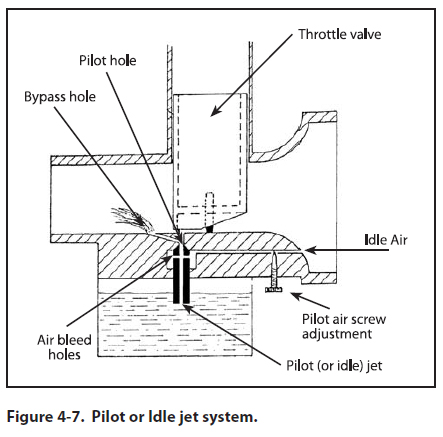

When the throttle is closed, for engine idling, the throttle

valve is closed and the fuel is supplied through the

idle (pilot) jet and idle (pilot) air passage. The fuel/air/oil mixture is supplied to the cylinders through the

bypass hole. [Figure 4-7]

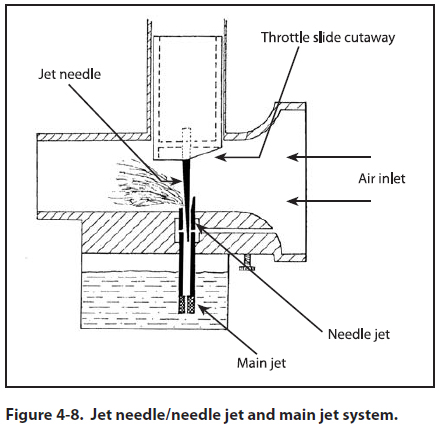

As the throttle is advanced and the throttle valve is

raised, the fuel is sucked up through the main jet but

is controlled by the opening and taper of the jet needle

and needle jet. This is effective throughout most

of the mid range operation. About half throttle, the

main jet size starts to influence the amount of fuel

mixed with the air and this effect continues until it

is the main influence at the highest throttle settings.

[Figure 4-8]

|