|

Chapter 4 — Powerplants

Four-Stroke Mixture Settings

Four-stroke engines typically have automatic mixture

control for higher altitudes or a mixture control that

can be operated by the pilot.

Carburetor Icing

One disadvantage of the carburetor system versus the

fuel injected system is its icing tendency. Carburetor

ice occurs due to the effect of fuel vaporization

and the decrease in air pressure in the venturi, which

causes a sharp temperature drop in the carburetor. If

water vapor in the air condenses when the carburetor

temperature is at or below freezing, ice may form

on internal surfaces of the carburetor, including the

throttle valve.

Ice generally forms in the vicinity of the venturi throat.

This restricts the flow of the fuel-air mixture and reduces

power. If enough ice builds up, the engine may

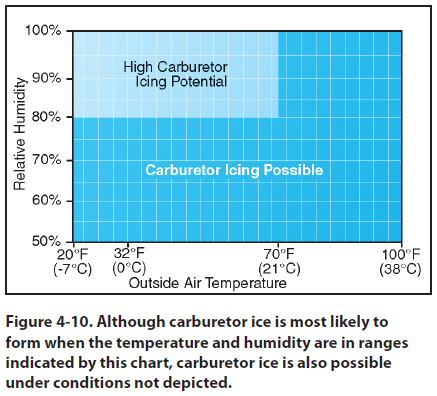

cease to operate. Carburetor ice is most likely to occur

when temperatures are below 70°F (21°C) and the

relative humidity is above 80 percent. However, due

to the sudden cooling that takes place in the carburetor,

icing can occur even with temperatures as high

as 100°F (38°C) and humidity as low as 50 percent.

This temperature drop can be as much as 60 to 70°F.

Therefore, at an outside air temperature of 100°F, a

temperature drop of 70°F results in an air temperature

in the carburetor of 30°F. [Figure 4-10]

The first indication of carburetor icing in a powered

parachute is a decrease in engine RPM, which may be

followed by engine roughness. Although carburetor

ice can occur during any phase of flight, it is particularly

dangerous when using reduced power during a

descent. Under certain conditions, carburetor ice could

build unnoticed until you try to add power. To combat

the effects of carburetor ice, some engines have a carb

heat option. Some of the newer four-stroke engines

have carburetor heat turned on all the time to combat

icing. Two-stroke engines are typically less susceptible

to icing but specific installations dictate how susceptible

the carburetor is to icing. Consult the aircraft

POH for the probability of carb ice for the specific

installation you have and for carb ice procedures.

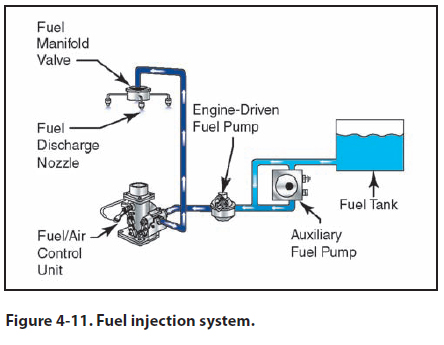

Fuel Injection Systems

In a fuel injection system, the fuel is injected either

directly into the cylinders, or just ahead of the intake

valve. A fuel injection system usually incorporates

these basic components: an engine-driven fuel pump,

a fuel-air control unit, fuel manifold (fuel distributor),

discharge nozzles, an auxiliary fuel pump, and fuel

pressure/flow indicators. [Figure 4-11]

The auxiliary fuel pump provides fuel under pressure

to the fuel-air control unit for engine starting and/or

emergency use. After starting, the engine-driven fuel

pump provides fuel under pressure from the fuel tank

to the fuel-air control unit. This control unit, which

essentially replaces the carburetor, meters the fuel and

sends it to the fuel manifold valve at a rate controlled

by the throttle. After reaching the fuel manifold valve,

the fuel is distributed to the individual fuel discharge

nozzles. The discharge nozzles, which are located in

each cylinder head, inject the fuel-air mixture directly

into each cylinder intake port.

Some of the advantages of fuel injection are:

• No carburetor icing.

• Better fuel flow.

• Faster throttle response.

• Precise control of mixture.

• Better fuel distribution.

• Easier cold weather starts.

Disadvantages include:

• Difficulty in starting a hot engine.

• Vapor locks during ground operations on hot

days.

• Problems associated with restarting an engine

that quits because of fuel starvation.

|