|

Chapter 5 — Preflight and Ground Operations

Wing Inspection

The powered parachute flight instructor will spend a

great deal of time explaining the systems of the wing,

the proper preflight, and the different methods of staging

the wing for inflation by means of different layout

techniques. The wing, and its performance, is critical

to flight and safety; once again a thorough and systematic

preflight procedure is essential.

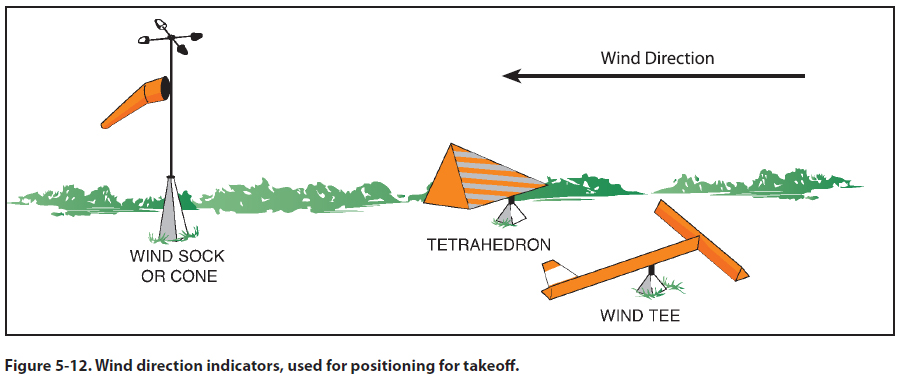

Check the wind direction and manually point the cart

directly into the wind. Many PPC pilots use a telescoping

rod with a windsock or long strip of narrow

rip-stop suspended from the top, displayed from their

powered parachute trailer or vehicle to determine wind

direction and wind speed. Some pilots prefer handheld

wind speed/direction devices. Most conventional

airports have some sort of wind indicator (windsock,

wind T, etc.) positioned in the segmented circle, as

well as electronic weather indicators that accurately

measure wind speed and direction at the field. Once

the powered parachute engine starts it will be nearly

impossible for the pilot to determine the direction of

the wind without the aid of a wind direction indicator.

[Figure 5-12]

Remove the wing bag from its stored position on the

airframe, either on the rear or pilot’s seat, or hanging

from the airframe itself. It is critical that the bag not

be twisted, rotated or turned when removing it from

its storage location, as doing so will twist and entangle

the suspension lines. Another determining factor

in keeping the suspension lines free from is how you

packed the wing away the last time it was flown; the

proper procedure for re-bagging the PPC wing will be

covered at the end of this chapter.

It is critical for the powered parachute pilot to be able

to recognize when the suspension lines are twisted

and to know how to untwist them. Most wing bags

are clearly marked with an emblem or other marking

to identify one side of the bag from the other. Keeping

the marked side of the wing bag always facing

in the same direction (either facing the cart or facing

away from the cart) is a helpful reference to determine

if you have twisted the suspension lines while

moving the wing into place, either on or behind the

cart. The key is to be consistent and methodical in

whatever procedure you use. Your flight instructor

will offer input on a practical procedure. The height

and physical strength of the pilot will also be a factor

in determining the best position on the cart to store

the wing bag.

Place the wing bag on the ground directly behind the

airframe as far back as the riser and support lines will

allow, keeping the wing bag in the same configuration

that it was removed from the cart. You will have to pull

both line sleeves that hold the suspension lines out of the wing bag, and one line sleeve up and around the

cart to follow the bag; those lines should run straight

from the attach points on the cart to the wing bag after

the bag is in position behind the cart. Tilt the wing bag

toward the cart to spill the folded wing out of the bag

and onto the ground. [Figure 5-13]

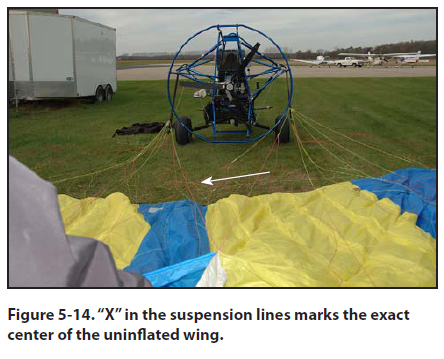

With the wing folded behind the cart, you are ready

to spread it out and in doing so begin to visually inspect

the uninflated wing. Unfold the right side of the

wing toward the right and repeat on the left side. As

you unfold the wing, it should remain centered directly

behind the cart. After the wing is completely

unfolded, stand directly behind the cart and hold the

leading edge of the wing up in front of you as you

face the backside of the cart. You will see an “x” in the

lines; this “x” should be positioned directly behind

the centerline of the prop on the cart. [Figure 5-14] If

it is not, physically pick up the center and drag it into

the center position. Then go to the end of the side that

will be bunched up and pull out the slack.

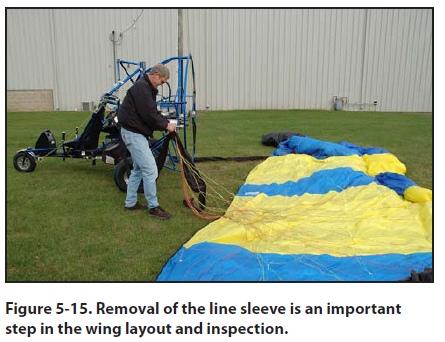

Remove the protective sleeves that cover the suspension

lines and their components. The protective

sleeves are referred to as line sleeves and there is a

line sleeve on each set of lines (or two—

the right and

the left). [Figure 5-15]

While laying out the wing, check for tears in the fabric,

torn or loose stitching, abrasions, and deterioration

of the fabric from ultraviolet rays. The sun is one

of the powered parachute wing’s worst enemies, next

to the prop! Certain colors deteriorate faster than others,

like red and orange, when exposed to ultraviolet

rays from the sun. When the wing is not being used,

you should always return it to its wing bag. Take this

opportunity to check the wing cells for debris, such as

stones, sticks, and bugs; lifting the wing by the trailing

edge and gently shaking it will allow most captured

debris to fall out of the ram-air openings on the

leading edge of the wing.

With the wing centered behind the cart, it is time to

start checking the suspension lines. At first glance

it may look difficult to sort out all of the lines from

the cart to the wing. Most of the time, the lines will

straighten out with just a light flick of the wrist. Make

sure you have no twists or line-overs and your lines

are straight. As long as the wing has not been physically

removed, or disconnected from the cart, there

should not be any permanent knots in the lines. In

the event that you detect pressure knots during the

line inspection they are easily removed with minimal

manipulation.

Small twigs, stems from weeds, and other debris can

get caught in the lines to form pressure knots. Pressure

knots are a concern because they are only “knots”

when there is tension on the lines. That means they are

only a problem when your wing is inflated. As soon

as you land, the foreign object often shakes free and

there is no knot. However, while you are flying, that pressure knot can cause the powered parachute to go

into a steep turn. Make sure there is nothing around to

catch into your line sets. The more organized the suspension

lines are laid out during this preflight check,

the more likely that the wing will kite evenly and

without mishap. It may take a great deal of space to

get all the cells open during the inflation of the wing.

Aborting the takeoff to re-kite the wing is always an

option, but it is not desirable. Preflight the wing correctly

the first time.

If you put your wing away correctly and took it out

as described, it should not have any twists in it. However,

you still need to check. Start where the risers attach

to the cart. Make sure they are not twisted around

anything and trace each one back to the point where

the wing risers are attached to the cart.

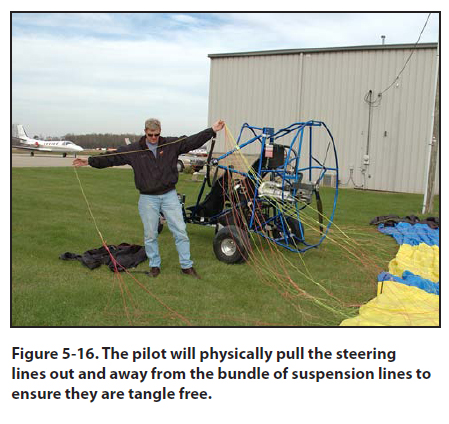

Check the steering lines on both sides of the cart;

make sure the anchor point knots are secure and the

lines flow freely through all guides and pulleys. Make

sure the links on both sides of the aircraft are secure;

it is recommended that the links are finger tight plus

one-quarter turn. Continue by checking that the riser

cables are not twisted or damaged and they are free

from tangles. At this time pull slack from the steering

lines so the steering bars are fully retracted. Physically

separating the steering lines from the suspension

lines, pulling them out and away to the outer edge of

the wingtips, enables you to visually see the steering

lines are free from being tangled with the rest of the

lines. [Figure 5-16]

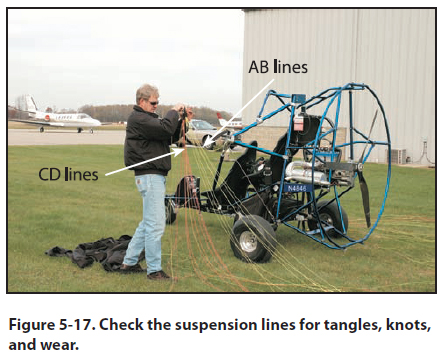

Continue to check the suspension lines for tangles,

knots and wear and the attachment points for security

and lack of fraying. [Figure 5-17] The A lines should

be visually and physically separated from the B lines

at the point where the lines are connected to the risers.

Most newer wing lines are color-coded to make

this process visually easier; the older wing styles will

still be separated and configured the same way as the

newer wings, however all the lines will be the same

color. The A lines will travel toward the leading edge

of the wing and subdivide into the C lines. The B lines

will travel toward the trailing edge of the wing and

subdivide into the D lines. Make sure that the lines

are all separated and not tangled. The A/C lines will

be on top of the B/D lines when the lines are returned

to the ground after the preflight of each section. Make

sure there is no debris around to catch in the line sets

during wing inflation; when the length of the line is

altered it changes how the line holds the wing. The

length of the lines are clearly defined by the manufacturers

and should not be changed. The more organized the suspension lines are laid out during this preflight

check, the more likely that the wing will kite evenly

and without mishap; a lot of runway can be used up

trying to get all the cells open during inflation of the

wing. Aborting the takeoff to re-kite the wing is always

an option, but it is not desirable. Preflight the

wing correctly the first time; taking your time will pay

off in the end.

|