|

Chapter 5 — Preflight and Ground Operations

Visual Inspection

The accomplishment of a safe flight begins with a

careful visual inspection, regardless of the category/

class of aircraft you will be flying. The purpose of the

routine preflight inspection is twofold: to determine

the powered parachute is legally airworthy, and that it

is in condition for safe flight. You determine whether

the PPC is in a condition for safe flight by a thorough

and systematic preflight inspection of the aircraft

and its components. The preflight inspection should

be performed in accordance with a printed checklist

provided by the powered parachute manufacturer for

the specific make and model of aircraft. However, the

following general areas are applicable to all powered

parachutes.

The preflight inspection should begin as soon as

you approach the aircraft. Since the powered parachute

can be transported by trailer, the unloading of

the aircraft allows you extra opportunity to look the

cart over from front to back and top to bottom. First

and foremost, you need to look for any damage that

may have occurred during transit. Make note of the

general appearance of the aircraft, looking for obvious

discrepancies such as tires with low air pressure,

structural distortion, wear points, cart damage, and

dripping fuel or oil leaks. All tie-downs, control locks,

and chocks should be removed during the unloading

process.

It is absolutely necessary you are thoroughly familiar

with the locations and functions of the aircraft systems,

switches, and controls. Use the preflight inspection

as an orientation when operating a make/model

for the first time.

The actual “walk around” is a routine preflight inspection

and has been used for years from the smallest

general aviation airplane to the largest commercial

jet. The walk around is thorough and systematic, and

should be done the same way each and every time an

aircraft will be flown. In addition to “seeing” what

you’re looking at, it requires you take the appropriate

action whenever a discrepancy is discovered. A

powered parachute walk around will cover five main

tasks:

1. Cart inspection

2. Powerplant inspection

3. Equipment check

4. Engine warm-up and check

5. Wing and suspension line inspection

Each PPC should have a specific routine preflight inspection

checklist, but the following can be used as a

guideline for most PPCs.

Cart Inspection

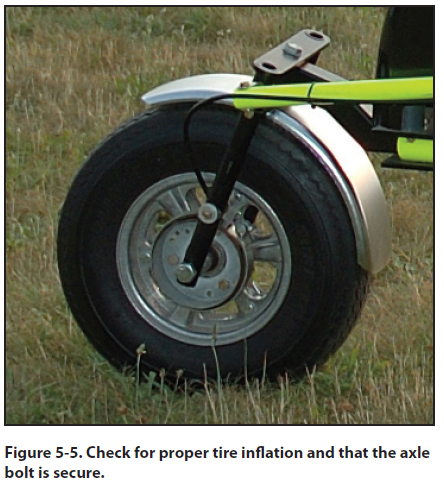

Check the front nosewheel for proper play, tire inflation,

and secure axle bolt. Test the ground steering bar

connection points and ensure there is smooth steering

range of motion from the steering bar. Check and secure

the connections between the front fork and the

front axle and the front fork and the gooseneck. [Figure

5-5]

When brakes are installed, it is common for them to

be on the front nosewheel. Typically, they are drum

or disk style operated by a cable; it is important to

inspect the cable lock, assuring it is tight. The brakes

may be hydraulic disk brakes that also incorporate a

cable; in this case, inspect both components. Check

brakes and brake systems for rust and corrosion, loose

nuts/bolts, alignment, brake pad wear/cracks, signs of

hydraulic fluid leakage, and hydraulic line security/

abrasion.

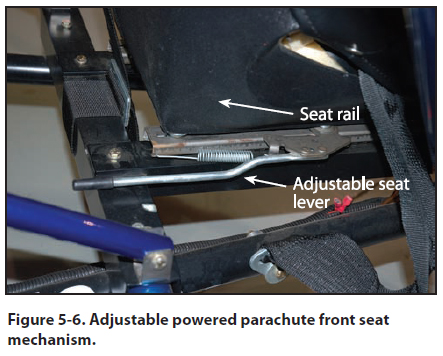

Inside the cart where the pilot sits, check the seats,

seat rails, and seat belt attachment points for wear,

cracks, and serviceability. A few manufacturers offer

powered parachutes with adjustable front seats. The

lever moves the pin in and out of the seat rail holes

and the seat then moves forward and back along the

rail. The seat rail holes should be checked for wear;

they should be round and not oval so there is no play in the fixed position of the pilot seat. Inspect where

the seat lock pins fit; check the pin and seat rail grips

for wear and serviceability. [Figure 5-6]

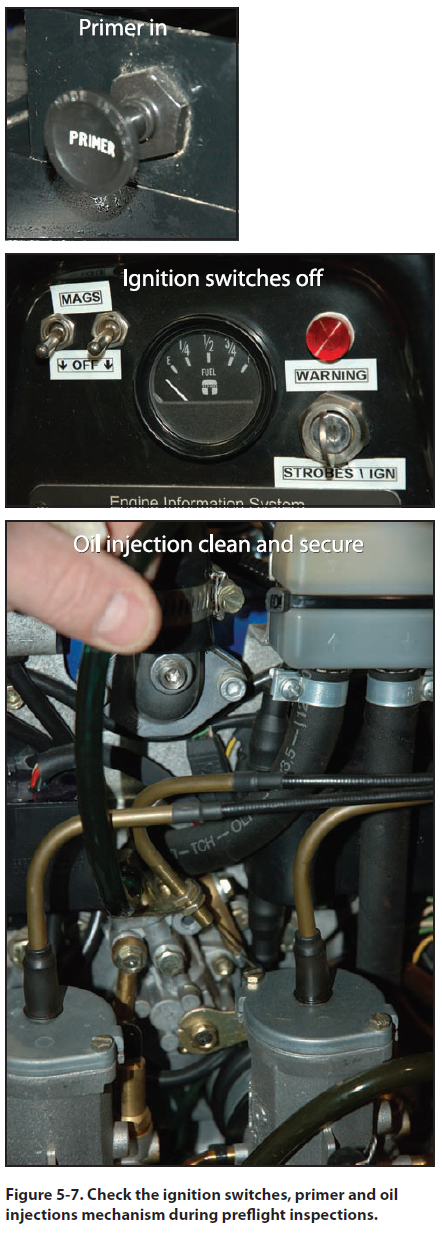

The battery and ignition switches need to be in the

OFF position at the beginning of the preflight inspection.

They will be turned on and then off again

to check the different components operated by the

power source during the preflight. While checking the

ignition switches, check that the strobe is operational

if one is installed. Exercise the primer or primer bulb,

if the PPC is so equipped; you should feel resistance

when exercised. Faulty primers can interfere with

proper engine operation.

Manipulate the engine throttle control by slowly

moving through its full range of motion to check for

binding or stiffness. On two-stroke engines with oil

injection, it is important to check that the oil injection

mechanism is moving freely. [Figure 5-7]

Set the altimeter to the field elevation or set in the

barometric pressure, if equipped. Turn on the ignition

or engine instrument system master and make note

of the fuel quantity gauge indications, if applicable,

for comparison with an actual visual inspection of the

fuel tank(s) during the exterior inspection.

Inspect for any signs of deterioration, distortion, and

loose or missing bolts or locknuts. Gently shake the

cart to determine if objects and airframe parts are

loose and need to be tightened. Treat all aircraft and

their components with respect and care while conducting

a preflight. As with all aircraft, the PPC does

not need to be “over-handled” to perform an adequate

preflight inspection. Check that all cables are free of

kinks, frays, abrasions or broken strands; check each

end of each flying cable for bolt security and check

that the thimbles are not twisted or elongated.

Check the steering bars for freedom of movement,

for proper steering line attachments, and confirm the

steering bars are securely attached.

Inspect the rear wheel and axle assembly. Check the

tires for proper inflation, as well as cuts, bruises, wear,

bulges, imbedded foreign objects, and deterioration.

As a general rule, tires with cord showing, and those

with cracked sidewalls are unairworthy. Check the

axle and axle hardware, and inspect that the wheels

rotate properly.

|