|

Chapter 5 — Preflight and Ground Operations

Fuel and Oil

Pay particular attention to the fuel quantity, type,

grade, and quality. Many fuel tanks are sensitive to attitude

when attempting to fuel for maximum capacity.

The powered parachute attitude can also be affected

laterally by a ramp that slopes. Always confirm the

fuel quantity indicated on the fuel gauge(s) by visually

inspecting the level of the fuel tank(s).

The engine manufacturer recommends the type of fuel

that any given powered parachute engine should burn;

this recommendation should be strictly conformed to.

Although most PPC engine manufacturers recommend

premium grade auto fuel, it is usually acceptable

to burn 100LL AVGAS on a limited basis. Most

airports will not have auto fuel available on the field.

Ensure the fuel caps have been securely replaced

following each fueling and the vents are free and

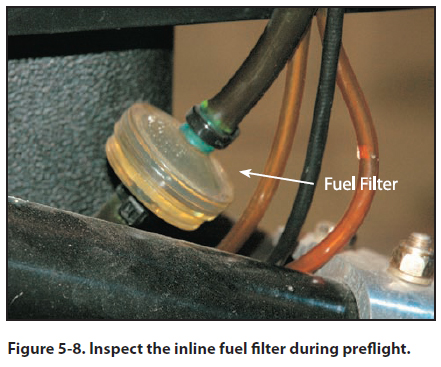

open. Most powered parachutes have an inline fuel

filter located somewhere between the tank and the

carburetors; check the fuel filter for contaminates.

[Figure 5-8]

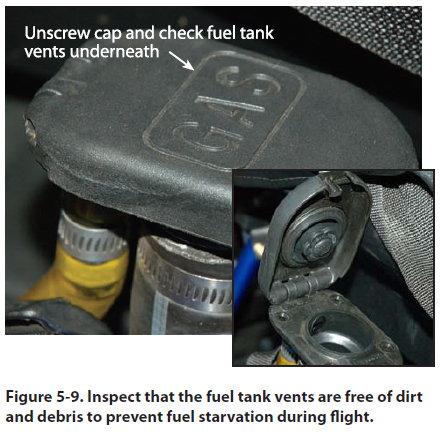

The fuel tank vent is an important part of all preflight

inspections. [Figure 5-9] Be alert for any signs of vent tubing damage, as well as vent blockage. A functional

check of the fuel vent system can be done simply by

opening the fuel cap. If there is a rush of air when

the fuel tank cap is opened, there could be a serious

problem with the vent system.

Check the oil reservoir to ensure the proper oil is

used. Check the oil level during each preflight and

after each refueling. [Figure 5-10] If the consumption

of oil steadily increases or suddenly changes, qualified

maintenance personnel should investigate. After

checking or adding oil to the PPC, ensure that the oil

cap has been securely replaced. The oil reservoir on a

two-stroke must be checked for adequate venting; if

this becomes plugged, it could cause starvation of the

oil to the engine.

Two cycle engines without oil injection premix the

oil with the fuel. Assure the mixture ratio is correct.

Proper mixing techniques is covered in the fuel section.

Powerplant Inspection

Inspect the propeller for any signs of propeller blade

chafing, and defects such as cracking. Check the propeller

for large nicks in the leading edge, cracks, pitting,

corrosion, and security. All propeller tape should

be securely attached to the propeller surface, paying

special attention to the convex side of the propeller

for any delaminating; propeller tape is used primarily

for protection on the leading edge of the propeller as

well as a supplemental balancing device. Check the

propeller hub for security, bolt threads showing and

general condition.

Powered parachute engines are set up in a pusher configuration,

so it is essential to check the engine area

for loose items to ensure nothing is blown through the

propeller, possibly injuring the aircraft, observers, or

property. Carburetor(s) must be checked to make sure

they are secure; check the air filter for condition and

secure fit. Check the rubber manifolds for cracks and

check spark plugs to make sure all of the spark plug

caps are secure. On some two-stroke engines, there

is a reservoir that contains the lubricant for the rotary

valve; check this level on every preflight. Check

gear reduction boxes for leaking seals and make sure

there is not play within the gears. Look for signs of

fuel dye which may indicate a fuel leak and deterioration

of fuel lines. Check for oil leaks, deterioration of

oil lines, and make certain that the oil cap, filter, oil

cooler and drain plug are secure.

Check the exhaust system for white stains caused

by exhaust leaks at the cylinder head or cracks in

the stacks. Check exhaust components for freedom

of movement; they must be secure with all exhaust

springs in place.

On liquid cooled engines, the radiator fluid level, as

well as the overflow reservoir, must be checked and

filled as necessary.

Check all visible wires and lines for security and condition.

|