Chapter 2

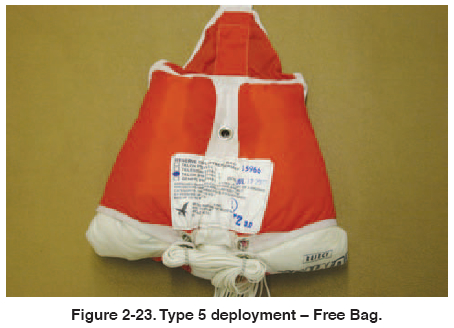

TYPE 5: FREE BAG

With a free bag, the canopy is stowed in the bag, and lines

are either stowed on or in the bag. They were originally

used on the Safety Flyer reserve. This is the dominant and

preferred method for virtually all modern square reserves.

[Figure 2-23]

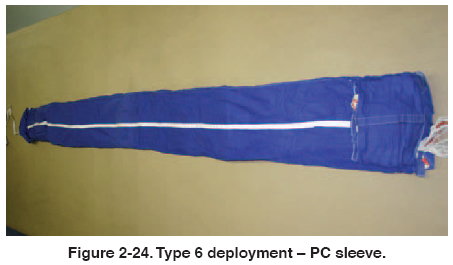

TYPE 6: SLEEVES

This includes a fabric tube which encloses the full length

of the folded canopy. Lines are stowed on the sleeve. They

were originally used on early sport canopies, particularly

the Para-Commander. [Figure 2-24] A modern version

known as a “slag” is used on some ram-air canopies.

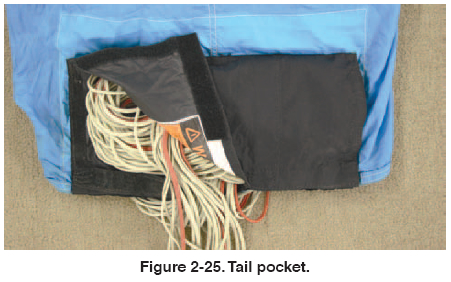

An additional deployment method is the “tail pocket.”

This is a fabric pocket sewn on the tail of a ram-air canopy

in which the lines are stowed. [Figure 2-25]

SECURING THE DEPLOYMENT DEVICE

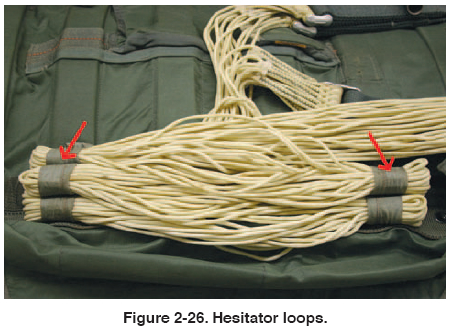

With all deployment methods, it is necessary to properly

fold or stow the canopy and secure the deployment device

with the lines. The early parachutes utilized hesitator

loops to secure the lines. [Figure 2-26] This method is

still used today in many military systems.

In modern designs that utilize types 1 through 4 and 6, the

preferred method of locking the deployment device is

rubber bands. The specification for standard rubber bands

is MIL-R-1832. Type 1 are natural rubber and are 1/2" x

2". These were designed for use with the thicker Type III

nylon lines such as on the 28' C-9 canopy. Many of the

newer lightweight, round canopies use smaller diameter

and fewer lines. Consequently, the standard rubber bands

do not work well. Some manufacturers supply smaller

diameter rubber bands to be used with their canopies. It is

extremely important to utilize the correct size rubber

bands.

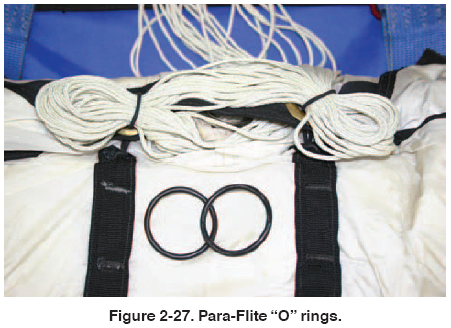

With the introduction of the free bag system in 1977,

Para-Flite, Inc., used a BUNA-N “O” ring to secure the

locking stows. [Figure 2-27] During testing of the free

bag system, they found inconsistent holding and breaking

strengths of rubber bands. They wanted the locking stows

to release at a consistent force to prevent bag lock. The

“O” rings provided this. A couple of years later, the “O”

rings were upgraded to a thicker diameter model. In 1983,

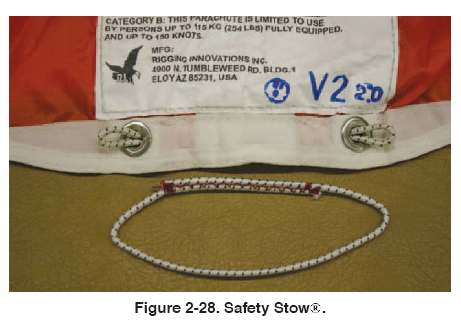

Para-Flite, Inc. replaced the “O” rings with the Safety

Stow®. The Safety Stow® is a continuous loop of elastic

shock cord that runs through a webbing channel and

through two grommets to secure the first two locking

stows. [Figure 2-28] In the event of any restriction on the

locking stow, as the loop stretches, it allows first one side

to release and then the opposite side. This design is a considerable

improvement over separate rubber bands or “O”

rings and is used on most free bags today.

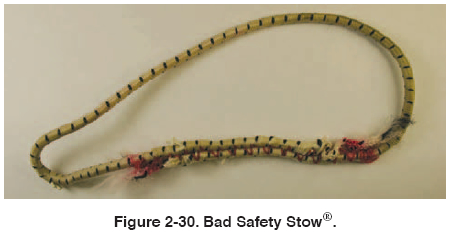

It is important to maintain the rubber bands or Safety

Stow®. Rubber bands are susceptible to heat degradation

and dry out. If they break prematurely during use, the

parachute may malfunction. Natural rubber bands also

react to natural brass grommets and may become gummy

and sticky, causing the lines to stick to the diaper or bag.

[Figure 2-29] The BUNA-N “O” rings should be replaced

with the Safety Stow®. The Safety Stow® should be

inspected for broken stitching or internal rubber strands.

[Figure 2-30]

|