Chapter 2

BRIDLES

The bridle is a cord or webbing strap, which is used to

connect the pilot chute to the canopy or deployment

device. Main and reserve bridles, while sharing the same

function, operate differently.

Early bridles were simply a length of suspension line tied

off to the two components. It was soon learned that the

length of the bridle affected the function of the pilot chute

and the opening characteristics of the canopy. If the bridle

is too short, the pilot chute cannot launch properly. If

too long, the snatch force is increased. On most round

emergency and reserve parachute assemblies, the length

and type of the bridle is fixed for optimum performance.

The rigger cannot change the configuration of the bridle

without approval of the manufacturer.

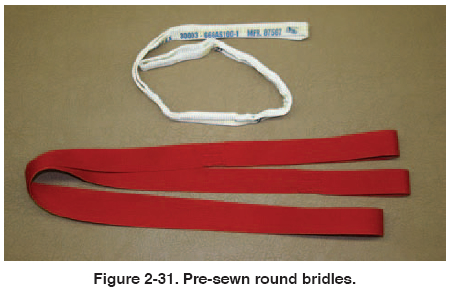

There are two basic types of round canopy bridles. The

first is a tubular nylon bridle that is tied on. The second

is a pre-sewn bridle with loops at each end. The loop of

one end is passed thru the attach point on the pilot chute

and then back thru itself forming a lark’s head knot. The

other loop of the bridle is then similarly attached to the

canopy apex. [Figure 2-31] With this type, it is essential

for the loop to remain loose to ensure the bridle is free

floating and self-centering around the apex lines. Hand

tack the loop to ensure this. [Figure 2-32]

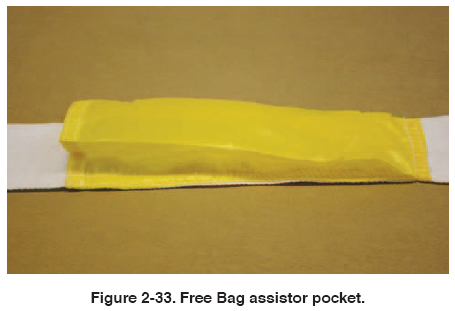

Square reserve bridles are generally built into the free

bag. The bridle material is usually 2" wide or more for

high drag. The original concept of the free bag is to allow

the square reserve to deploy if the reserve pilot chute is

captured resulting in a horseshoe-type malfunction. The high-drag bridle would then pull the reserve bag off the

parachutist’s back and allow the canopy to deploy free

from the bag. In the late 1980s, assistor pockets were

added to the bridles for additional drag as square reserves

became bigger and heavier. [Figure 2-33]

Early main bridles were simply longer versions of the

reserve bridles. This was necessary to compensate for the

“burble” created in free fall by the parachutist. In the mid

1970s and with the advent of the hand deploy pilot chute,

the length of the bridle was critical in order to allow

proper extraction of the locking pin that secured the pack

closed.

In recent years and with the almost total use of ram-air

parachutes, the need for collapsible main pilot chutes has

become widespread. As the main canopies have become

smaller and faster, the drag of the inflated main pilot

chute after opening can have an adverse effect on canopy

performance. This problem has been solved through the

use of a collapsible pilot chute/bridle system. There are

two primary designs used to accomplish this.

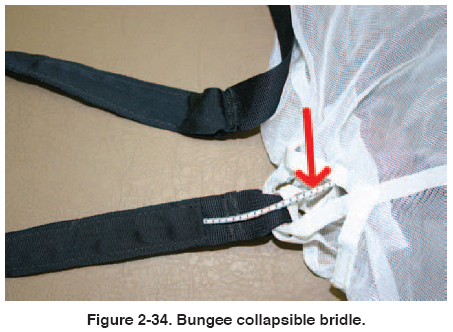

The first is the “bungee” collapsible configuration. This

consists of a length of elastic shock cord inside a tape

sheath on the bridle near the pilot chute end. [Figure 2-

34] When relaxed, it holds the apex of the pilot chute collapsed.

When the pilot chute is deployed into the

airstream, the airflow inflates the pilot chute which deploys the canopy. After opening, the elastic pulls the

apex down again and collapses the pilot chute, reducing

the drag. While this system works, its main drawback is

that certain airspeeds are needed to inflate the pilot chute.

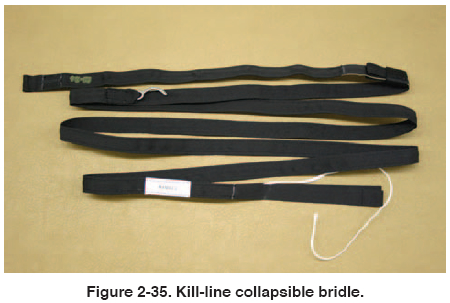

The second type is the “kill-line collapsible” configuration.

This consists of a bridle with a full length channel

through which passes a line of Kevlar® or Spectra®.

[Figure 2-35] The bridle is “cocked” and the lower end of

the bridle is collapsed during packing. This allows the

pilot chute to inflate immediately. During the deployment

sequence, as the canopy inflates, the lower end is

stretched to length and the centerline pulls the apex of

the pilot chute down and collapses it. This configuration

has become almost universal in use for skydiving today.

The only drawback is if the user forgets to cock the bridle

during packing. This will result in a collapsed pilot chute

and a pilot chute in tow. In the early days of use of the

kill-line bridle, this was a problem but has become less

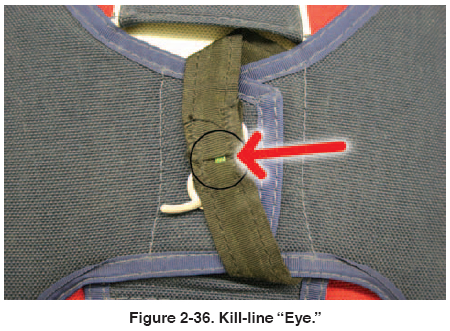

frequent today. A properly made bridle will have a colored

“eye” at the locking pin location to show if it is

cocked and the centerline is set correctly. [Figure 2-36]

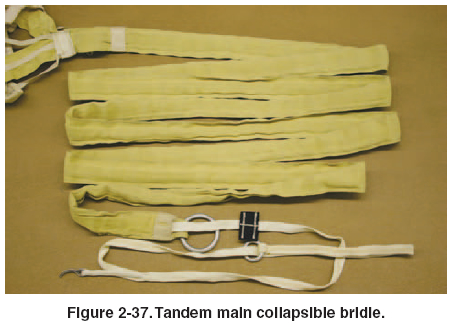

The kill-line configuration is used almost exclusively on

tandem systems due to the high speeds involved and the

size of the drogue pilot chutes. The bridles are usually made from 2" Kevlar® tape and have tubular nylon centerlines.

[Figure 2-37]

Another method of collapsing the pilot chute is to install

a No. 8 grommet in the deployment bag and allow the bag

to float on the bridle. After the canopy deploys, the bag

slides up the bridle, inverts, and covers the pilot chute.

This is commonly called the “poor man’s collapsible pilot

chute system.” The drawback to this design is the high

wear on the bridle and pilot chute mesh.

|