Chapter 2

RESERVE STATIC LINE SYSTEMS

A reserve static line (RSL) system is a backup device for

activating the reserve after a cutaway is performed. It

usually consists of a line, webbing, or cable, which connects

one or both main risers to the reserve handle, housing,

or cable. The most common design used today has a

ring through which the reserve ripcord cable is routed.

The riser end attaches to a ring on the riser(s) with a snap

shackle for quick release capability. When the risers are

jettisoned, the lanyard pulls the cable, releasing the ripcord

pin(s), and activates the reserve. This results in a

minimum loss of altitude during the cutaway procedure.

The use of an RSL has saved many lives over the years

due to low cutaways.

Though originally developed in 1964, the RSL concept

did not become popular until the advent of student piggyback

systems and ram-air canopies. Through the use of an

RSL system, the student parachutist need only pull the

canopy release handle in the event of a partial malfunction,

and the main canopy is cutaway and the reserve activates.

In 1990, the Parachute Industry Association urged

manufacturers to include RSLs as a standard feature on

all harness/container systems. Many did and this resulted

in an increase of RSL use for several years.

In recent years and with the widespread acceptance of

newer types of AADs, many parachutists feel that they no

longer need an RSL. In reality, both systems complement

each other. The AAD functions if the individual does not

activate the main parachute. However, it is altitude and

rate of descent (ROD) dependent. Below a certain altitude,

if the ROD is not met, the AAD will not function.

Consequently, if a cutaway is performed below the activation

altitude, it may take some time for the descending

parachutist to reach the ROD necessary to initiate activation,

thereby necessitating rapid manual activation of the

reserve. However, if an RSL is also installed, it would cause an immediate activation of the reserve as the main

parachute disconnects and moves away from the parachutist.

In the last few years, as canopy design has resulted in

smaller and more sensitive canopies, many parachutists

have elected not to use an RSL. The rationale is that in a

violently spinning malfunction, which some of these

highly loaded canopies are prone to do, it is preferable to

cutaway and regain stability prior to pulling the reserve.

This reduces the chance of an entanglement with the

deploying reserve. While this scenario has happened, it is

a rare occurrence. Statistics show that many lives have

been saved by using an RSL.

RSL DESIGNS

There are four primary design configurations of RSLs in use today.

1. A single side RSL where the lanyard is attached

to only one main riser, usually the left

side. [Figure 2-47] Only the one side is required

to release to activate the system. This is the

most common design in use today due to

its simplicity.

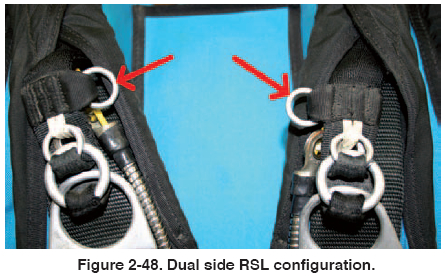

2. A dual side RSL where both main risers are connected

with a cross connector which is in turn

connected to the RSL lanyard. [Figure 2-48]

Both risers need to be released for the system to

function.

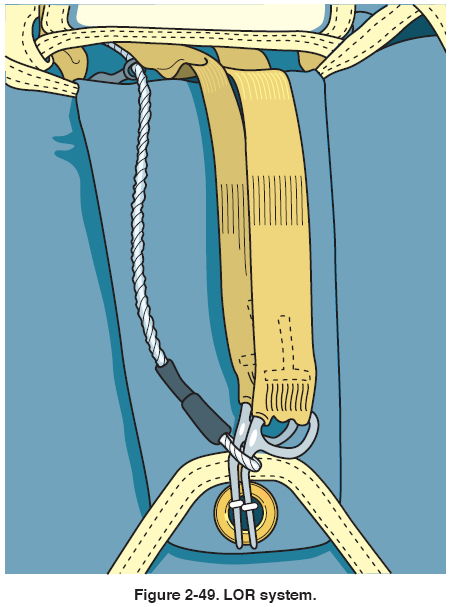

3. The LOR system developed by the French. This

incorporates two lanyards, one from each riser,

that are attached to individual curved pins that

secure the reserve container with a dual locking

loop. [Figure 2-49] Both risers must be released

for the system to function.

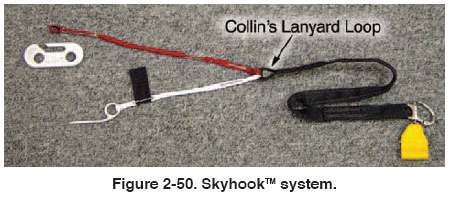

4. The Collins Lanyard/Skyhook™ system. This

design utilizes a special lanyard which is

attached to the bridle of the reserve free bag.

[Figure 2-50] Cutting away results in the free

bag being pulled directly out of the container by

the main risers and results in very little altitude

loss.

Since the early 1990s, most (if not all) manufacturers provide

an RSL installation on their equipment either as standard

or optional. If the rigger has a system without an

RSL and the owner wishes to have one installed, the rigger

should check with the manufacturer as to the availability

of a retrofit kit or return it to the manufacturer for

installation. Because the installation of an RSL is an alteration to the original design, the rigger needs approval

either from the manufacturer or the FAA.

Because of the nature of the RSL system, it is imperative

that the rigger thoroughly understands the individual concepts.

Unless he/she understands this, and has the

required manufacturer’s instructions, the rigger should

not attempt to assemble and pack a system with an RSL

installation. The following describes the basic design and

function of a single side RSL installation on a one-pin

reserve container.

|