Chapter 2

RIPCORD CABLE ROUTING

The routing of the ripcord cable from the handle to the

pin determines where the lanyard connects to the cable.

Most RSL attachments connect with the ripcord cable

either at the yoke area or just above the ripcord pin.

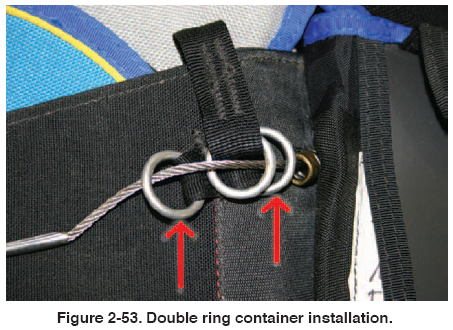

Generally, there is a double ring installation where the

cable end of the lanyard is located. [Figure 2-53] On this

particular installation, the connection is at the shoulder

yoke area.

RSL LANYARD AND CONTAINER MOUNT

These two components are interactive. That is, the design

of the container directly affects the design of the lanyard.

Once the two above locations are determined, then the

routing of the lanyard can be completed. It was originally

thought that the lanyard should have a long length to

allow acceleration during activation to pull the ripcord

cable. This has not proven to be true and most manufacturers

keep their lanyards as short as possible to prevent

snagging and easier stowing.

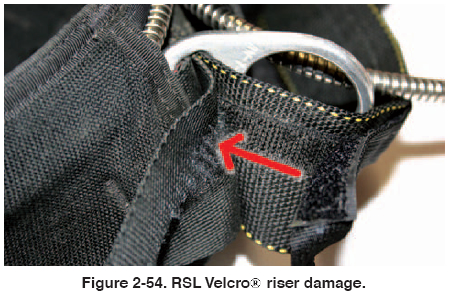

In the past, a Velcro® pathway was used for routing the

lanyard. This was either on the shoulder yoke or the

reserve riser. Experience has shown that the use of

Velcro® generally results in high wear and eventual damage

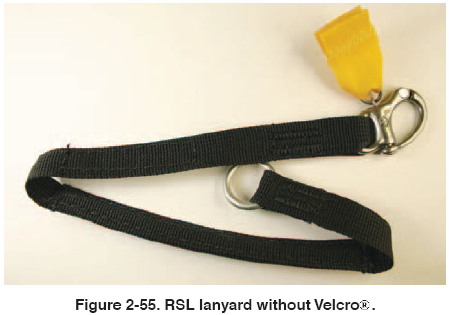

to the webbing. [Figure 2-54] On this design, the lanyard is stiffened with a short piece of coated cable and

stowed in two pockets located on the yoke area. [Figure

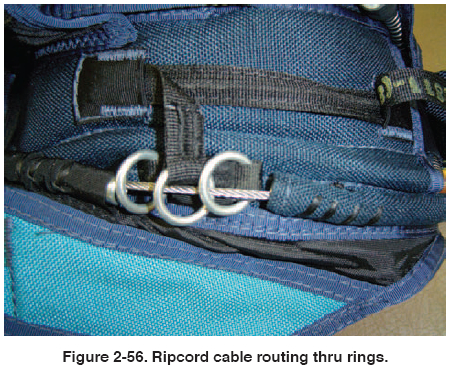

2-55] It is secure and has no wear points. The ripcord end

of the lanyard is routed to the dual guide ring attachment

location and the ripcord cable routed through the rings.

[Figure 2-56] The ripcord cable is then routed to the

reserve closing loop.

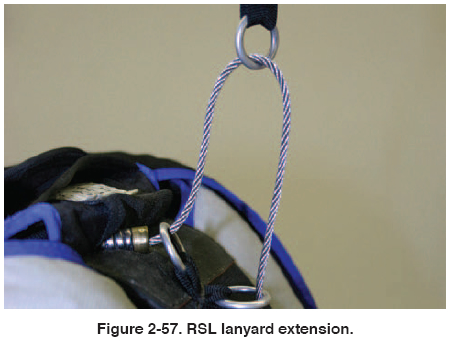

Figure 2-57 shows the RSL lanyard and ripcord cable at

the moment of riser extension and just as the cable is loaded. A point that the rigger should be aware of is the

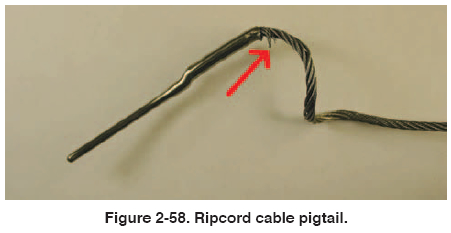

“pigtail” configuration of the reserve ripcord that results

from the use of the RSL. [Figure 2-58] Because of the

sliding of the ring along the ripcord cable, a curling effect

is imparted to the cable. This is a clear indication that the

RSL lanyard activated the reserve. The rigger should

carefully inspect the ripcord cable for any broken strands.

If any are found, the ripcord should be replaced. If not,

the cable can be straightened and returned to service.

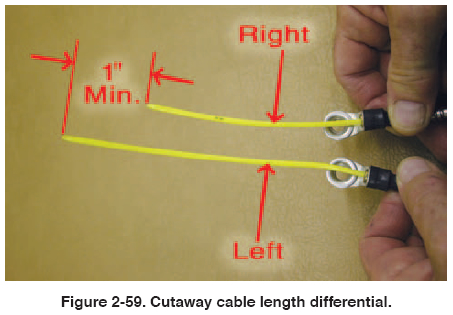

With the single side RSL, it is imperative that the main

riser with the RSL attachment leave after the opposite

riser. If the opposite riser stays connected while the

RSL deploys the reserve, there is the possibility of a

main/reserve entanglement. To ensure the correct staging of the cutaway, the release cable of the RSL side must be

longer than the cable on the opposite riser. A minimum of

1" is the standard differential. [Figure 2-59]

|