Chapter 2

HARNESS/CONTAINER

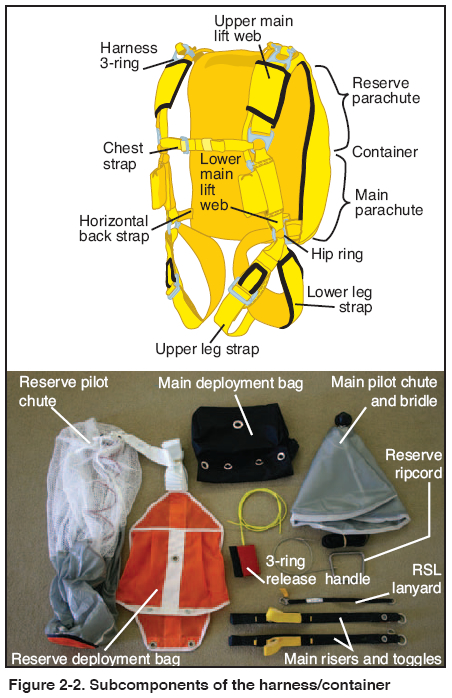

The harness and container assembly includes all the

remaining parts necessary to complete an airworthy parachute

system except for the canopies. The basic harness/

container assembly is what remains when all items

that can be removed without unstitching have been

removed. Most sport parachute assemblies have the harness

and containers integrated into one assembly, but

many military assemblies may be disassembled into separate

harness and container subassemblies. The following items are subcomponents of the harness/container assembly

and are shown in figure 2-2.

PILOT CHUTES AND BRIDLES FOR THE

MAIN AND RESERVE PARACHUTES

The pilot chute is a small parachute or similar device,

which enters the airstream when released to act as a drag

device and withdraw the canopy from the container. As

such, it maintains tension on the canopy and lines during

the deployment process. Pilot chutes are either springloaded

or manually thrown into the airstream as a “hand

deployed” pilot chute. Some military or emergency pilot

chutes are ballistically deployed. A bridle is a piece of

line or webbing that connects the canopy or deployment

device to the pilot chute.

RIPCORDS OR EQUIVALENT DEVICES FOR

THE MAIN AND RESERVE PARACHUTES

The ripcord is a device for securing the container closed

prior to use. It usually consists of a handle, a flexible

cable, one or more pins, and a device for securing the

cable to the handle. Some modern ripcords use a stiffened

cable instead of a pin.

DEPLOYMENT DEVICES FOR THE MAIN

AND RESERVE PARACHUTES

Deployment devices are designed to provide an orderly

and controlled deployment of the parachute during use. Typical devices include bags, sleeves, pockets, straps,

and sliders.

MAIN PARACHUTE RELEASE MECHANISM AND ASSOCIATED HANDLES OR STATIC LINES

The main parachute release mechanism has two parts.

One part is attached to the harness and the other to the

risers. These types may utilize a separate release handle.

In addition, the reserve may employ a static line to

activate it.

RISERS, MAIN OR RESERVE,WHEN NOT INTEGRAL WITH THE HARNESS OR CANOPY, AND THEIR ASSOCIATED STEERING TOGGLES

Risers are part of the suspension system between

the lines and the harness or load. Generally made

of webbing, emergency parachutes usually have the risers

integral to the harness. Risers used on sport or military

systems used for intentional jumping have release

mechanisms installed. Steering toggles are usually

design specific to the riser for the type of canopy

installed.

OTHER HARNESS/CONTAINER ASSEMBLY

COMPONENTS

Other components designed to function as part of the

harness/container assembly, such as closing loops, also

may be used. Closing loops used with automatic activation

devices (AADs) on reserve or emergency parachutes

are usually design specific to ensure proper operation of

the system.

TSO STANDARDS

The original TSO C23b for parachutes came into existence

in 1949. The specifications were revised in 1984 to

C23c and again in 1994 to C23d. The TSO is a simple

two-page document that specifies the requirements for

certification. This document also references a performance

standard that the parachute must meet. C23b parachutes

were tested to standards under National Aircraft

Standards Specifications NAS-804. When the TSO was

revised in 1984, the specification document was drafted

under the auspices of the Society of Automotive

Engineers (SAE) S-17 committee as Aerospace Standard

AS-8015. When the TSO was revised again in 1994, the

revised document became AS-8015b with the original as

AS-8015a. Figure 2-3 is a table showing the pertinent

points of each of the TSO certifications. For a more thorough

study of the documents, refer to Appendix I.

The TSO system consists of two parts. The first is the performance

standards listed above. This ensures that the

parachute will perform as specified. The second is the

production approval, which ensures that the manufacturer

is able to produce the parachute as designed and tested.

While minor design changes are allowed, any major

design change must be submitted to the FAA for approvalbefore implementation. A major change is any that will

affect the fit, form, or function of the parachute.

For the aspiring rigger, the primary purpose of knowing

the TSO system is determining the compatibility of components

when assembling the parachute system. This is

necessary in order to ensure that, besides fitting together

properly, the performance standards are compatible.

Under Advisory Circular (AC) 105-2—Sport Parachute

Jumping, “the assembly or mating of separately approved

components may be made by a certificated and appropriately

rated parachute rigger or parachute loft in accordance

with the manufacturer’s instructions and without

further authorization by the manufacturer or the FAA.”

Under these guidelines, there are certain parameters that

must be met. One of them is to ensure that “the strength

of the harness must always be equal to or greater than the

maximum force generated by the canopy during the certification

tests.” Full knowledge of the TSO documents

ensures that the above requirements are met.

|