Chapter 2

MODERN DESIGN CONCEPTS

The containers of today do more than simply enclose

the canopy and deployment device. Sport containers in

particular need to be designed so that they contribute to

the deployment needs of the specific parachute.

Piggyback designs have separate requirements for the

main and reserve containers.

The reserve container is generally small, tight, and

mostly wedge-shaped. Virtually all popular sport systems

are designed around the use of a ram-air canopy. The

deployment method of choice is a Type 5 deployment

bag. In the early days of the ram-air reserve, there were

certain container design requirements specified by the

manufacturer. These were:

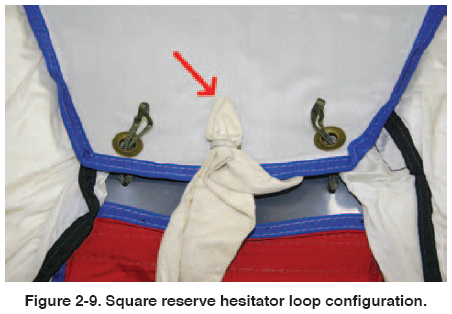

1. A hesitator loop configuration secures the bridle and

holds the bag in until the reserve pilot chute is

deployed and under drag. [Figure 2-9]

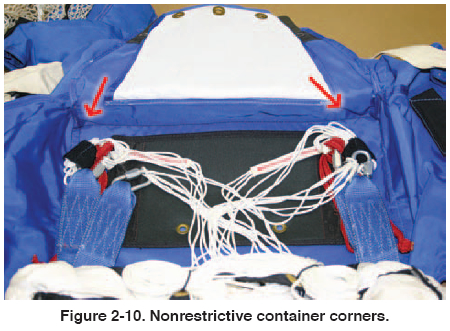

2. Nonrestrictive corners to allow the bag to be lifted

off by the bridle in the event of a horseshoe-type

malfunction. [Figure 2-10]

These requirements were adhered to for many years.

Today, containers achieve the required holding and

deployment needs through design tailoring. The bottom

corners of the reserve container are designed so that the

bag is held in place while the pilot chute and bridle deploy

and then releases the bag to the airstream. At the same

time, the bag can still deploy quickly in the event of a

horseshoe-type malfunction.

The main container is less restrictive than the reserve in

holding the main canopy in place during deployment.

This is important so that there is no tendency for the bag

to twist or be unstable on deployment. With many of the

main canopies used today, if the bag is unstable, it results

in the main canopy opening unevenly and causing spins

and possible malfunctions. Along with the main bag, the

main risers must be able to deploy evenly for the same

reasons.

In the early days of skydiving, the primary body position

was a stable, face-to-earth position. This resulted in the

main container being behind the parachutist out of the airflow.

One of the primary problems faced during those

days was the high incidence of pilot chute hesitations.

This was the result of the container designs and the relatively

poor performance of the available pilot chutes. The

advent of the hand deploy pilot chutes reduced the incidence

of hesitations.

In the face-to-earth position, the primary purpose of the

container is to hold the canopy and pilot chute closed and

then allow it to open during deployment. Today, body

positions experienced during free fall range from headdown

to feet-to-earth and everything in between. Where

speeds formerly experienced ranged from 110 mph to

maybe 140 mph, today speeds in a head-down position

can exceed 200 mph. This has changed the container

dynamics to ensure a more secure system and increased

protection from the wind blast. These changes have

resulted in more secure and streamlined configurations to

accommodate these new requirements. Figure 2-11 shows

a modern container design shaped to meet the high-speed

airflows of today.

An additional area that needs to be addressed when

designing piggyback systems is the main riser covers. In

the early days of sport piggyback designs, the main risers

were held in position by webbing keepers. As the sport

progressed, the use of fully enclosed main riser covers

became the norm. In their attempt to protect the main risers

during high-speed free fall, some designs tend to

restrict the deployment of the reserve container in the

event of a “total” main pack malfunction. When this happens

and the main container remains closed, the main

riser covers do not open. Because of this, there is additional

restriction over the upper corners of the reserve

container. This contributes to higher reserve bag release

forces when deployed. In severe cases, this can result in a reserve pilot chute in tow with potential serious consequences.

The balance between sufficient main riser protection

and the need for full reserve deployment freedom

can be an important design feature.

|