Chapter 2

HARNESS DESIGN

According to Poynter’s Parachute Manual, “the harness

is an arrangement of cotton, linen, nylon, or Dacron®

webbing, which is designed to conform to the shape of

the load (usually the body) to be carried in order to secure

it properly so that the opening forces and the weight of

the load are evenly distributed during opening and

descent.”

The earliest harness was nothing more than a swing seat

that the parachutist sat on and then held onto the risers

or suspension straps. It soon became apparent that if the

openings were anywhere uneven, it could be very precarious

for the parachutist. While the sling seat worked

for the ride down, it was necessary to add additional

straps to secure the parachutist. These straps included

the leg, back, and chest straps. The standard harness

configuration is equipped to secure a torso, head, arms

and legs with straps. Others have been added over time for additional purposes such as survival kits or cushions.

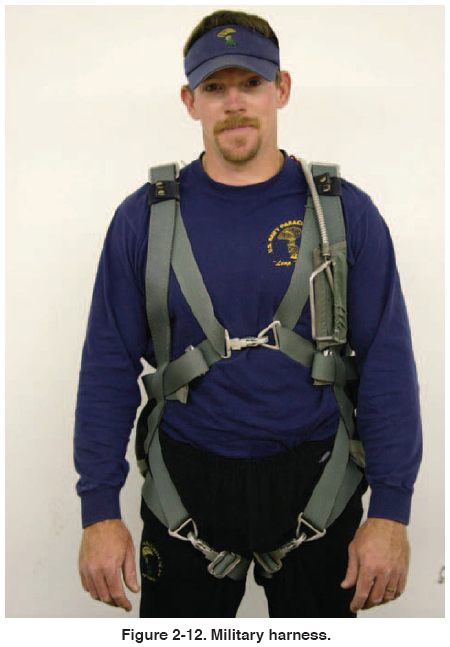

Figure 2-12 shows a basic military style harness. This

harness configuration has seven points of adjustment to

allow fitting of most military personnel.

Most of the early parachute systems had the harness

detachable from the containers. This allowed interchangeability

for various models. In the 1970s, skydiving

systems began to integrate the harness into a true harness/

container assembly. This was accomplished by

sandwiching the harness between the container and

backpad and sewing them together. Figure 2-13 shows

one of the earliest custom systems called the “Super

Swooper.” This harness was the precursor of today’s sport

harnesses.

As skydiving and the sport parachute industry has grown,

most of the equipment is now custom-built for each individual.

The standard piggyback harness configuration of

today is a fixed main lift web with adjustments only at

the chest and leg straps. [Figure 2-14] Elimination of the

extra hardware and webbing has resulted in a dramatic

reduction in weight of modern systems. Along with this

has been an increase in comfort and flexibility. One of

the most innovative designs adopted in recent years is the

“articulated” harness. This design incorporates metal

rings at the hip junction and the chest-strap attachment. [Figure 2-15] These rings allow a full range of motion both in the air and on the ground and increase the fit and

comfort of the harness. An added benefit is that this style

of harness is stronger under high shock loads. This is due

to the natural alignment of the webbing during the opening

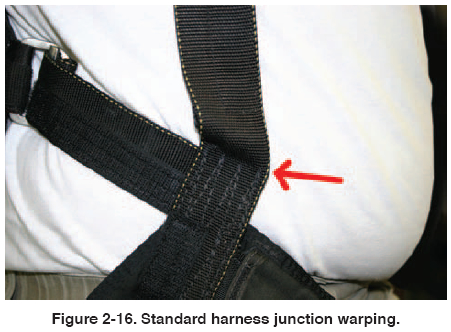

process. With a nonarticulated harness, the webbing

junctions warp and load unevenly. [Figure 2-16] Because

of this, point loading occurs, stitching breaks, and the

junction can fail with disastrous results.

both in the air and on the ground and increase the fit and

comfort of the harness. An added benefit is that this style

of harness is stronger under high shock loads. This is due

to the natural alignment of the webbing during the opening

process. With a nonarticulated harness, the webbing

junctions warp and load unevenly. [Figure 2-16] Because

of this, point loading occurs, stitching breaks, and the

junction can fail with disastrous results.

In recent years and with the increasing popularity of vertical

skydiving or “freeflying,” greater speeds are experienced with corresponding higher loads on the harnesses.

For many years, harnesses were overbuilt as they were

basically copies of military designs. As the sport has progressed,

equipment has been made lighter and smaller.

|