|

The correct identification and use of the various materials

in parachute manufacturing and repair are of vital

importance to all riggers. Just as important as acquiring

knowledge of tools and machines, the language of materials

is a necessary part of a rigger’s job comprehension. In

doing repairs or alterations, the rigger must be able to

identify the types of materials used in order to duplicate

the original manufacture or ensure the correct level of

safety necessary. Some materials may look similar, but

there can be subtle differences between them that make a

major difference in their strength or durability.

It is not the intent of this chapter to present information

on every type of material or hardware ever used in parachutes.

For those materials used in obsolete or military

surplus parachutes, there are reference sources, such as

The Parachute Manual by Poynter, for the rigger to use to

identify older materials. The intent of this chapter is to

present as much information as possible on the modern

materials used in today’s parachute systems.

Most riggers operate quite successfully at a basic level of

material knowledge. There are certain materials that are

in common use on most parachute systems, and in dealing

with these on a regular basis, the rigger becomes very

familiar with their use and characteristics. It is necessary

that the rigger know their correct type, nomenclature,

strength, and common use. In dealing with other riggers,

manufacturers, and suppliers, the rigger is then able to

identify the referenced material in order to obtain the

appropriate repair part or describe the use of the material

to others. All of this is part of the parachute “language”

required for the rigger to operate under.

SPECIFICATIONS

All certificated parachute systems built under

Government approval programs require most, if not all,

materials used in their construction to have some form of

specification approval. The most common of these systems

is the military specification (MIL-SPEC) system.

In addition, there are other Government specifications,

such as Federal Standards, and commercial specifications

in use. The MIL-SPEC system is the one with which most

riggers are familiar. Contrary to popular perception, not

all materials for use in parachute manufacturing must be

MIL-SPEC. Any specification may be used, providing the

manufacturer can prove compliance with this specification,

and that the specification is acceptable to the FAA

for use in the parachute system. As a rule, the MIL-SPEC system has proven the most readily available and

accepted method.

In recent years, the Government has been accepting more

commercial specifications in lieu of MIL-SPEC items. In

2002, the Parachute Industry Association (PIA) adopted

approximately 270 parachute related specifications,

drawings, standards, and test methods. The PIA takes

responsibility for the continued maintenance and revision

of these specifications. As the specifications are revised,

they keep their original identification number, but the PIA

prefix precedes them. For instance, MIL-W-4088 webbing

becomes PIA-W-4088. Through the involvement of

the PIA Specifications Committee, the revised specifications,

including new digital drawings, are made available

to the industry.

The MIL-SPEC or PIA-SPEC system of identification

consists of the initial letters MIL or PIA with a middle

letter such as W for webbing or wire, then the identification

or serial number of the specification. In addition,

there may be a revision letter such as A, B, C, D, etc. In

the case of PIA-W-4088D, this is the fourth revision.

The materials and hardware listed herein are only a small

part of those available but the most commonly used in the

majority of today’s rigging profession. By learning the

specifications and uses of these materials, the rigger

establishes a sound basis for the repair and maintenance

of modern parachutes.

To promote the latest specifications, the PIA nomenclature

is called out unless otherwise noted. In the past, the common

method to denote the various types of webbings,

cords, etc., was to use the Roman numeral for the type (i.e.,

Type VIII for Ty-8, Type XVII for Ty-17, etc.). For this

book, the standard is the Arabic numeral (i.e., Ty-7, etc.).

Many of the figures in this chapter use a neutral background

with an XY grid for reference. The numbers are

one-inch increments for a proportional reference.

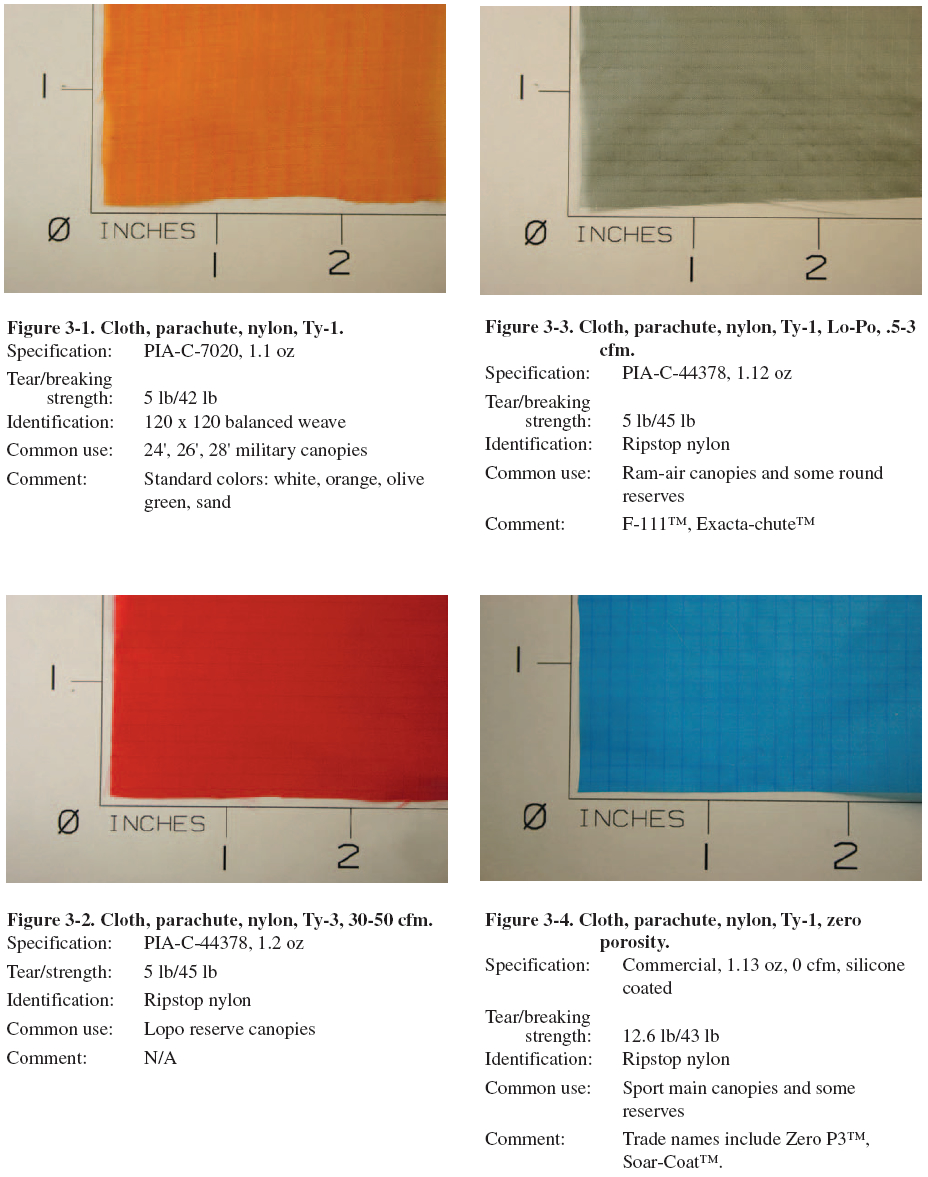

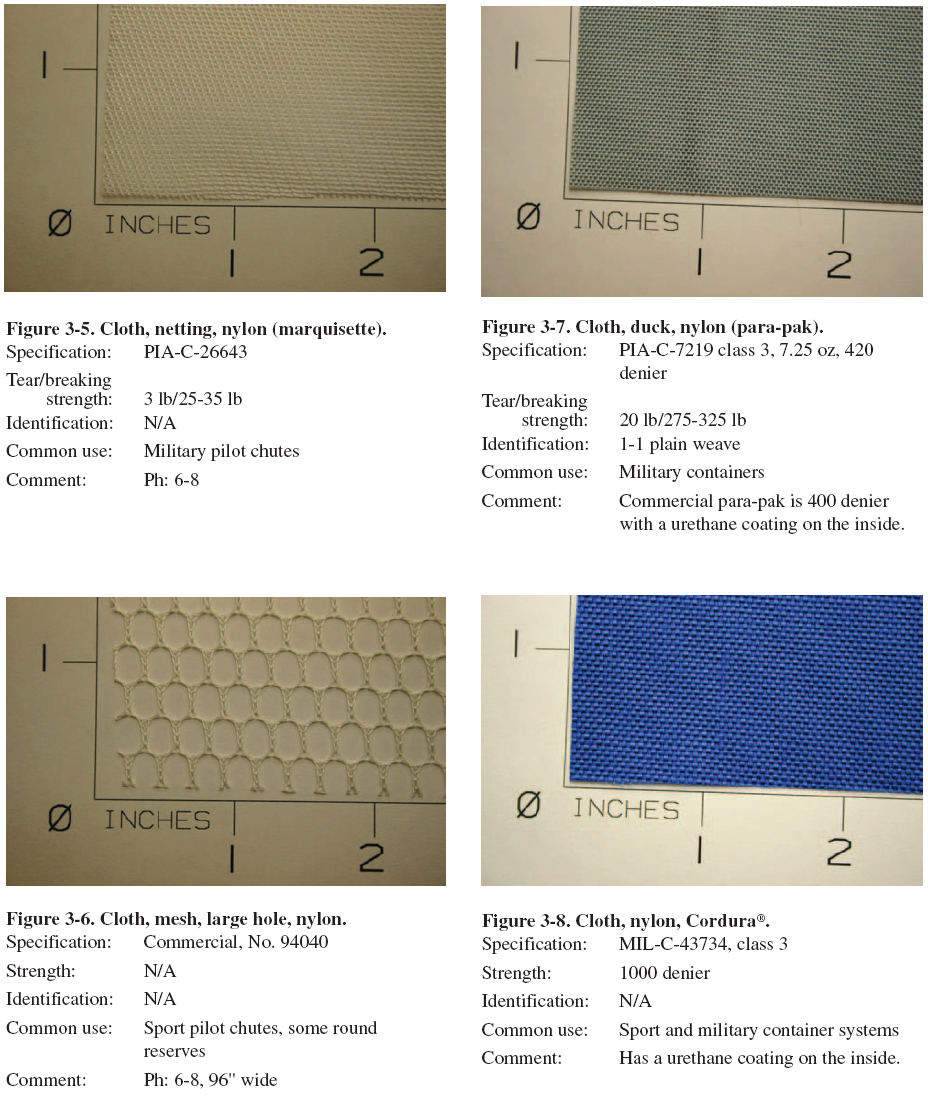

FABRICS

Fabrics for use in the manufacturing of parachutes are

predominately nylon. The major differences include the

weave, weight, and finish. The various types of materials

include canopy fabric, pack cloths, mesh, elastic fabrics,

stiffener materials, and foams.

Canopy fabrics are primarily ripstop nylon. Ripstop

weave is a plain weave with heavier threads woven into

the material resulting in a boxlike pattern. The heavier

thread inhibits the tearing process and results in stronger

fabrics. [Figures 3-1 through 3-6]

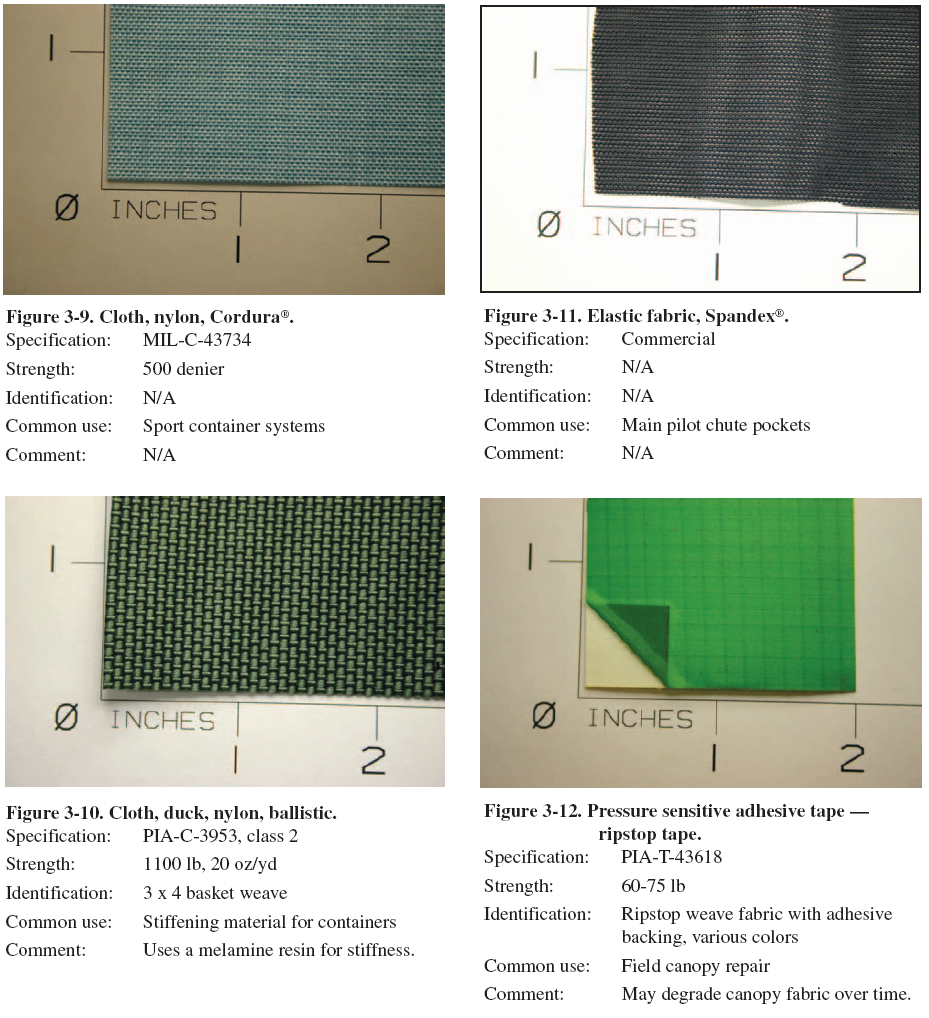

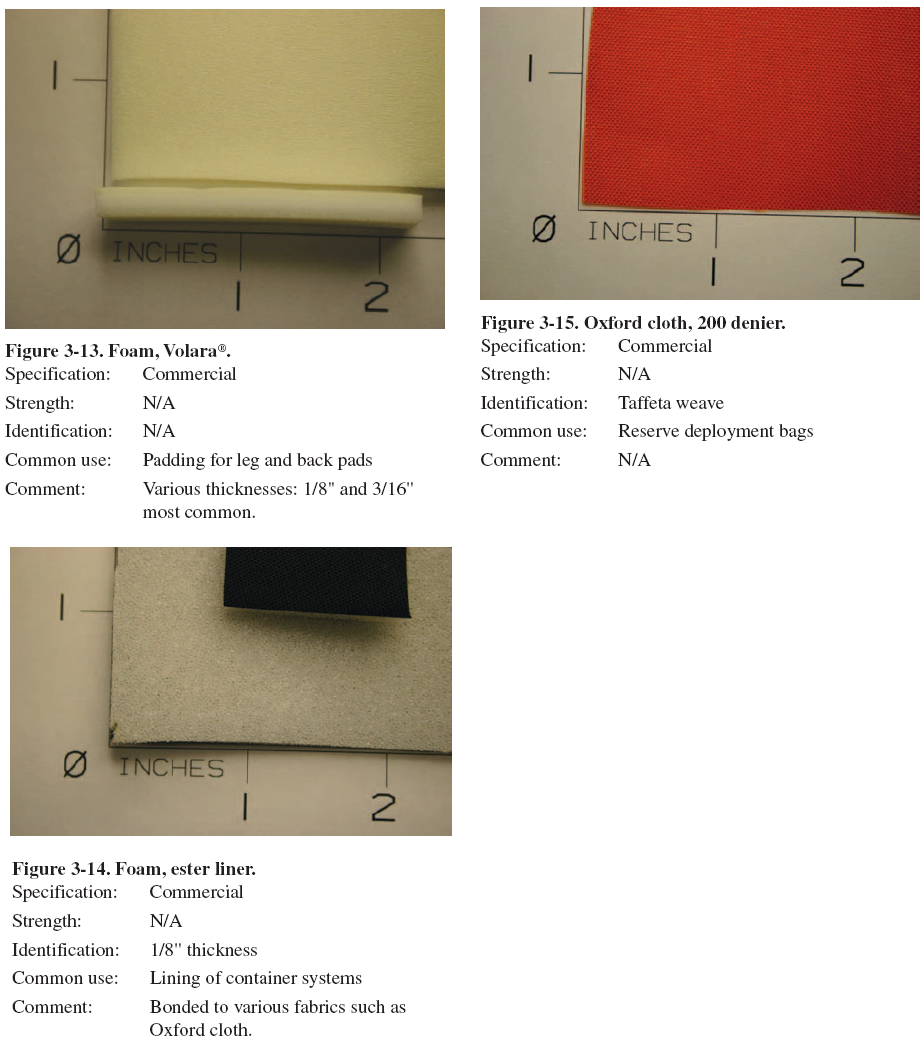

The composition of most containers is from either nylon

duck (para-pak) for military systems or Cordura® for

sport systems. Most sport containers also utilize a thin

foam lining on the inside of the flaps to smooth out the

fabric and absorb wear and tear. Other fabrics, such as

mesh, Spandex®, and ballistic fabric, serve specialized

purposes. [Figures 3-7 through 3-15]

|