Chapter 3

HARDWARE

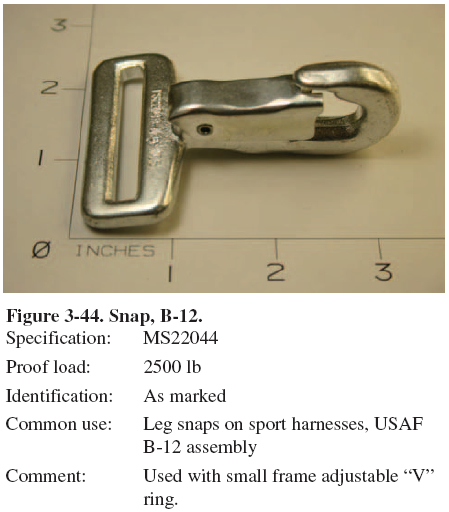

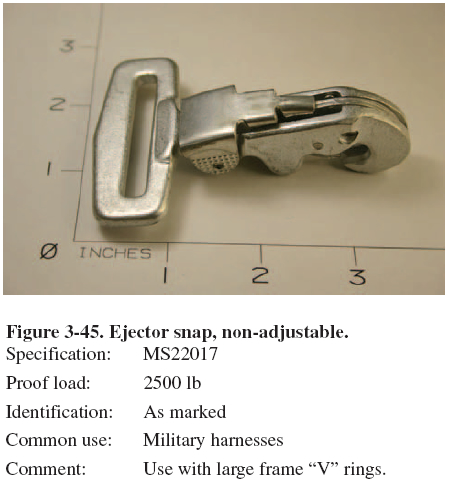

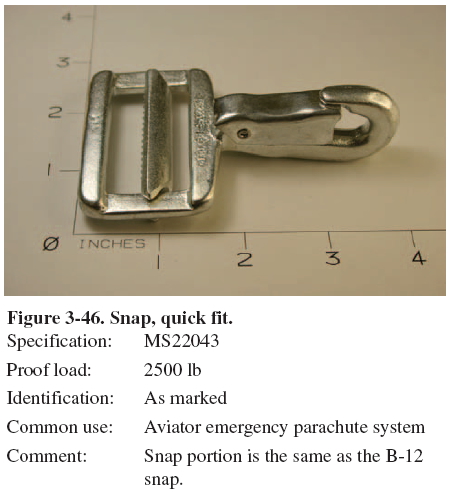

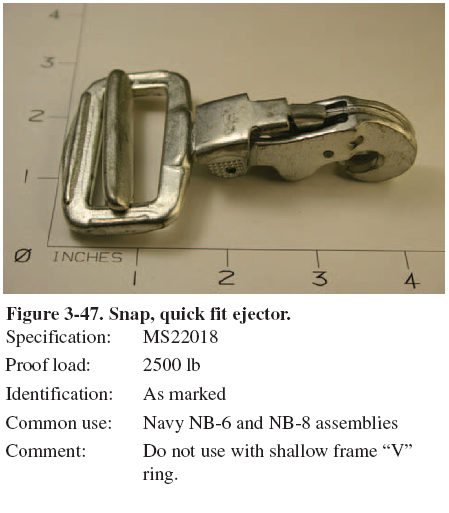

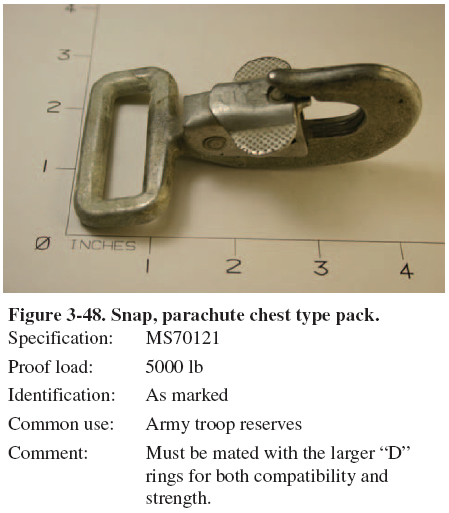

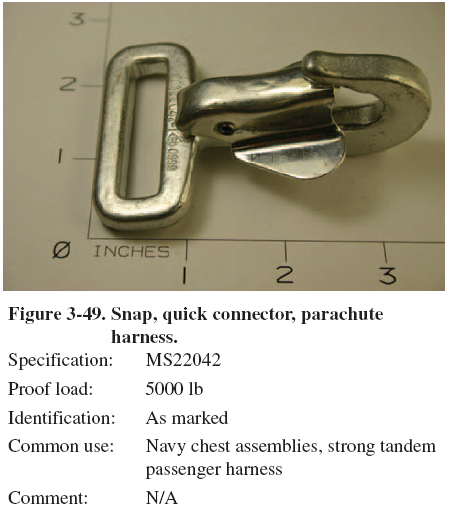

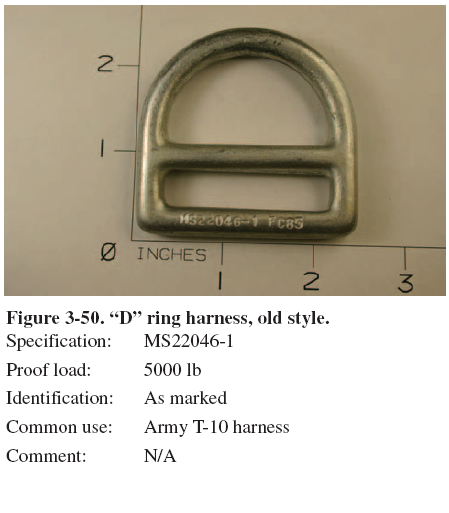

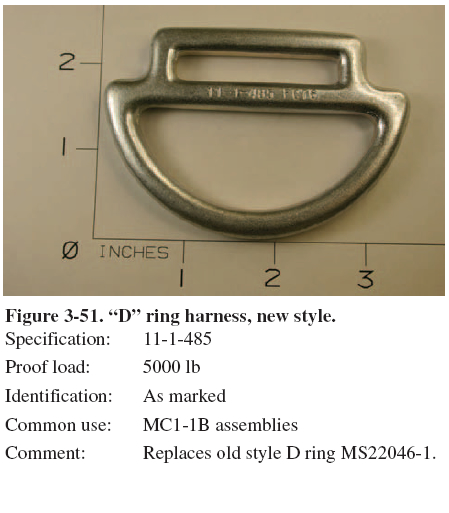

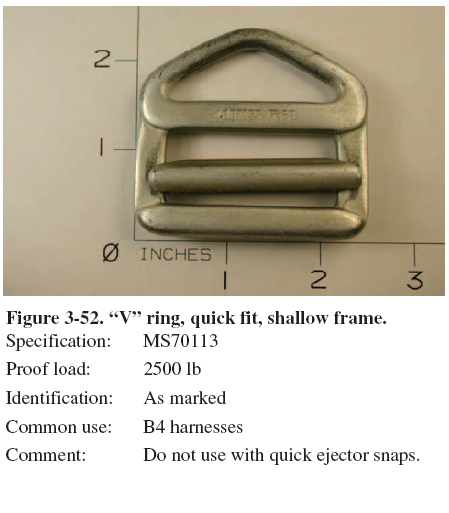

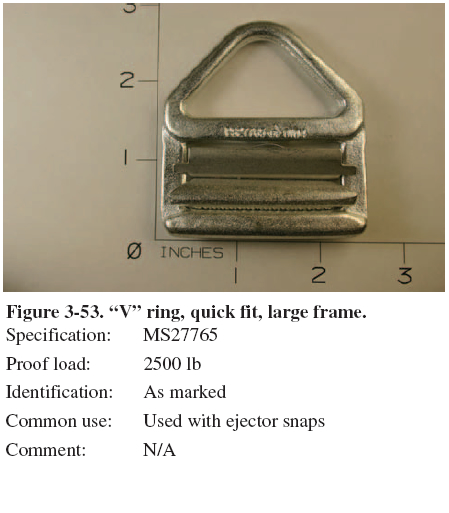

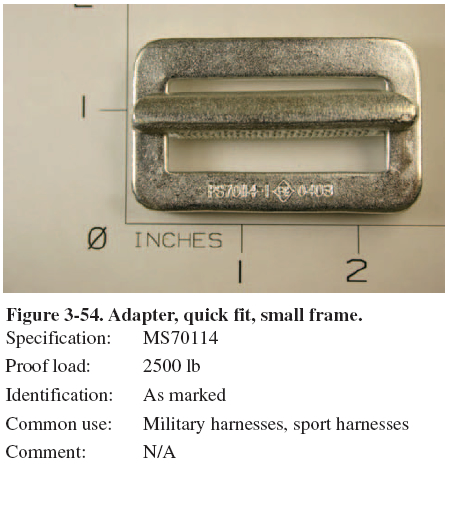

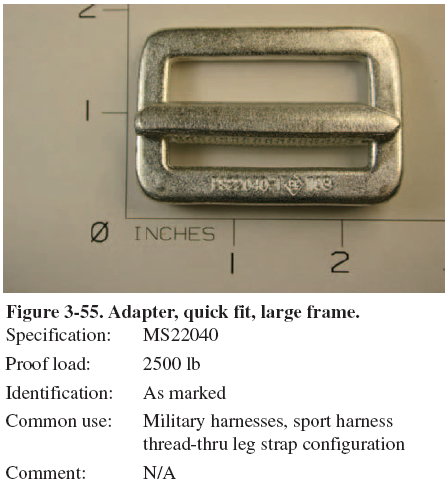

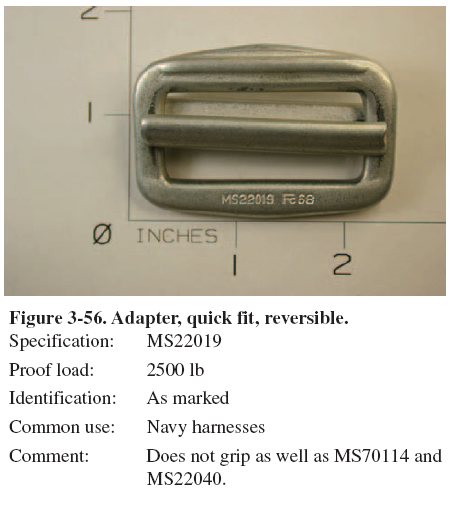

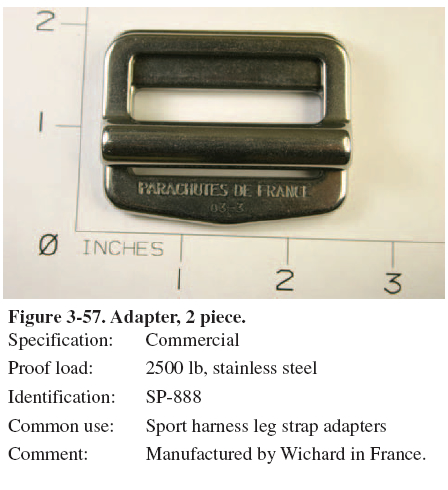

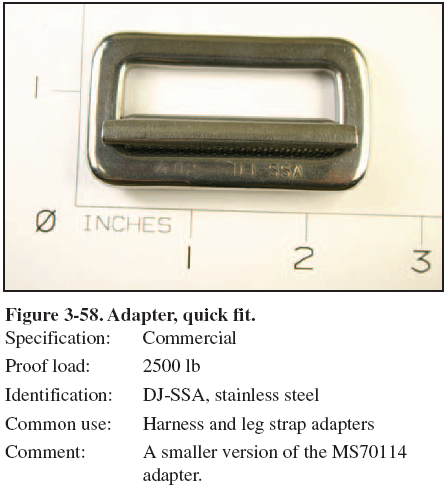

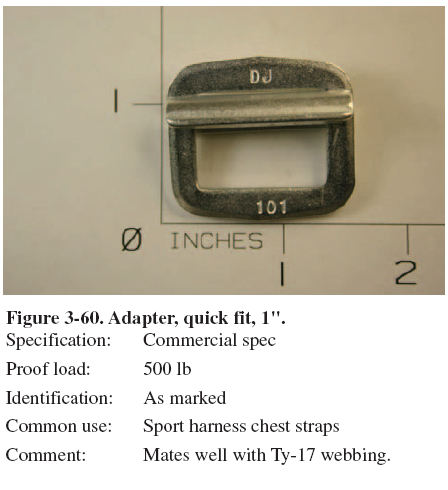

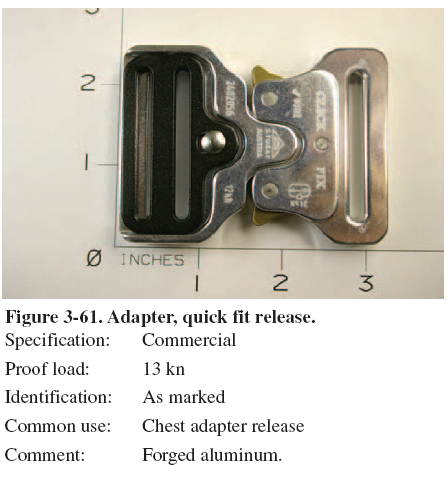

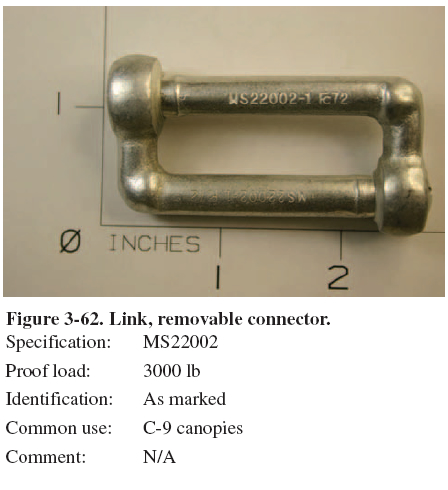

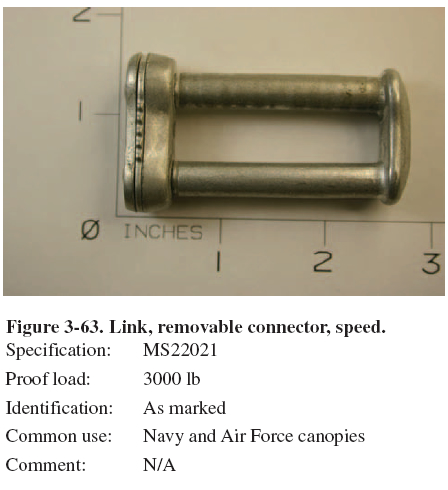

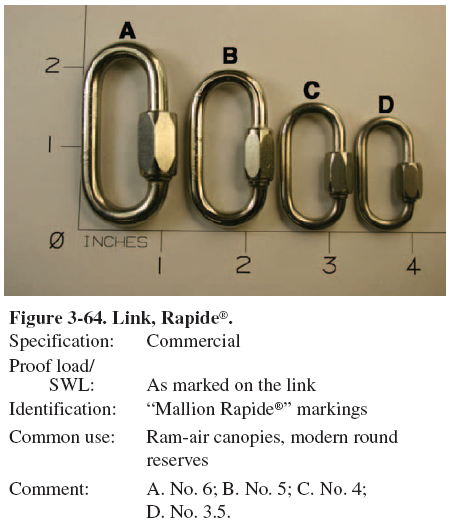

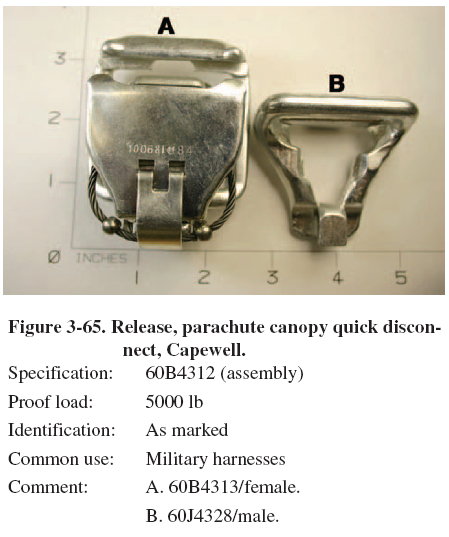

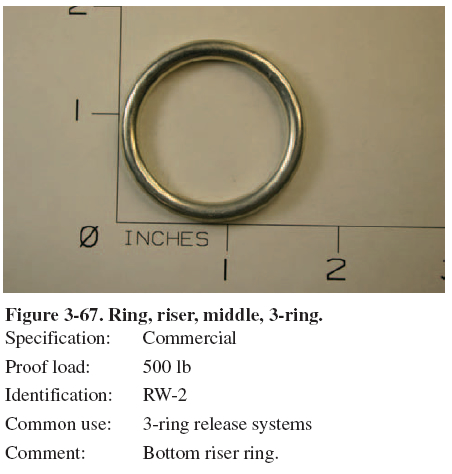

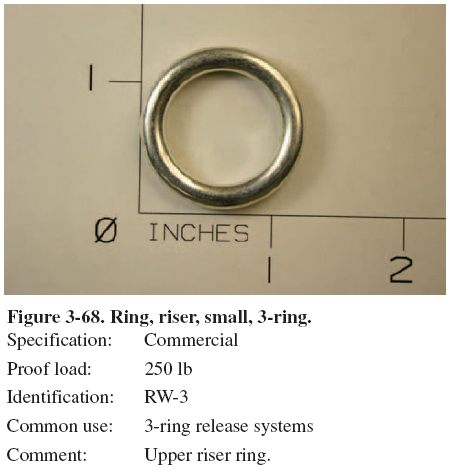

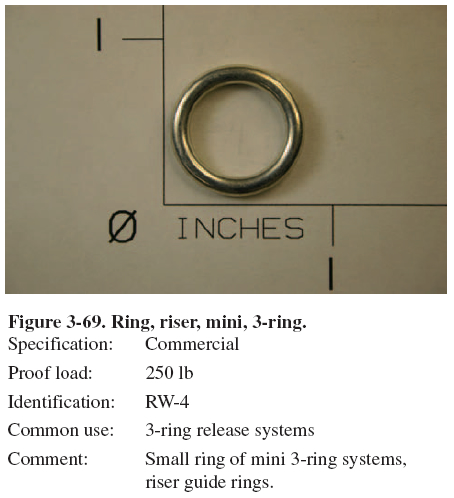

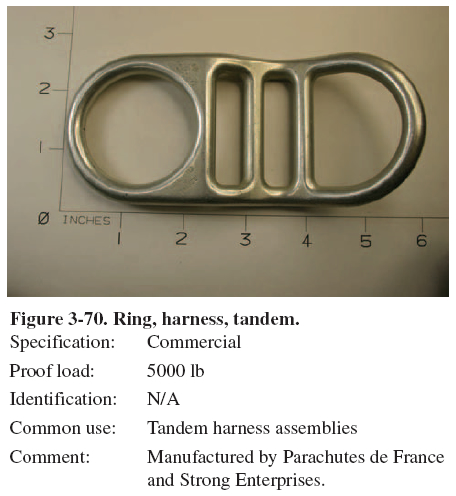

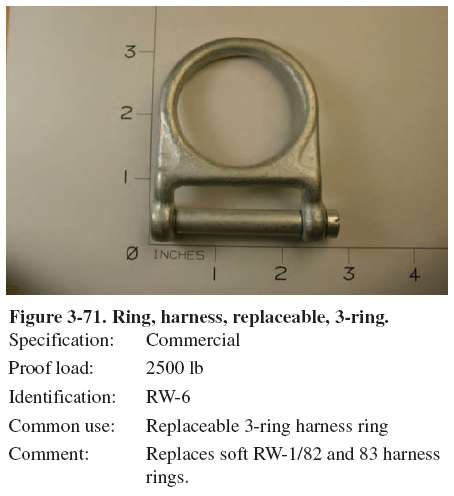

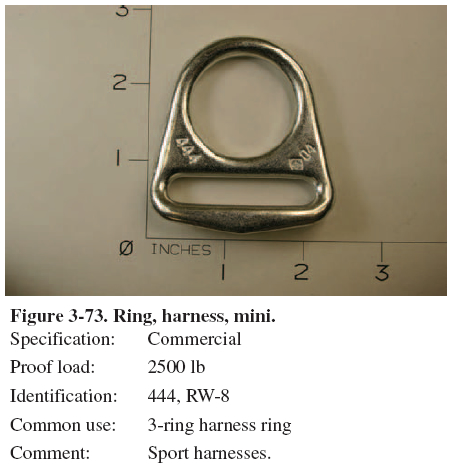

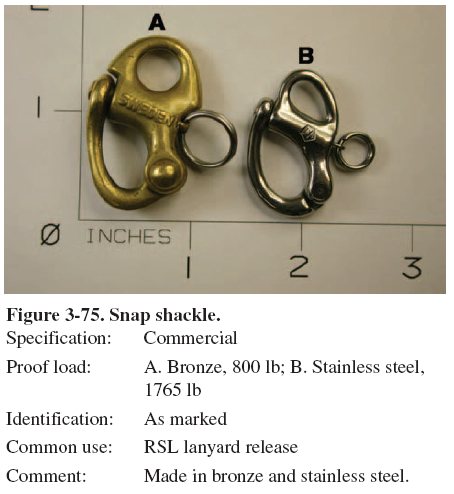

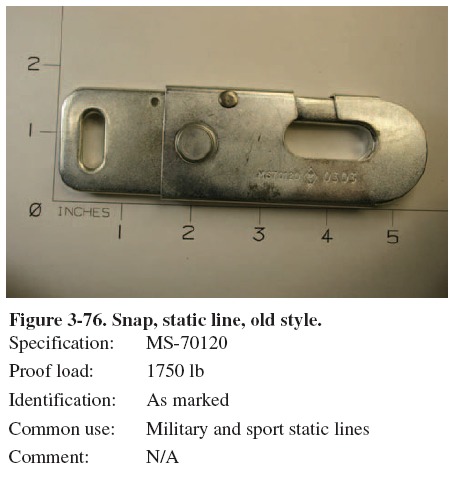

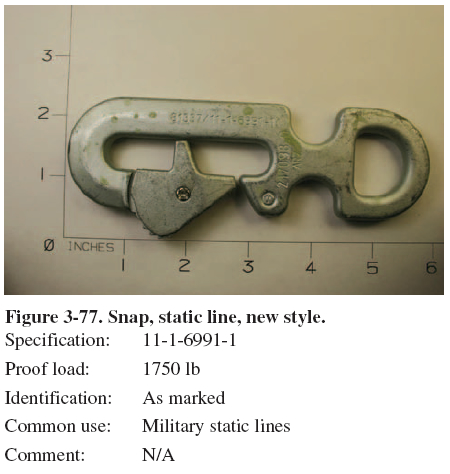

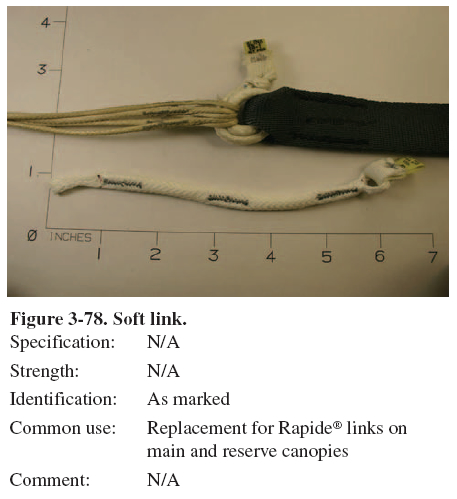

Hardware, as defined in the context of parachutes, is “all

metal parts associated with parachutes, their systems, and

their suspended loads.” Most riggers identify hardware as

the snaps, adapters, rings, links, and releases commonly

used on harnesses. In addition to these components, other

hardware includes items such as lightweight links and

snaps, ripcords and handles, stiffeners, grommets,

springs, and snap fasteners. [Figures 3-44 through 3-78]

Most load bearing hardware consists of drop forged alloy

steel, sheet alloy steel, or forged aluminum alloy.

Lightweight hardware may be stamped from the sheet

alloy steel, or in rare instances, cast. The majority of the

load bearing hardware is forged carbon steel with either

cadmium or zinc plating.

In recent years, there has been a movement to produce

newer design hardware of stainless steel. This removes

the problem of plating and the environmental problems

associated with it. However, stainless is harder on the

forging dies and the finishing processes take longer.

Consequently, stainless hardware is generally more

expensive than carbon steel.

All specification hardware has the appropriate number

stamped or marked on it. The MS prefix is on those with

the MIL-SPEC certification. All with the newer PIA certification

have the mark with the PS (Parachute Standards)

prefix. [Figure 3-43] Most of the current hardware has the

mark with the MS prefix. As current stocks deplete, the

mark on new production is with the PS prefix.

|