Chapter 4

DEPLOYMENT AND INFLATION CHARACTERISTICS

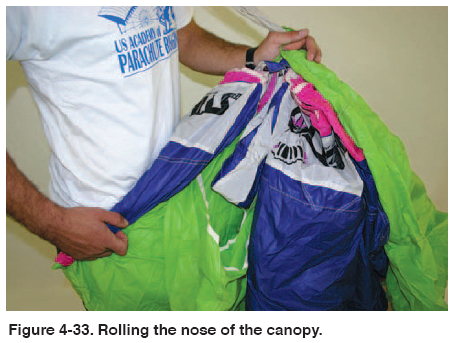

Main canopies have changed dramatically over the last

several years and, consequently, different opening

problems have emerged. One of the most common

problems encountered is hard openings. The most

effective method employed to reduce hard openings is

to roll the nose of the canopy to close off the openings

in the leading edge during the initial inflation process.

This rolling technique varies from a single roll to several

rolls. Figure 4-33 shows this technique. If this does

not solve the opening problem, riggers should contact

the manufacturer for advice. Most manufacturers are

very cooperative and have considerable expertise in

working with their products.

In the event the manufacturer cannot resolve the problem,

it may be necessary for the rigger to modify the

slider size, or deployment brake settings. Of these

options, the easiest to do is to change the brake setting.

Reducing the brake setting results in less pressure on

the canopy during opening, thereby reducing the opening

force. The negative effect of reducing the brake setting

is an increase in opening surge. The new brake

setting must find the balance of these results that best

fit the user. If changing the brake setting does not work,

then the rigger may wish to increase the size of the

slider to slow the openings. This usually means replacing

the slider with a larger one. This has the effect of

increasing the drag on the slider and restricting the

canopy inflation.

As canopies age and accumulate substantial jumps on

them, many begin to develop slow openings, commonly

known as “sniveling.” If the canopy was originally

packed with the nose rolled, reducing the number

of rolls may speed up the openings. However, many

times the slow openings are due to other causes. One

of the most common is the canopy getting out of trim

due to the stretch of the suspension lines. The rigger

should check the trim of the canopy against the manufacturer’s

specifications and either re-trim the canopy or re-line it. This has a pronounced effect of improving

the openings as well as the flying characteristics, particularly

on canopies made from zero porosity (ZP)

fabric.

The effect on fabric that originally had a porosity (permeability)

of 0-3 cfm or 0-5 cfm, such as PIA-C-

44378, may not be as dramatic. With these canopies,

changing the brake setting and increasing it by pulling

down the tail will speed up the inflation of the canopy.

The rigger must be careful not to set the brakes so

deeply as to place the canopy in a stall during opening.

If this does not work, then decreasing the size of the

slider or the fabric type of the slider may help speed up

the openings. Some of these problems, while appearing

to be main canopy related, are traceable to other

components of the parachute system such as the

deployment bag, bridle, or pilot chute.

MAIN PILOT CHUTE

Hand deploy pilot chutes are generally made from

either the PIA-C-44378 (F-111) fabric or more commonly,

zero porosity (ZP) fabric. The PIA-C-44378

fabric begins as a very low porosity fabric but as it is

used, the permeability increases. As this happens, the

drag of the pilot chute decreases. Consequently, the

ability of the pilot chute to lift the weight of the canopy

decreases and the speed of the opening is affected.

Experience has shown that pilot chutes made from this

type of fabric exhibit a decrease in performance at

around 500 jumps under normal use.

Pilot chutes made from the ZP fabric last considerably

longer than those made from F-111. However, there

has been some disagreement concerning the use of the

two different fabrics in pilot chutes. One canopy manufacturer

advocates the use of F-111 type fabric only.

They believe the ZP fabric contributes to hard openings.

Most parachutists like ZP pilot chutes because

they last longer.

The size of the pilot chute has a direct correlation to

the type of opening experienced. In the early days of

hand deploy chutes, a 36" F-111 pilot chute was standard

on most systems. As the canopies became smaller

and lighter, pilot chutes became smaller as well. Today,

24-26", 30", and 33" pilot chutes are all common.

Several factors dictate the size of the pilot chute used.

The first is the weight of the canopy. Another factor is

the main container closing configuration. Some systems

are designed to hold the deployment bag so securely that

it literally has to be jerked from the container. This type

requires a larger pilot chute than the type of container

that allows unrestricted extraction of the bag. This same

problem can develop when an individual packs an oversized

main canopy into the main container. Usually, a

larger deployment bag is needed to hold the additional volume. When the bag is forcibly stuffed into the container,

the bag can be restricted from being pulled

smoothly from the container.

If the pilot chute is too small, a pilot chute in tow can

result. If the parachutist puts a larger pilot chute on the

system, the bag can be extracted from the container,

but the increased size of the pilot chute contributes to

increased snatch force during the opening sequence.

This results in perceived hard openings. Therefore, the

size of the pilot chute and the deployment bag can have

considerable effect on the opening characteristics of

the main parachute.

|