Chapter 4

BRIDLE LENGTH

The length of the bridle has an effect primarily on the

deployment of the main pilot chute. The bridle must be

long enough to place the deployed pilot chute past the

turbulence caused by the parachutist. If the bridle is

too short, the pilot chute will stay in the parachutist’s

burble. The length of the bridle from the locking pin to

the pilot chute averages around 7 feet. Recent years

have seen the growth of the use of the “Birdman” flying

suits. Because of the increased surface area and the

decreased free fall speeds, the use of a longer bridle

has become common, with a 9-foot length working

well. Along with the longer bridle, containers have

been modified to allow the bottom to open fully and

the main bag to be extracted rearward towards the feet

due to the more horizontal trajectory of the parachutist.

RUBBER BANDS

The rubber stow bands play an important part of the

deployment sequence, and serve two important functions.

First, they hold the mouth of the deployment bag

closed and prevent premature deployment of the main

canopy. Secondly, they hold the line stows securely to

allow a clean, orderly deployment of the lines. With

the advent of smaller diameter lines, such as 550

Spectra® and HMA®, smaller diameter rubber bands

have been developed to properly secure these lines. If

the smaller rubber bands are not available, many parachutists

double stow the larger rubber bands around the

small lines. There are other products such as Tube

Stoes®, which are designed to replace rubber bands

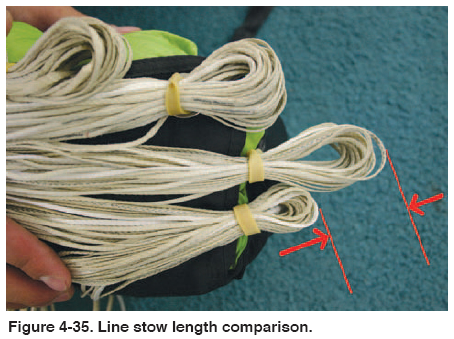

and last longer. Figure 4-34 shows the various rubber

bands and Tube Stoes®. In addition to the correct rubber

bands, the length of the line stows is important as

well. In the past, 1" stows were common, but today, 3"

stows are recommended by several manufacturers.

Figure 4-35 shows the comparison between the two

lengths. The main point to remember is that the lines

must be stowed neatly and securely.

ASSEMBLY OF THE MAIN CANOPY TO THE HARNESS AND CONTAINER

The rigger should be familiar with the various types of

canopy releases currently in use. In skydiving, the

most common release is the 3-ring release system. It

was originally developed in 1976 for skydiving, but

has since become the dominant release system for

intentional jumping, both civilian and military.

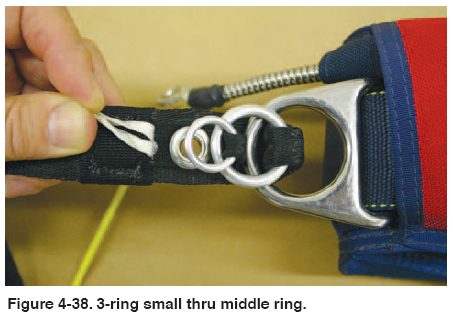

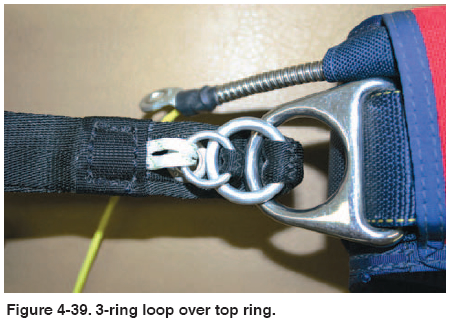

Riggers must be familiar with the assembly of the 3-ring

release since they may have to connect new canopies to

the harness and container, or have to disconnect the main

canopy to untangle it after landing. Figures 4-36 thru

4-43 show the correct assembly sequence.

The rigger must also be able to inspect the 3-ring

release to determine any wear. In particular, the following

areas need to be inspected:

• Harness 3-ring attachment. [Figure 4-44] Check for

wear on the webbing and any damage to the ring or

chipping of the plating.

• Main riser rings. Check for webbing wear, hardware

plating, grommet wear, and locking loop wear/damage.

[Figure 4-45]

• Release housings. Check for damage to terminal endings

and grommet. Check for obstructions or dirt in

housing. Check security of the housing tacking to the

harness. [Figure 4-46]

• 3-ring release handle. Check the cable for cleanliness

and cracks, and ensure that the cable ends are

sealed; inspect the Velcro® on the handle.

[Figure 4-47]

Any questions concerning the particular harness 3-ring

installation should be referred to the harness and container

manufacturer.

|