Chapter 5

CONTAINER

1. As stated in the beginning of this chapter, the initial

external inspection of the container should alert the rigger

to any damage inside. Note any holes, abrasion, or fraying

of the pack material.

2. Check the grommets for sharp edges and pulling out of

the material from under the grommet. Cones should have

the stitching secure. Check the plating on the cones in the

area of the eye. Sharp edges can cause a cone lock.

Eyelets should have the tacking secure. Snap fasteners

should be securely set in the material. Check for wear and

security of the opposing parts. Make sure that “pull-thedot”

types are set correctly for direction. Stiffeners, both

metal and plastic, should not be bent or cracked. There

should be no sharp edges. Pack opening bands (POBs),

if used, should be in good shape and not stretched out.

Make sure the hooks are in good shape, too. On the military

style POBs, it may be necessary to retack the pull tabs at the end. Metal frames, if used, should be straight. Buffers

at the corners should be in good condition. Tackings, if

used, should be secure.

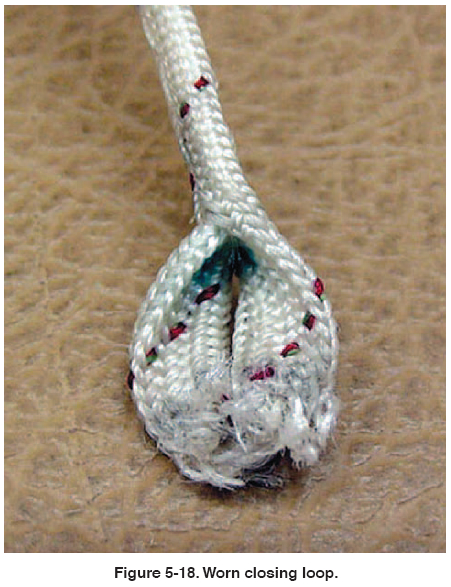

3. The container-closing loop is an extremely important

part of the container system. A worn loop may fail, which

would cause a premature opening of the container. With

the parachute still in a packed condition, check for the

correct length. If the loop is made too long or stretched

during use, the pilot chute can extend and move off center.

This may result in a poor launch or a pack job that is

uncomfortable for the user. After determining that the

loop is of the correct material and length, check the

eye(s) of the loop on the inside for wear. It is not

uncommon for the loop to appear to be in good condition

when viewed from the outside, but worn partially

through when examined from the inside. [Figure 5-18]

Many riggers simply replace the loops at each repack,

regardless of the condition.

RIPCORD

There are a number of things that need to be inspected

to approve the ripcord:

1. Check the pin(s) for straightness, smoothness,

cracks or other damage.

2. Check the cable for fraying, kinks, or severe bends.

3. Check the swage for wear and security. Look for

signs of movement on the cable.

4. Check the handle for wear, damage, rust or abuse.

Any damage or discrepancies found during the inspection

should be noted and the appropriate repair performed by

a certificated and appropriately rated rigger according to

the manufacturer’s instructions or approved manuals.

|