Chapter 5

AIRING AND DRYING

During the inspection process, the rigger must determine

the condition of the canopy and system regarding dryness

and moisture. In the “old days” it was necessary for the

parachute to be aired and dried for 24 hours prior to packing

it. According to 14 CFR, subsection 65.129(c), “No

certificated parachute rigger may pack a parachute that

has not been thoroughly dried and aired.” This determination

is at the discretion of the rigger.

RAM-AIR RESERVES AND SPORT PIGGYBACK SYSTEMS

The following inspection procedures share much with the

previous section on round canopies. The differences

between ram-air reserves and sport piggyback systems

are identified in the following section. Inspect as follows:

PILOT CHUTE AND FREE BAG/BRIDLE

1. The rigger should inspect the pilot chute in the same

manner as in the section on round canopies.

2. The free bag should be checked to include all grommets,

especially those bags that have a through loop

configuration. Any sharpness in this area can result in a

damaged closing loop. For those free bags that utilize a

Safety-Stow ® locking system, make sure the elastic loop

is of the correct size, the elastic is in good shape, and the

zigzag stitching is secure. Many riggers fabricate these

loops in the field, which, in most cases, is an unauthorized

procedure. The Safety-Stow® loop is an integral part

of the approved reserve deployment system and is manufactured

under an approved quality control system from

approved materials. The rigger should use only OEM

approved parts for this.

3. Check the bridle for any damage or wear. For those bridles

that have assistor pockets, make sure the stitching is

secure and the pockets are not damaged. Check the

Velcro® on the line stow pocket for wear and security. If

the Velcro® does not hold securely, the parachute can

experience “line dump” during deployment, possibly

causing a malfunction or out of sequence deployment.

Some deployment bags use rubber bands to stow the lines.

If this is the case, check their condition and replace them

if necessary.

4. There are still older ram-air canopies in the field that

did not use a free bag but a diaper deployment system. If

this is the case, the diaper should be inspected the same as

that on a round canopy. Be sure to use the correct type

and length of bridle, since it is generally not the same as a

round bridle.

RAM-AIR RESERVE CANOPY

Figure 5-19 shows a typical ram-air reserve and harness

and container system layout. The terminology used in

describing the parts of the ram-air canopy is called out in

PIA Technical Standard TS-100, Standardized

Nomenclature for Ram-air Inflated Gliding Parachutes,

which can be found in the Appendix I of this handbook.

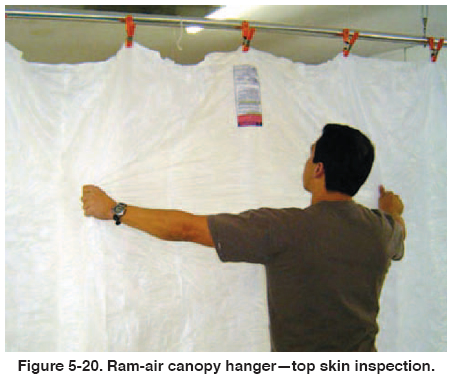

1. When inspecting and assembling ram-air canopies, begin

with the upper surface of the canopy. [Figure 5-20 on page

5-12] Work your way up and down the top panel of the cells

looking for any damage or contamination. Check the seams

for loose stitching and packing tabs if used, for security.

2. Check the trailing edge seam for secure stitching, paying

particular attention to the line attachment tapes and

their associated bar tacks. Next, look at the interior of the

cells, carefully checking the crossports for damage or

fraying of the edges of the fabric.

3. Now proceed to the lower surface of the canopy.

Carefully check all the seams and the line attachment

tapes and bar tacks.

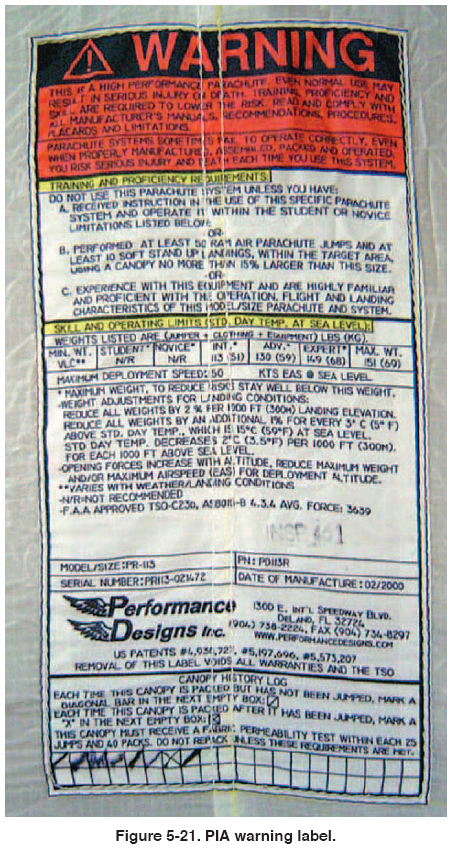

4. Some manufacturers require the use of PIA Technical

Standard TS-108, Canopy Fabric Pull Test at certain

intervals. In addition, the manufacturer’s warning/TSO

label may require that the rigger mark the label to signify

each time it is repacked and after each use. [Figure 5-21]

This label will be found on the upper surface, trailing

edge of the canopy. It is important to comply with this

requirement, not only because the manufacturer requires

it, but also it establishes the trail of use for the canopy,

which allows future riggers (and the manufacturer) to

track its use and condition over time. Some riggers feel

that they are doing their customers a favor by not marking

the boxes in order to show it has little use when it

comes to selling it. Since most individuals have a specific

rigger pack their parachute on a regular basis, it

does not take a lot of detective work to inspect the rigger’s

logbook to see how many times they have packed

any particular parachute.

|