Chapter 5

INSPECTION

1. Starting at the lower surface of the canopy, check the

line attachment loops and their associated bar tacks.

Follow the line downward to the cascade junction, if

applicable, and check the bar tack at this location.

Continue down the line to the connector links and check

the bottom loop and bar tack.

2. Starting at the top and working your way downward,

inspect the steering lines. Check all junctions and bar

tacks, paying particular attention to the brake loops.

Check the security of the steering toggles to ensure the

correct attachment method is followed. If the toggles are

improperly tied, they may come off when the jumper

deploys the brakes. Make sure the toggle matches the

size of the brake loops. If they are too large, they may

hang up and not release when needed. For compatibility,

the toggles should be those supplied with the harness

and container.

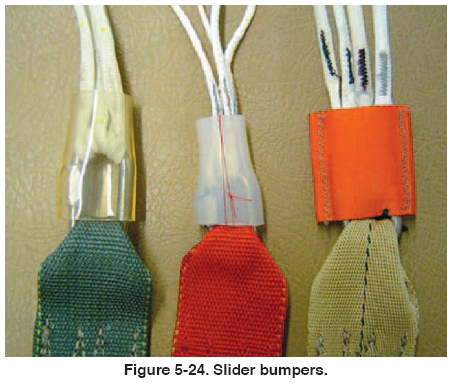

3. If Rapide® links are used on the canopy, check them as

set forth in the section on round canopies. The link orientation

and tightness will be the same. Some canopy manufacturers

provide and prescribe the use of “slider

bumpers” with their canopies. These are made from either

webbing or from vinyl or rubber tubing and are designed

to protect the grommets of the slider from impacting the

connector links during deployment. If these bumpers are

used, it is recommended that they be tacked in such a

manner that they cannot slide up the lines and interfere

with the slider during deployment. [Figure 5-24]

4. A new type of connector link, called the “soft link,”

has been approved for use with certain reserve canopies.

[Figure 5-25] Manufactured from Spectra® line, they

loop through the bottom of the suspension line and the

end of the reserve riser. The strength of these soft links

far exceeds that of the metal links when installed properly.

If installed on the reserve, the rigger should have

the manufacturer’s instructions to ensure the correct

installation.

HARNESS

1. When inspecting the harness, start at the riser end,

checking the condition of the webbing and stitching. Pay

particular attention to the security of the steering line

guide rings and the method of stowing the excess steering

line. If these guide rings fail, it can result in fatal consequences

to the user.

2. Check all of the hardware on the harness in the same

manner detailed in the pilot emergency parachute section

in this chapter (page 5-5).

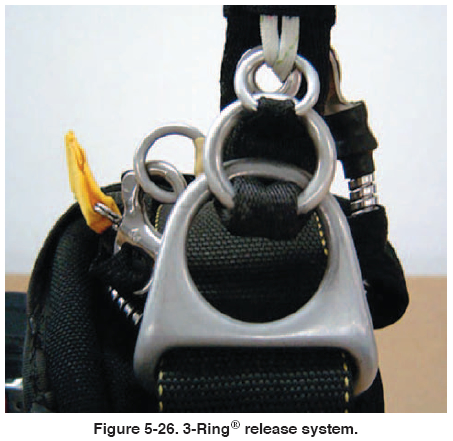

3. Check the canopy release system for wear and operation.

The release in almost universal use today is the 3-Ring®

release system. [Figure 5-26] With this system, it is

imperative that the rigger also checks the release cable

housings for security and cleanliness. Without proper

maintenance, this system can be subject to hard pull

forces and the inability to release properly. Since the successful

operation of the reserve deployment is somewhat

dependent on cleanly releasing the main, a properly operating

release system is necessary. The primary areas for

inspection are the release locator Velcro® on the harness

and the cable housings. Check the housing ends for sharp

edges on the inside of the grommets. If the housings are

tacked to the harness, make sure these are secure. If the

customer did not bring the main canopy with the reserve,

the rigger should encourage the customer to at least bring

the 3-Ring® release handle in for inspection and service.

|