Chapter 5

CONTAINER

In addition to those container areas referenced under the

pilot emergency system, the sport piggyback container

has features unique to this configuration.

1. Check the installation of the AAD, if one is installed,

making sure the stowage pockets, cutter mounts, and control

unit are secure. Check that the cables are routed correctly.

If they are exposed, they may get snagged during

packing and damaged or disconnected. Upon completion,

inspect the condition of the closing loop.

2. Check the Reserve Static Line (RSL). The RSL is not

considered part of the certified reserve system, but if it is

installed, the rigger is responsible for the entire RSL

assembly since it is attached to the ripcord handle, cable,

or housing. This includes the cable housings for tacking

and security, any guide rings used, and the RSL lanyard

itself. Check the release or snap shackle, if used, and any

Velcro® or other positioning or locating methods. An area

frequently overlooked is the RSL attachment ring on the

main risers, which are frequently replaced. [Figure 5-27]

In many cases, the attachment ring does not match up to

the original design. The rigger should inspect the release

handle for proper cable lengths. If the design has only one

riser attached to the RSL, it is imperative that the cables

be trimmed to release the side opposite the lanyard first

so that the reserve is not deployed before the risers are

separated from the harness.

3. Check the main deployment system, of which there are

three basic types in use today. The first is a ripcord similar

to the pilot emergency system. The second type is the

throw-out pilot chute (TOP). The third is the pull-out pilot

chute (POP).

Next, inspect the main ripcord system. Check the ripcord

and main pilot chute the same as with the pilot

emergency system. Inspect the ripcord pocket for

proper holding of the ripcord handle.

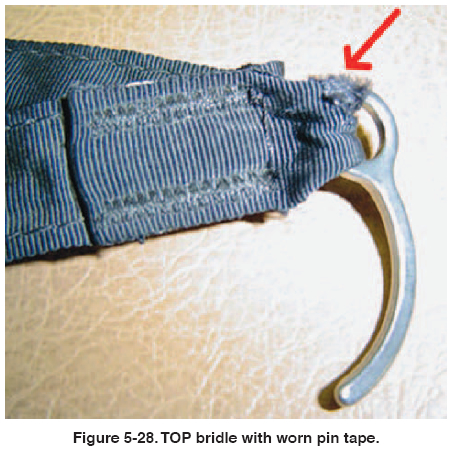

b. For throw-out pilot chutes, inspect the pilot chute fabric

and mesh for holes. Check the TOP handle at the

top of the pilot chute for security, paying special attention

to the tape holding the handle, which is particularly

prone to wear. Check the bridle attachment to the

pilot chute. If it is of a centerline collapsible design,

check the centerline for wear and stretch, and make

sure the length of the bridle is correct. Check the

curved locking pin for wear or damage as well as the

tape, which attaches it to the bridle. [Figure 5-28 on

page 5-16] Check the pilot chute pocket for fit and

wear. Most of today’s installations are what is known

as a “bottom of container” (BOC) configuration. It is

particularly important that the elastic material from

which the pocket is made is in good condition. A

loose pocket can result in a premature deployment of

the main parachute.

c. If repacking a pull-out parachute, check the pilot

chute and bridle in the same manner of the throw-out

parachute inspection. Check the lanyard and handle

for wear.

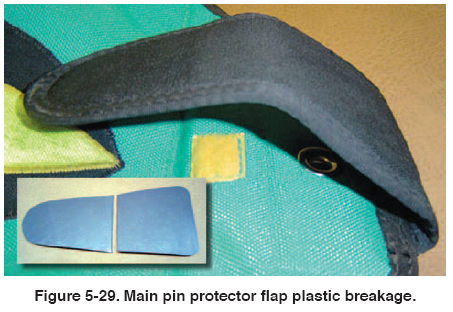

5. If Velcro® is used on the main riser covers, be sure to

check its condition. If plastic, check for breakage and

deformation. If the plastic is excessively deformed, it is

a sign that the covers do not fit properly and may open

prematurely, causing problems.

6. For the container-closing loop, the same criteria applies

as in the pilot emergency parachute. In addition, make

sure the loop material is the same as specified in the

owner’s manual, especially if an AAD is installed. With

certain AADs, a particular type of knot and washer to be

used is specified as well.

|